A crosslinked polyethylene insulating layer surface flatness detection method based on edge detection

A cross-linked polyethylene, edge detection technology, applied in image data processing, instruments, computing and other directions, can solve the problems of unstable detection quality, low efficiency and low accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

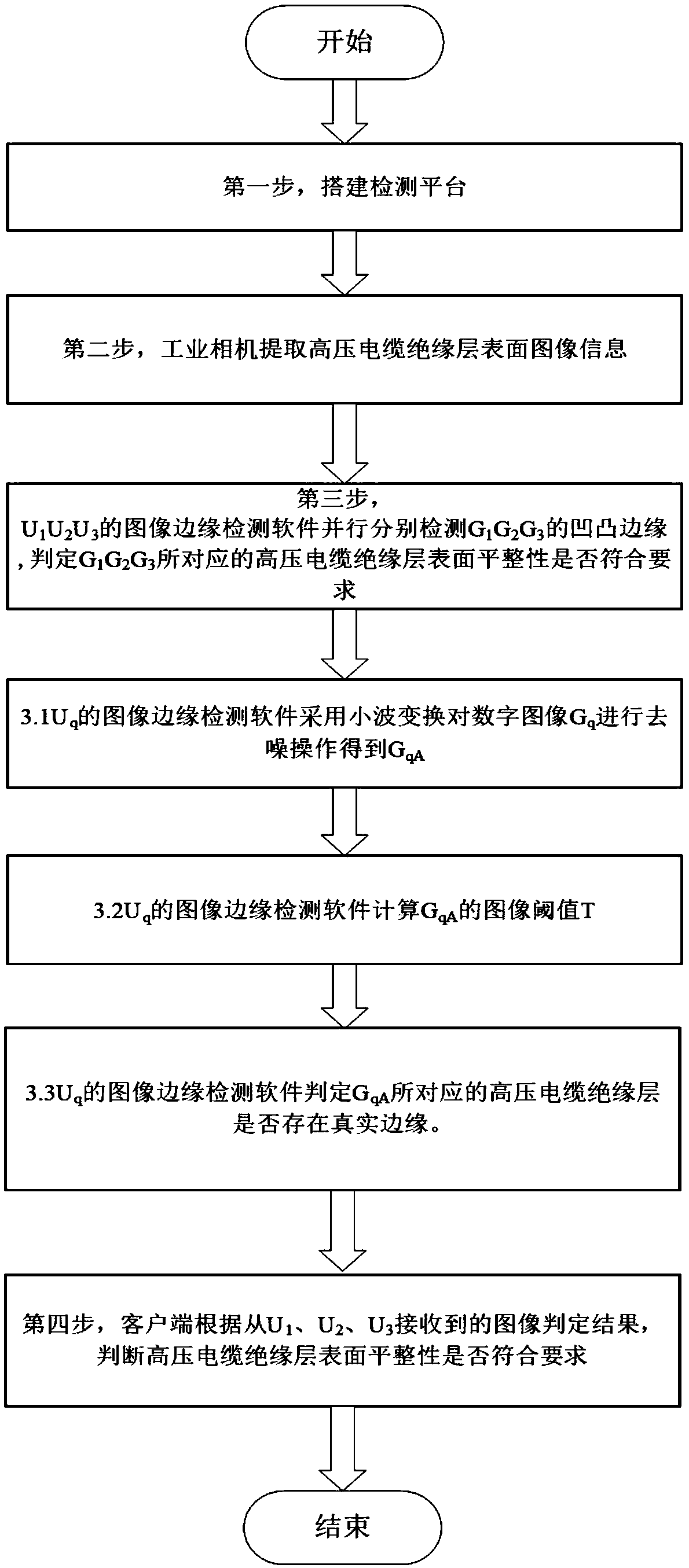

[0052] figure 2 Is the overall flow chart of the present invention. Such as figure 2 Shown, the present invention comprises the following steps:

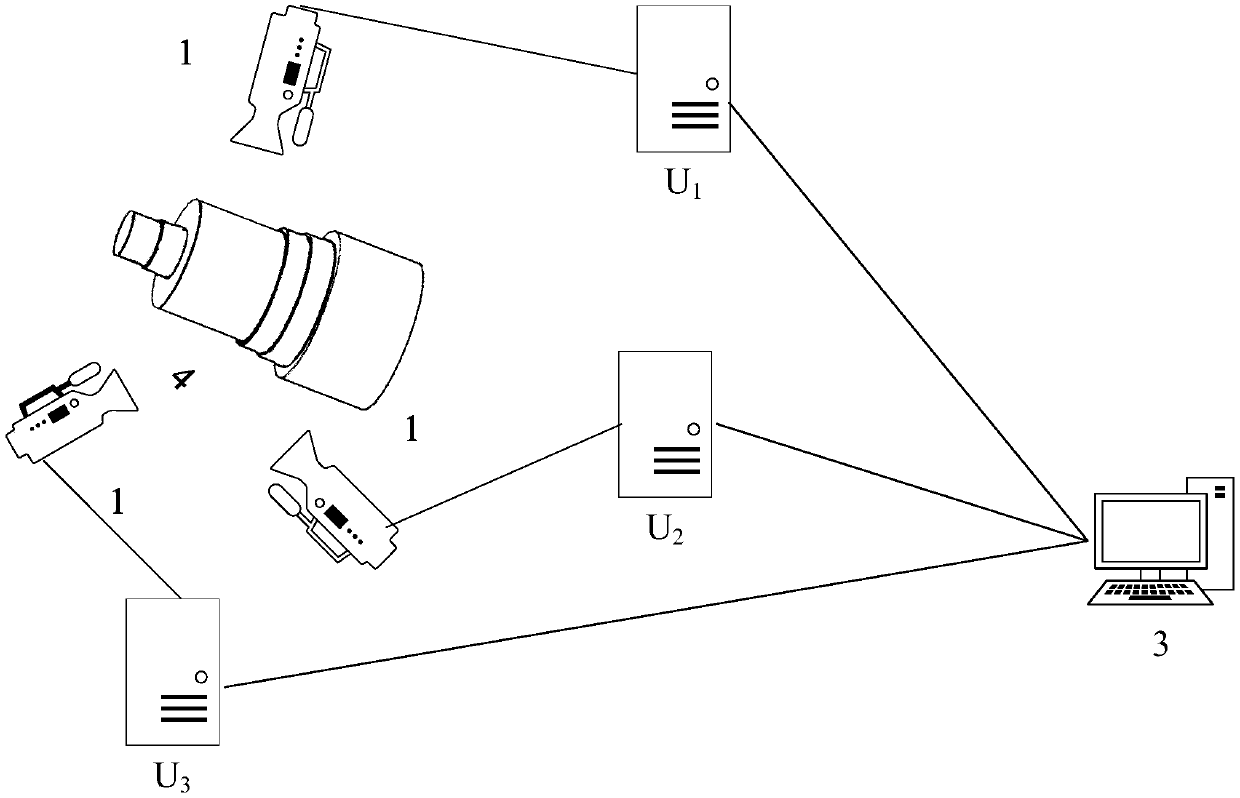

[0053] The first step is to deploy the industrial camera 1 and digital image processor at the designated location, and build a detection platform, such as figure 1 As shown, the method is:

[0054] 1.1 The high-voltage cable 4 deploys three industrial cameras 1 at intervals of 2 meters, and the three industrial cameras 1 are evenly deployed at the top, bottom left, and bottom right of the same section of the high-voltage cable 4, and each industrial camera 1 forms a 120° three-dimensional space Angle, to capture the image information of the surface of the insulation layer of the high-voltage cable 4. The industrial camera 1 selects a CCD industrial line scan camera, wherein the parameter requirements are: the video system selects PAL system as 768×576, the pixel depth is 12Bit, selects the progressive exposure mode, the exposu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com