Action regulation fabricated formwork for U-box combined continuous beam segment cast-in-place

A technology for activity adjustment and combined formwork, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., and can solve problems such as separation, time-consuming, and troublesome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

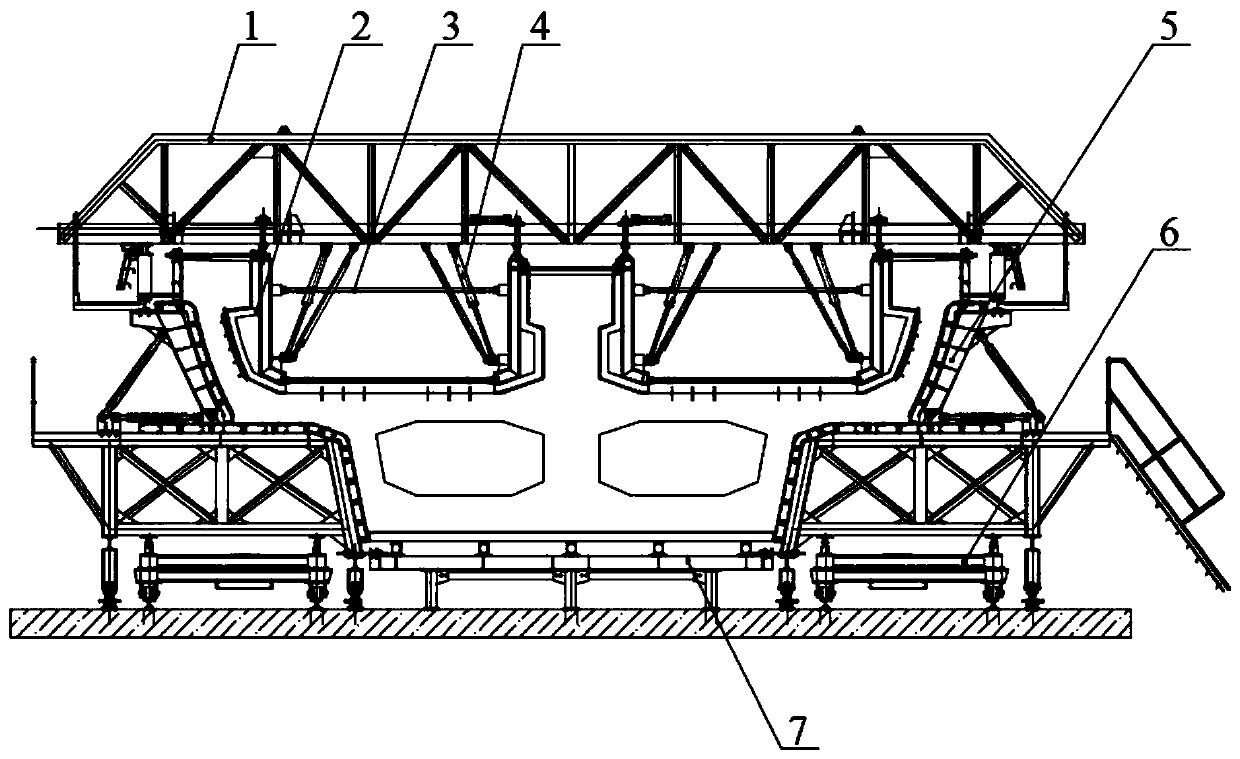

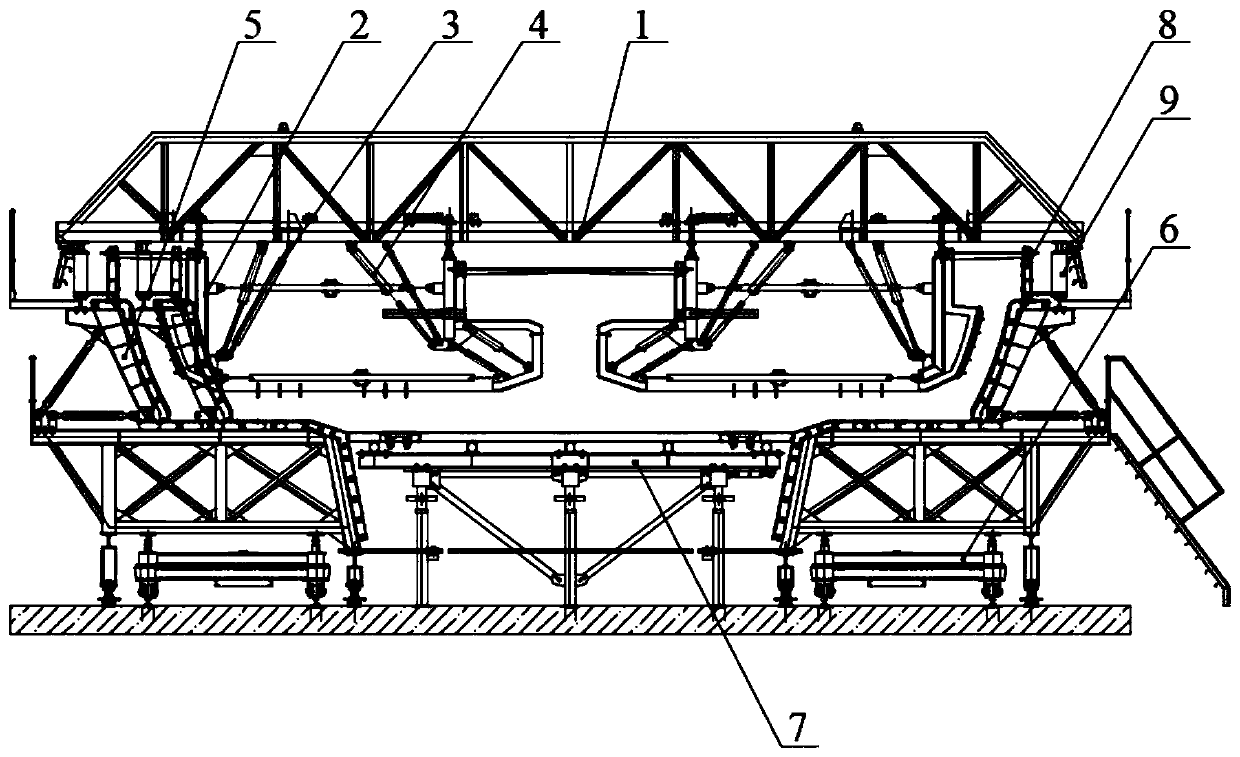

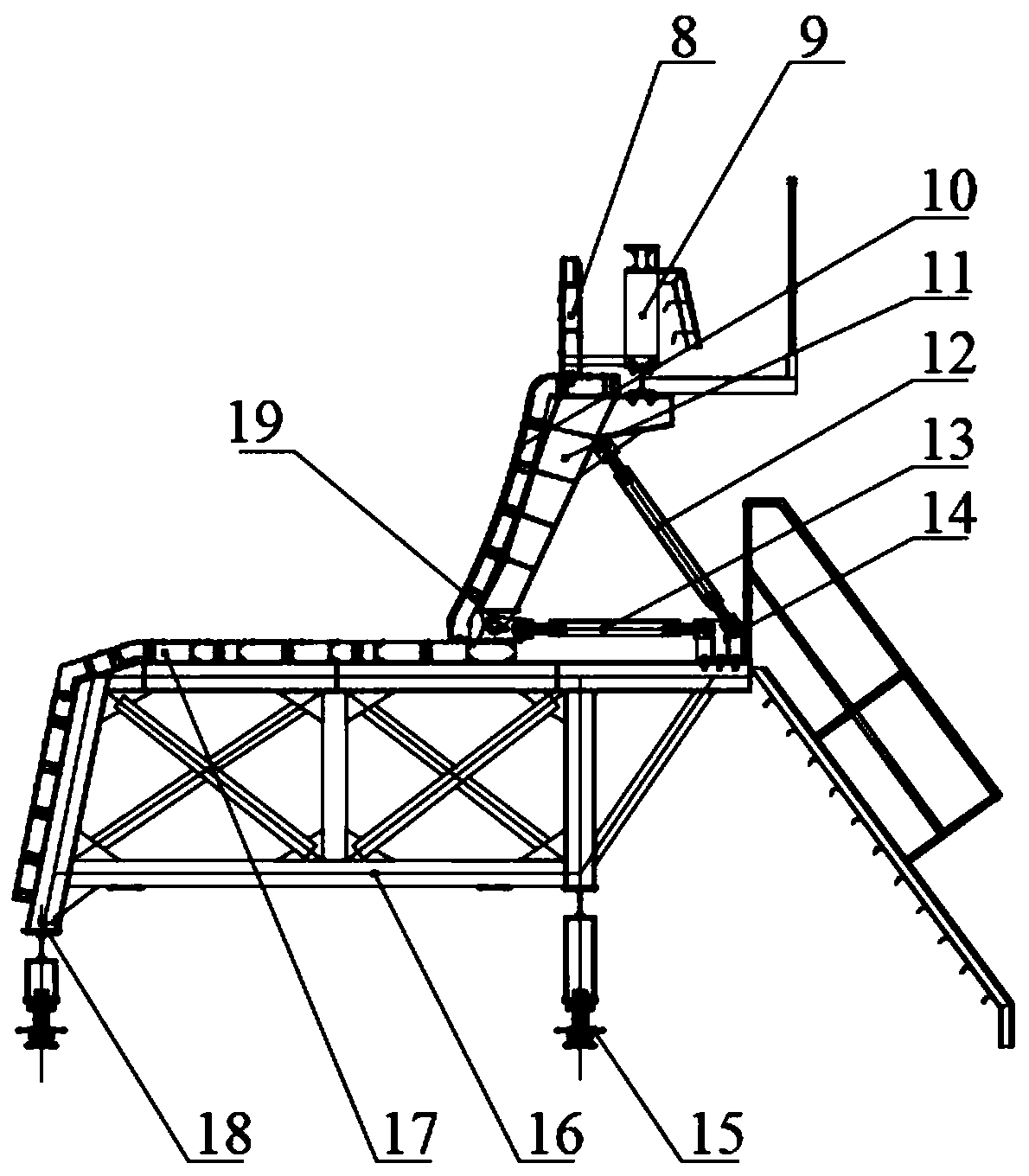

[0050] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

[0051] A U-box combined continuous beam section cast-in-place movable adjustable combined formwork, including an inner mold, a bottom mold 7, and side molds 5 that are arranged oppositely on both sides of the continuous beam pouring direction and are respectively detachably connected to the inner mold and the bottom mold The inner mold includes a top crossbeam 1, an inner mold hydraulic cylinder 4 and multiple groups of mold flaps 2 oppositely arranged, wherein the bottom of the top beam is hinged with the mold flap and the inner mold hydraulic cylinder, and the output end of the inner mold hydraulic cylinder is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com