Pouring forming system for manufacturing prestressed concrete pipe pile

A technology of concrete pipe piles and prestressing, which is applied in the direction of ceramic forming machines, manufacturing tools, mold separation devices, etc., and can solve the problems of many steps and a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

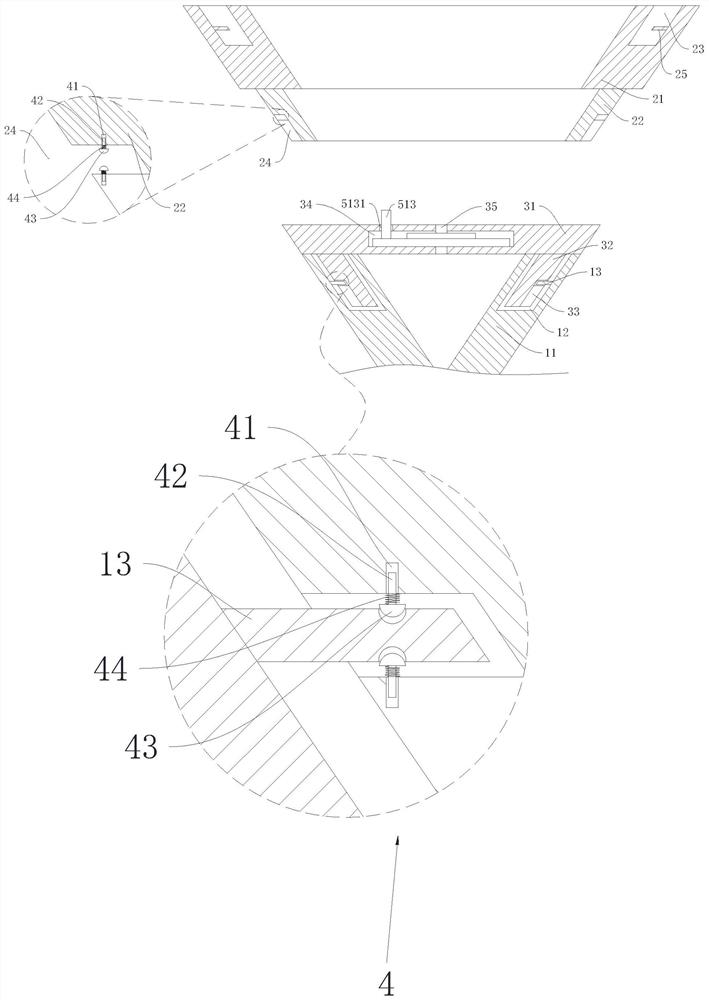

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

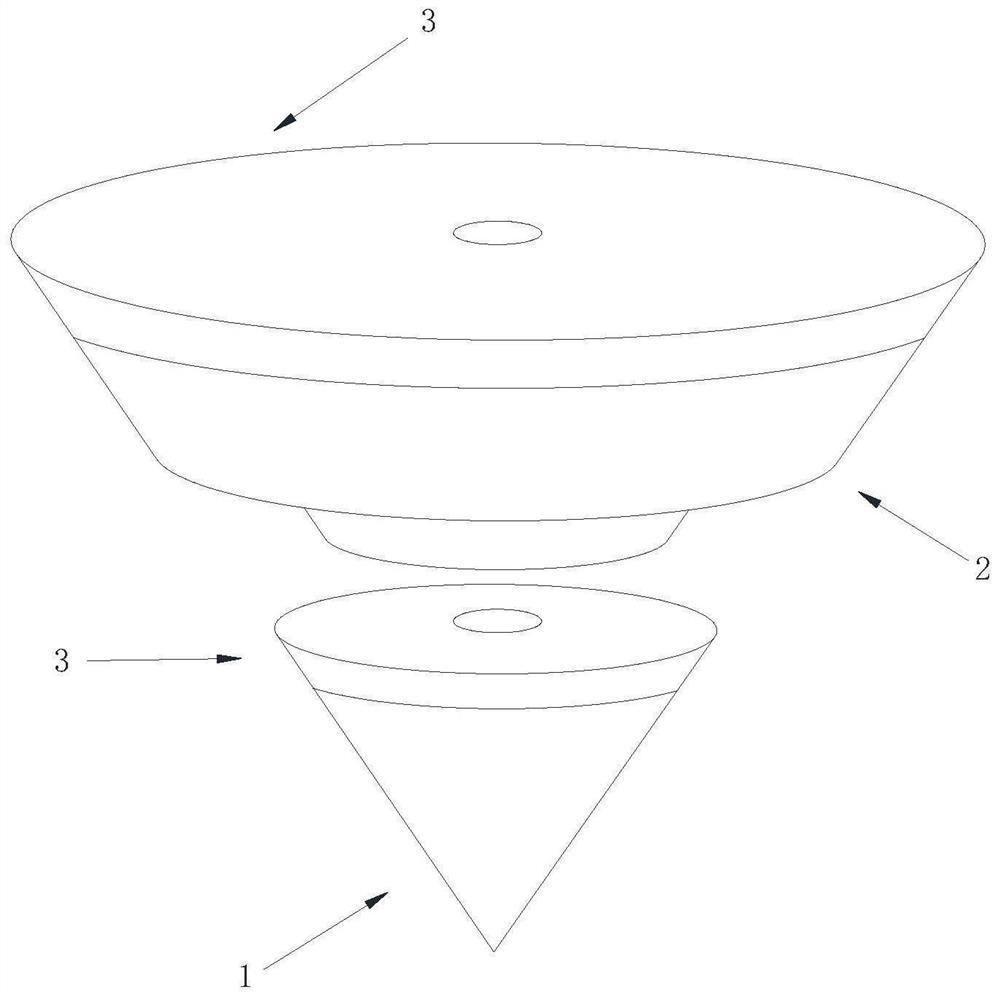

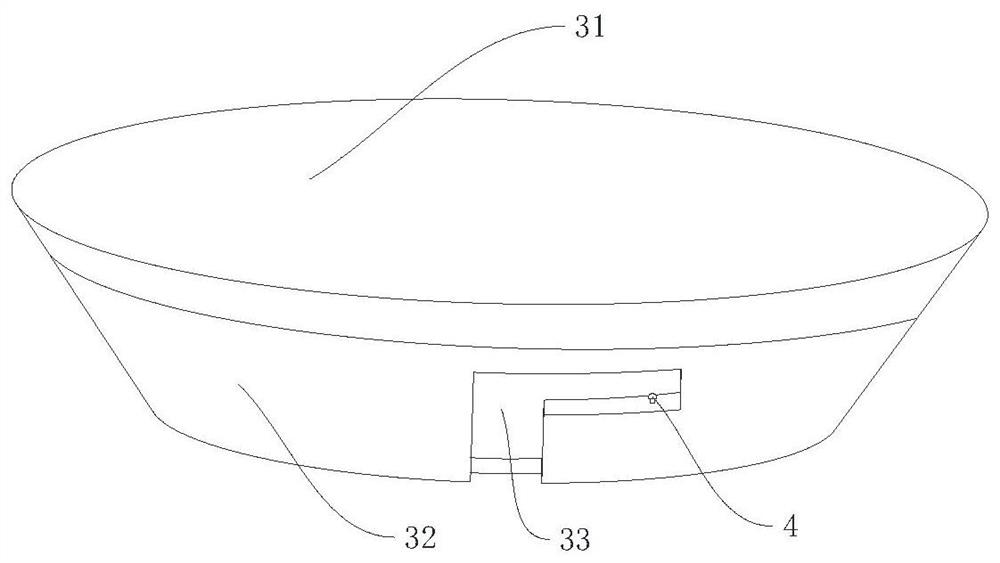

[0028] refer to figure 1 As shown, a pouring and molding system for making prestressed concrete pipe piles includes an injection molding mechanism 1 for pouring and molding, an extension mechanism 2 for changing the size of the tip, and a cover for sealing the injection molding mechanism 1 and the extension mechanism 2 Capping mechanism3.

[0029] refer to figure 1 as well as figure 2 As shown, the injection molding mechanism 1 includes a conical mold 11, a mold groove 12 and a clamping column 13. The upper end surface of the conical mold 11 is circumferentially provided with a mold groove 12, and the clamping column 13 is symmetrically installed on the side wall of the mold groove 12; It should be noted that the shape of the mold groove 12 should be consistent with that of the conical mold 11 , and it should be opened on the upper end surface of the coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com