Preparation method of multi-layer glaze daily-use porcelain

A technology for porcelain and daily use, which is applied in the field of preparation of multi-layer glaze-changing daily-use porcelain, which can solve the problem of poor thermal stability of ceramic products, lack of energy saving and consumption reduction, and inability to use a new technology for mixing and decorating with opaque kiln and colored cosmetic soil, etc. problems, to achieve the effect of improving the overall aesthetics, reducing the firing cost, and improving the overall purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

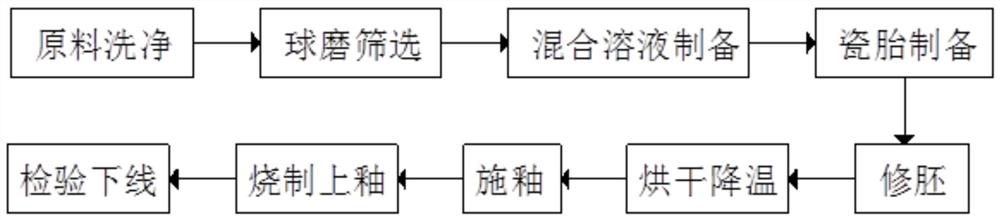

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] Please refer to figure 1 ,in figure 1 It is a process flow chart of a preferred embodiment of the preparation method of the multi-layer glazed daily-use porcelain provided by the present invention. The preparation method of multi-layer glazed porcelain for daily use comprises the following raw materials in parts by weight:

[0031]15-25 parts of aluminum oxide, 50-70 parts of silicon dioxide, 0.05-0.1 parts of ferric oxide, 0.08-0.6 parts of calcium oxide, 1.5-2.5 parts of magnesium oxide, 0.01-0.1 parts of potassium oxide, 2 parts of sodium oxide -5 parts, 0.01-0.05 parts of titanium dioxide, 008-0.24 parts of zirconium dioxide, 3-5 parts of diboron trioxide, 0.01-0.1 parts of barium oxide, 15-25 parts of coloring material and 40-50 parts of deionized water;

[0032] Its preparation steps are as follows:

[0033] B. Cleaning of raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com