Preparation method of honeycomb-shaped wear-resistant ceramic block

A wear-resistant ceramic and honeycomb technology, which is applied in the field of preparation of wear-resistant ceramic blocks, can solve problems such as limited effect, and achieve the effects of reducing the total amount, reducing the sintering temperature and improving the wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

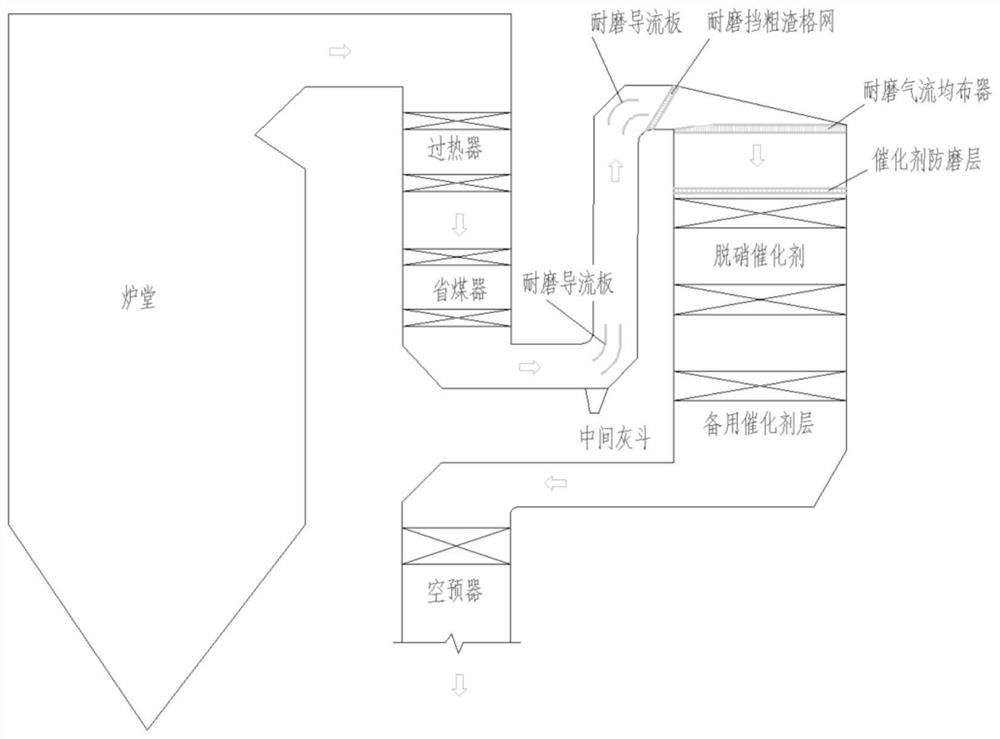

[0043] The invention provides a preparation method of a honeycomb wear-resistant ceramic block, comprising mixing cordierite powder, mullite powder, kaolin, talc, potassium feldspar, quartz and calcium carbonate, adding binder and xanthan gum, After preparing the solution of sodium alginate and sodium polyacrylate, kneading the obtained mud, kneading the mud, forming it into a honeycomb shape, drying and sintering, so as to prepare the obtained honeycomb wear-resistant ceramic block. Among the above raw materials, the thermal expansion coefficient of cordierite is 0.5×10 -6 ~1.0×10 -6 K -1 , which mainly plays the role of reducing the expansion coefficient; mullite plays the role of increasing the strength and wear resistance of the ceramic block, and its thermal expansion coefficient is not large (4.7×10 -6 K -1 ); and kaolin, talc and quartz can react to form cordierite with a porous structure during the sintering process, so kaolin, talc and quartz can improve the sinter...

Embodiment 1

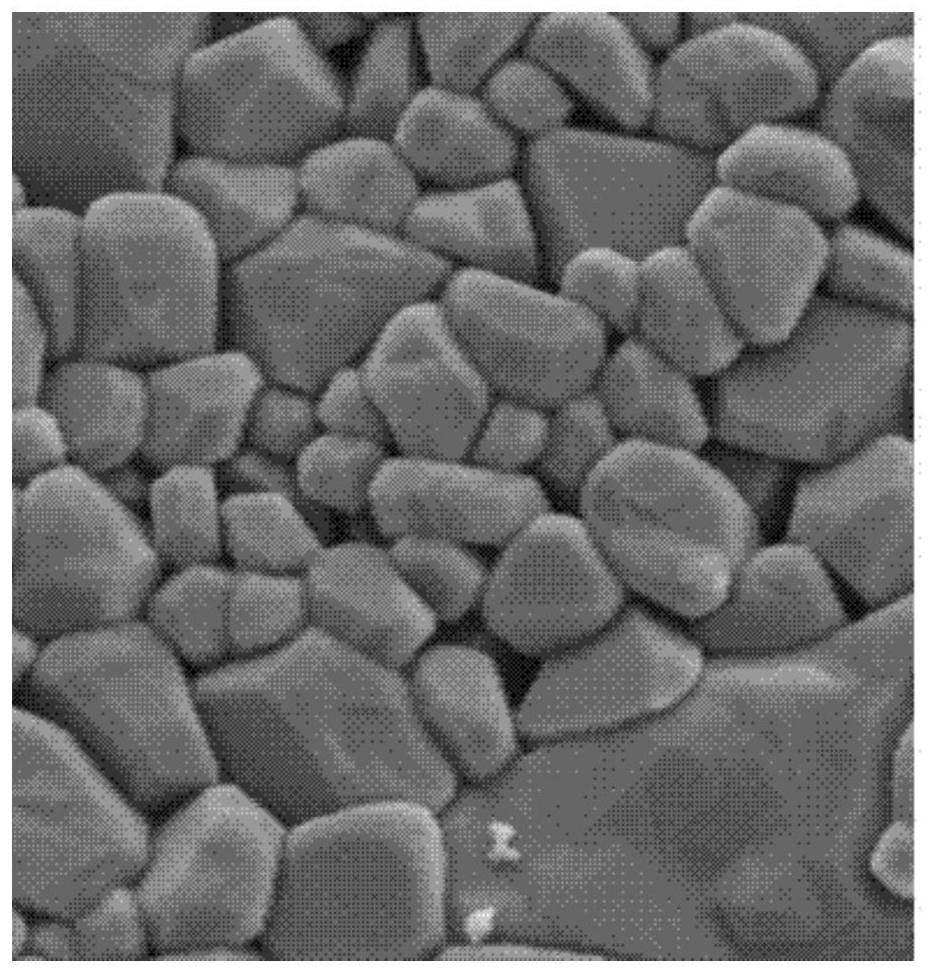

[0064] After mixing 45wt% of cordierite powder, 20wt% of spherical mullite powder passed through a 300-mesh sieve, 21wt% of calcined kaolin, 6wt% of talc, 5wt% of potassium feldspar, 2wt% of fused quartz, and 1wt% of calcium carbonate, add ceramic components The hydroxypropyl methylcellulose of total mass 4.5wt%; Then add the xanthan gum-sodium alginate-sodium polyacrylate aqueous solution of ceramic component gross mass 28%, wherein xanthan gum, sodium alginate and sodium polyacrylate The concentrations were 0.7wt%, 0.2wt% and 2.4wt%, respectively, to obtain sludge. Then knead the mud for 20 minutes, knead the mud, vacuum knead the mud, and extrude it into a honeycomb green body. After the green body is microwave dried and cut at a power of 80kW, it is kept at 1330°C for 2 hours to sinter the green body to obtain a density of 2.12g / cm 3 , the porosity is 21%, the flexural strength is 18MPa, and the coefficient of thermal expansion at room temperature -600°C is 1.9×10 -6 K ...

Embodiment 2

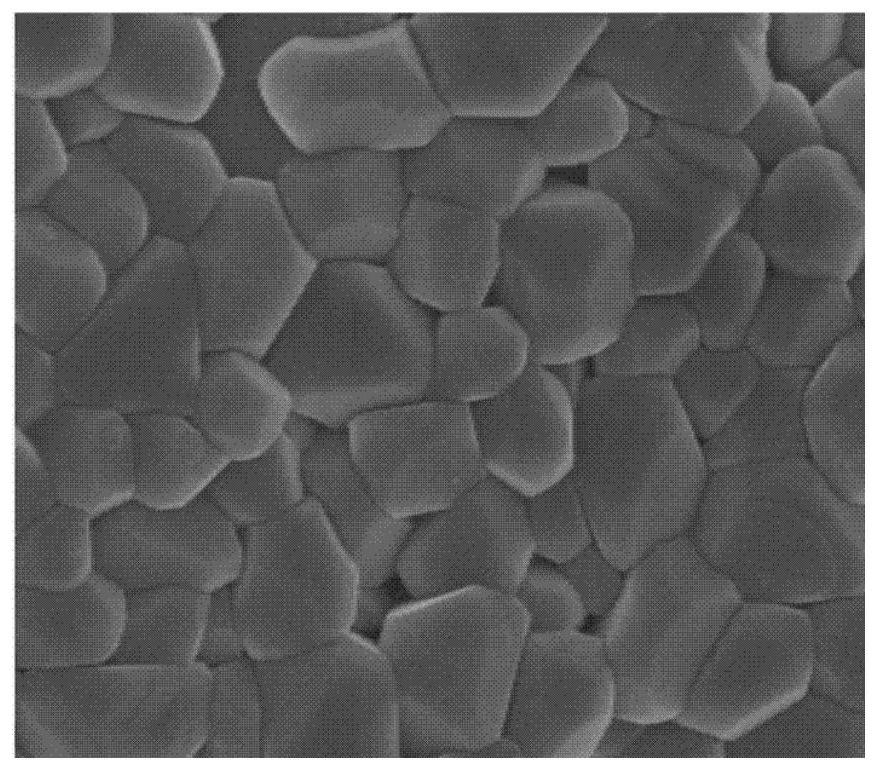

[0072] After mixing 40% cordierite powder, 25% spherical mullite powder passed through a 300-mesh sieve, 20% calcined kaolin, 7% talc, 4% potassium feldspar, 2% fused quartz and 2% calcium carbonate, add ceramic components The hydroxypropyl methylcellulose of total mass 4%; Then add the xanthan gum-sodium alginate-sodium polyacrylate aqueous solution of ceramic component total mass 26%, the concentration of xanthan gum, sodium alginate and sodium polyacrylate respectively At 0.7%, 0.2% and 2.4%, blends were obtained. After kneading the mixed material for 20 minutes, carry out mud refining, vacuum mud refining, and extrude into a honeycomb green body. After the green body is microwave dried and cut at a power of 80kW, it is sintered at 1330°C for 3 hours to obtain a density of 2.09g / cm 3 , the porosity is 24%, the flexural strength is 23MPa, and the coefficient of thermal expansion at room temperature -600°C is 2.2×10 -6 K -1 Cordierite-mullite wear-resistant honeycomb ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com