Anti-overspeed belt conveyor

A technology for belt conveyors and conveyor belts, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., and can solve problems such as speeding accidents, waste, and speed out of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

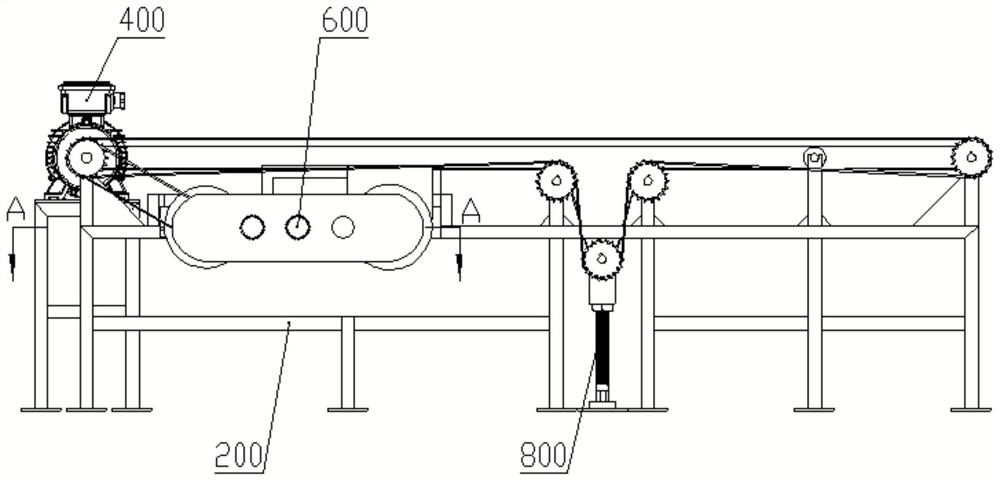

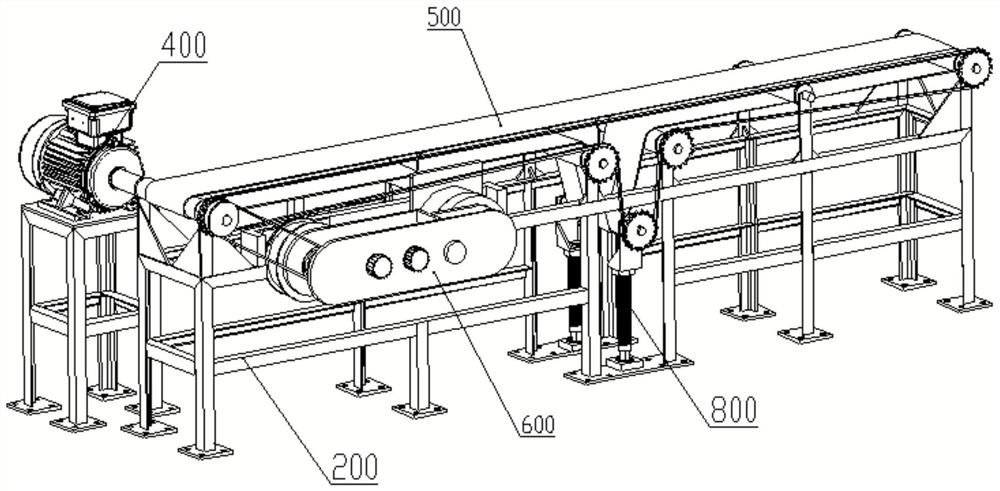

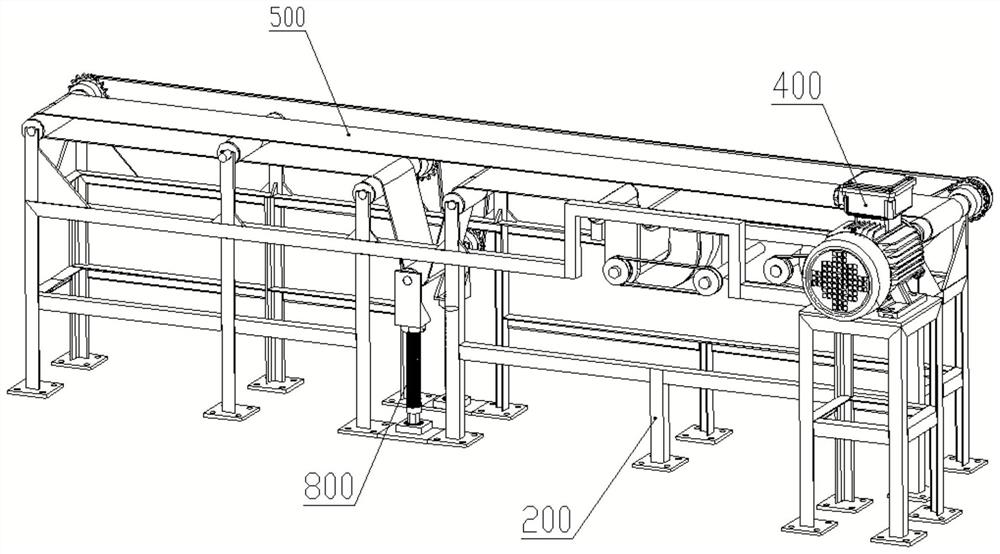

[0113] Such as Figure 1-16 As shown, this embodiment provides an anti-overspeed belt conveyor, including:

[0114] frame body 200;

[0115] There are at least two belt rollers 700, which are rotatably connected with the frame body 200;

[0116] The conveying belt 500 is wound on the belt roller 700 and is used for conveying materials;

[0117] The driving mechanism 400 is connected with the conveying belt 500 and is used to drive the conveying belt 500 to rotate;

[0118] The roller speed limiting mechanism 100 is connected with the belt roller 700 to prevent the belt roller 700 from running at an overspeed;

[0119] The speed-regulating operating mechanism 600 is connected with the roller speed-limiting mechanism 100 and is used to adjust the running resistance of the roller speed-limiting mechanism 100;

[0120] The belt adjustment mechanism 800 is connected with the conveying belt 500 and used for adjusting the tension of the conveying belt 500 .

[0121] Among them, ...

Embodiment approach 2

[0180] refer to Figure 17-Figure 21 The main difference between this embodiment and Embodiment 1 is that the roller speed limiting mechanism 100 uses a uniform speed mechanism 130 and an adjusting mechanism 140 of different structures, while the frame body 200, the belt roller 700, the conveyor belt 500, the driving mechanism 400, and the roller limiter The housing 110 of the speed mechanism 100, the arrangement of non-Newtonian fluid, the connection of the rotating shaft 120, and the stirring working principle and beneficial effect of the first stirring blade 135 are all the same as those of Embodiment 1, and the differences will be described in detail below.

[0181] The constant speed mechanism 130 of this embodiment adopts two radially evenly distributed first stirring blades 135, which also includes:

[0182] The sliding sleeve 131 is sleeved on the rotating shaft 120, and the sliding sleeve is provided with a chute 136;

[0183] The slider 132 is embedded in the chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com