A low-slump concrete automatic transportation system and construction method for large-slope cavern lining

An automatic transportation and slump technology, applied in wellbore lining, tunnel lining, earthwork drilling, etc., can solve the problem of difficult transportation of concrete, save equipment and labor costs, reduce the occurrence of concrete temperature cracks, and improve construction quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

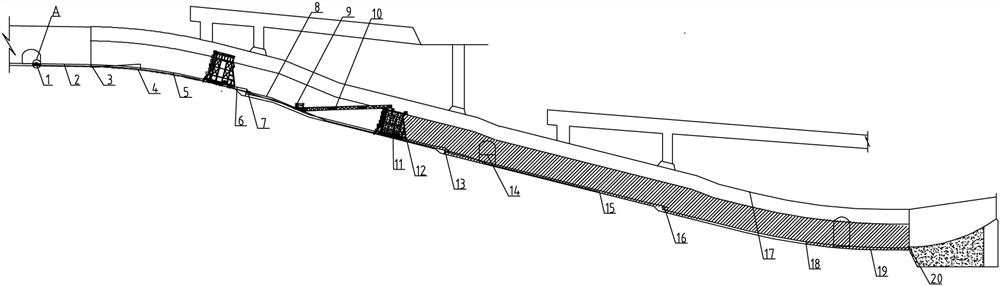

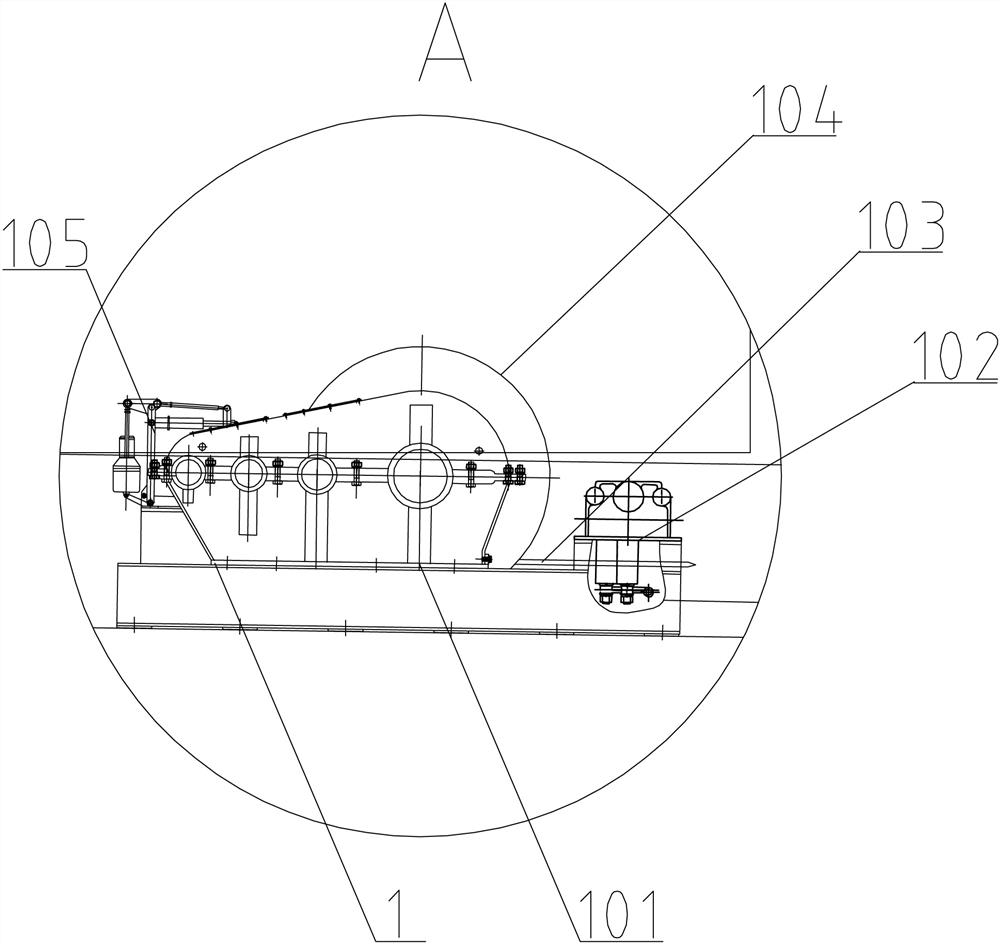

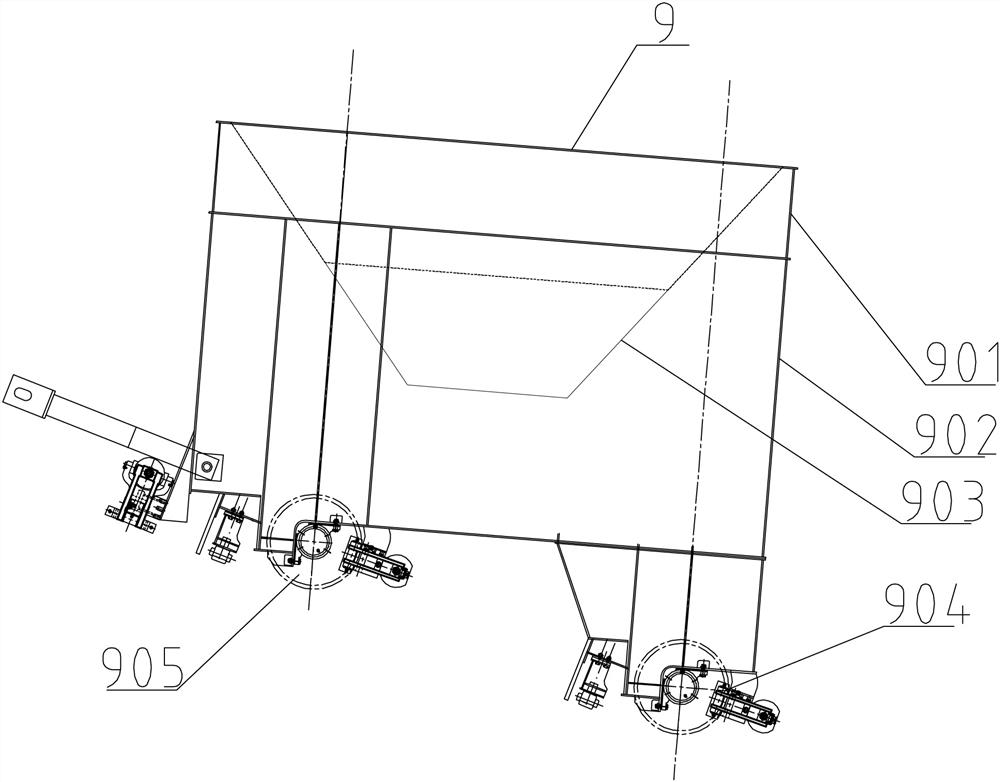

[0048] see Figure 1-5 , an automatic transportation system for low-slump concrete in the lining of large-slope caverns, which includes a frequency conversion hoist 1 fixed on the upper flat section 2 of the flood discharge tunnel, and the upper flat section 2 of the flood discharge tunnel is set at the starting point 3 of the dragon's tail section Previously, after the starting point 3 of the Longluowei section, there are successively the Woqi curve section 4, the slope section 15, the anti-arc section 18 and the lower flat section 19, and together constitute the Longluowei; the floor lining 5 of the entire Longluowei A trolley track 6 is laid on the top, and a material transport trolley 9 is arranged on the trolley track 6. The material transport trolley 9 is connected with the winch of the frequency conversion hoist 1 through a hoisting wire rope and drives it to move along the trolley track 6; A side wall lining trolley 12 is slidingly fitted on the trolley track 6, and th...

Embodiment 2

[0073] The construction method of using the automatic transport system for lining low-slump concrete in large-slope caverns, the general construction principle is: the sequence of concrete construction is from downstream to upstream; it includes the following steps:

[0074] Step 1: Transport the 5-8cm low-slump concrete to the Longluowei unloading point with a rebuilt dump truck;

[0075] Step 2, unloading the concrete on the restructured dump truck to the transport trolley 9;

[0076] Step 3, the material transport trolley 9 is powered by the frequency conversion winch 1, and walks along the trolley track;

[0077] Step 4, the material transport trolley 9 transports the concrete material to the self-adjusting angle vertical feeding structure 10 for unloading, and the self-adjusting angle vertical feeding structure 10 runs with a belt for feeding;

[0078] Step five, the self-adjusting angle vertical feeding structure 10 transports the concrete to the telescopic horizontal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com