External template applicable to steel-concrete composite steel corrugated plate arch bridge and culvert

A corrugated plate and outer formwork technology, applied in the field of steel corrugated plate structure, can solve the problems of inconvenient arch structure connection, uneven surface, low machining accuracy, etc., to improve construction convenience, strong overall performance, and good shock resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

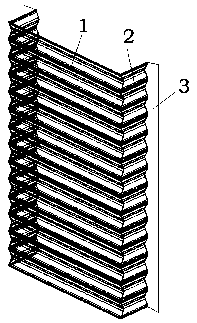

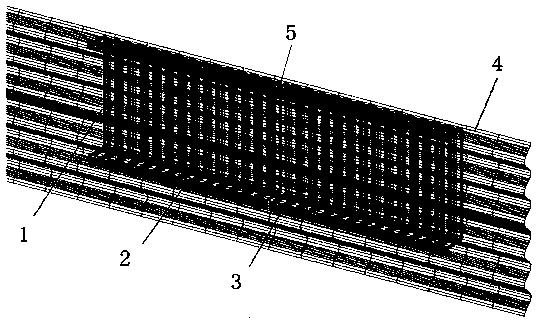

[0014] The present invention is composed of a plurality of formwork segments connected, and each formwork segment is composed of a top plate 1, a side plate 2 and a fixed side 3 respectively.

[0015] figure 1 It is shown that the top plate 1 and the side plate 2 are respectively rectangular small steel corrugated plates, and the fixed side 3 is a long flat steel plate. Their connection structure is that the two side plates 2 are vertically connected to both sides of the top plate 1 respectively, and the bottom sides of the two side plates 2 are respectively vertically connected with the fixed side 3, and the fixed side 3 is evenly distributed with screws along the length direction. hole.

[0016] figure 1 It shows that the length direction of the crests and troughs of the top plate 1 is perpendicular to the length direction of the top plate 1 , and the crests and troughs of the side plate 2 are correspondingly connected with the peaks and troughs of the top plate 1 . Since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com