Roughening device with spraying unit

A chiseling and pneumatic device technology, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of large manpower consumption, complex structure, heavy workload, etc., to reduce labor intensity, safe and reliable construction, and reduce reaction effect on impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

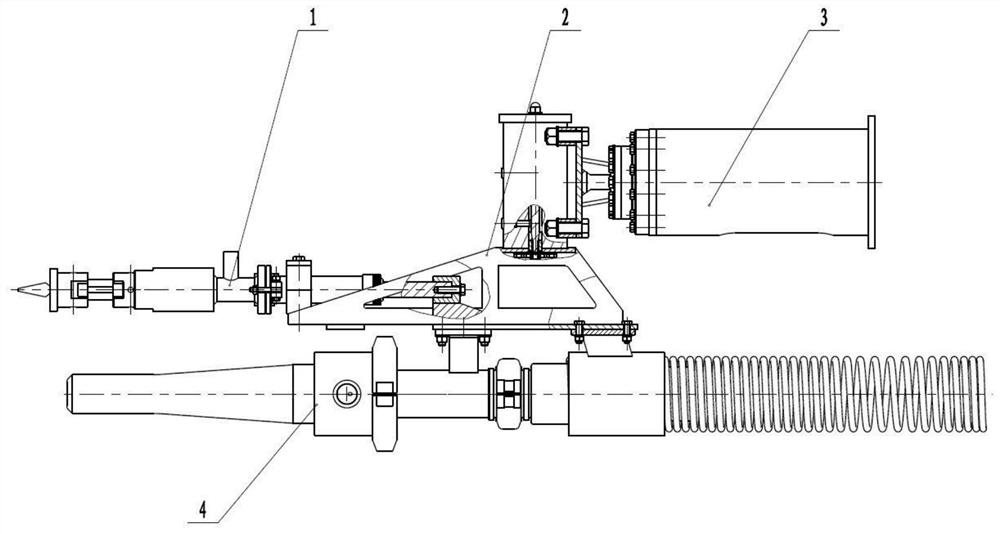

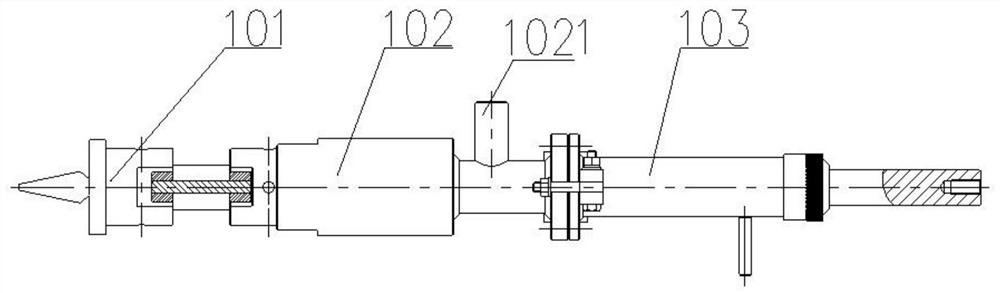

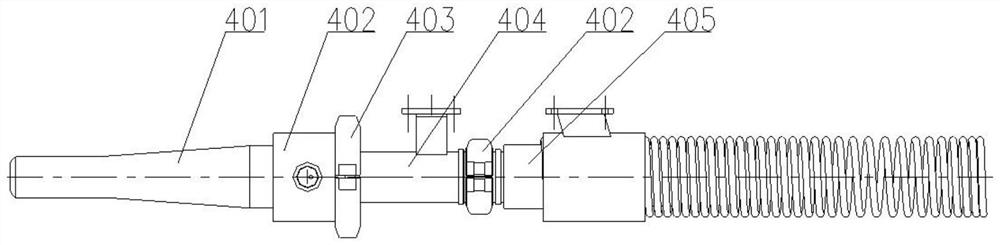

[0024] refer to figure 1 , a chiseling device with a spray unit, comprising a connecting frame and a spraying unit 4 and a chiseling unit 1 arranged on the connecting frame; Mechanism 103, the output end of the pneumatic device is connected with the chisel, the other end of the pneumatic device is connected with the buffer mechanism, and the buffer mechanism is arranged on the connecting frame; at the same time, the pneumatic device is provided with an external interface 1021, and the external interface is externally connected to the high-pressure air flow pipe The pneumatic device provides the axial impact power of the chisel to realize the chisel function of the chisel; the buffer mechanism is used to reduce the axial impact of the chisel unit on the connecting frame, the chisel is more stable, and it is convenient to control the chisel accuracy. The pneumatic device is a common pneumatic structural part in the existing chisel machine; the pneumatic device includes parts suc...

Embodiment 2

[0029] The difference between this embodiment and Implementation 1 lies in the difference of the steering device. The steering device of this embodiment includes a first rotary cylinder and a second rotary cylinder; the first rotary cylinder and the second rotary cylinder are vertically arranged, and the first rotary cylinder The output end is connected perpendicular to the connecting frame to connect the chiseling unit on the frame and the horizontal direction of the injection unit, and the output end of the second rotary cylinder is connected perpendicular to the first rotary cylinder to connect the chiseling unit on the frame to the spraying unit. Steering in the vertical direction of the unit.

[0030]It should be noted that the devices in the first embodiment and the second embodiment both include a pneumatic control system, and the pneumatic control system is configured with reference to the conventional pneumatic control system to control the movement of the cylinder.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com