Seismic Isolation Method for Prefabricated Concrete Structure Floors

A concrete structure and prefabricated technology, which is applied in the direction of earthquake resistance, building components, protective buildings/shelters, etc., can solve the problems of poor vibration isolation effect, avoid corrosion damage, and improve the effect of lateral movement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

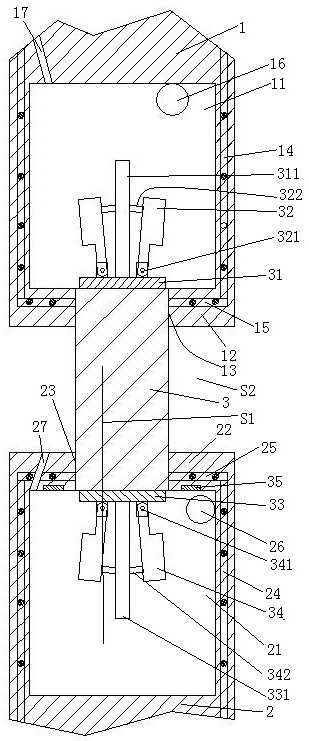

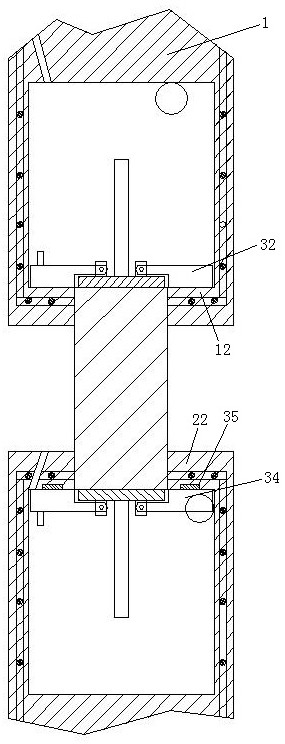

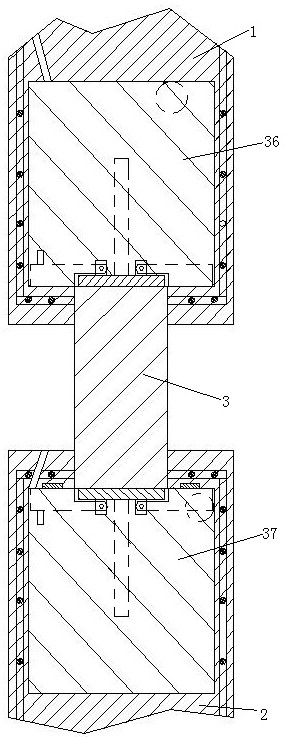

[0021] see figure 1 , figure 2 and image 3 , a prefabricated concrete structure storey isolation method,

[0022] The first step is to set an upper connection hole 11 on the lower end surface of the upper concrete column 1, and the opening of the upper connection hole is provided with an inner flange 12 of the upper hole part to form an upper closing opening 13, and an upper hole is provided in the hole wall of the upper connection hole The upper flange part reinforcement frame 15 is provided with the upper flange part reinforcement skeleton 14 and the upper hole part inner flange to improve the structural strength of the hole wall of the upper connecting hole and the upper hole part inner flange. The upper connecting hole is provided with an upper grouting hole 16 and an upper exhaust hole 17 . A lower connecting hole 21 is set on the upper end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com