External sleeve of automatic steel ladle flow guiding device

An external sleeve and ladle technology, applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of increasing the safety hazards of oxygen burning operators, increasing inclusions, disrupting the production rhythm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

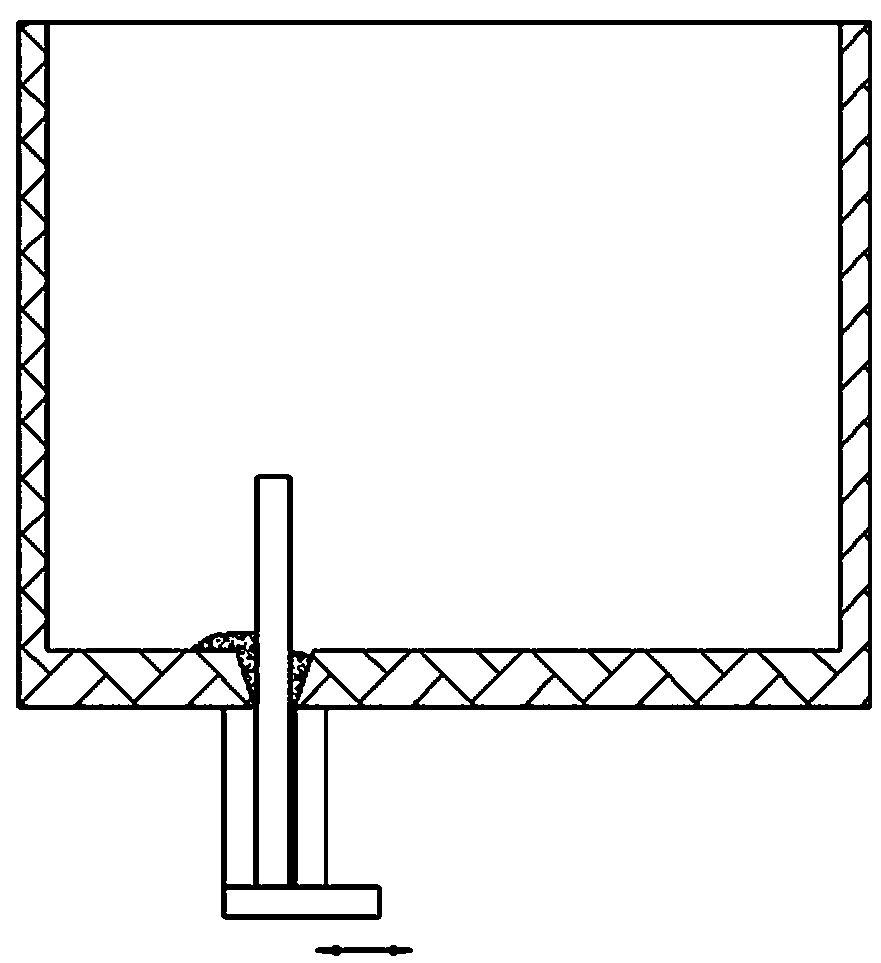

[0018] figure 1 It is an effect diagram of drainage sand filling effect diagram of a ladle automatic drainage device used in a steelmaking system disclosed on the prior art authorization announcement number CN 101543882 B authorization announcement date 2011.02.23. There is less quicksand, and steel slag will flow into the conical space, resulting in a decrease in casting rate.

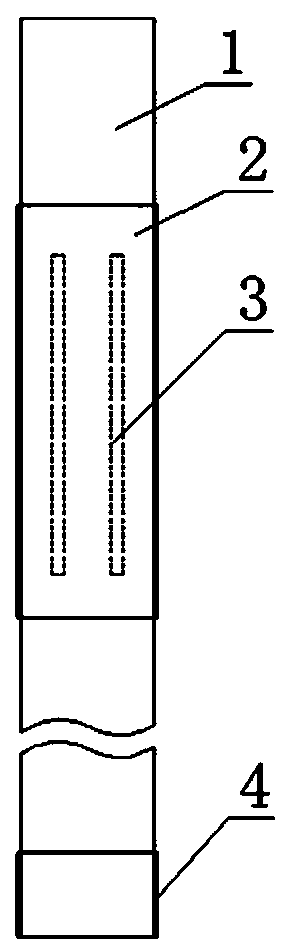

[0019] Such as figure 2 The outer casing of the ladle automatic drainage device shown in -5 of the present invention can fill the space between the drainage rod and the nozzle seat brick with drainage sand, has a high casting rate, is easy to operate, and saves labor and materials.

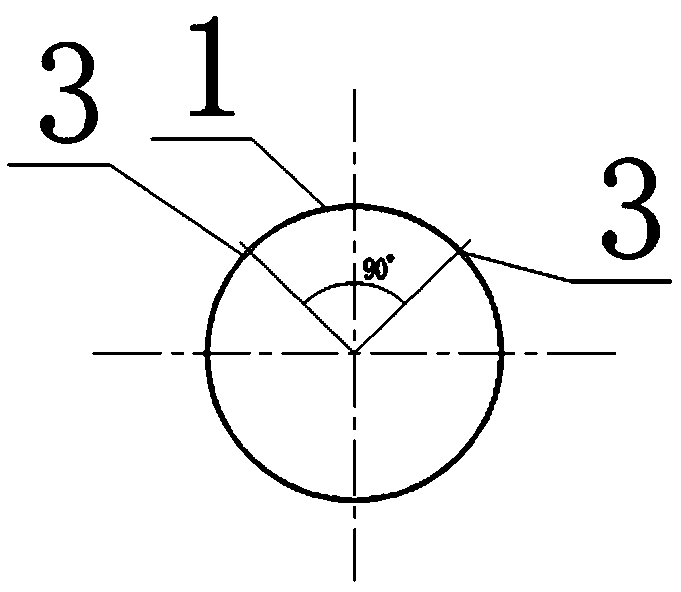

[0020] The outer casing of the ladle automatic drainage device has a thin-walled steel cylinder 1 containing drainage sand. The upper end of the thin-walled steel cylinder is closed, and the lower end is an open structure. The lower end of the thin-walled steel cylinder is sealed by low-temperature melting plastic 4. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com