Remote wireless temperature measuring system

A remote wireless and wireless data transmission technology, applied in the field of temperature monitoring systems, can solve the problems of high power consumption, interference, high cost and maintenance costs, and achieve the effect of reducing power consumption and reducing the probability of mutual collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

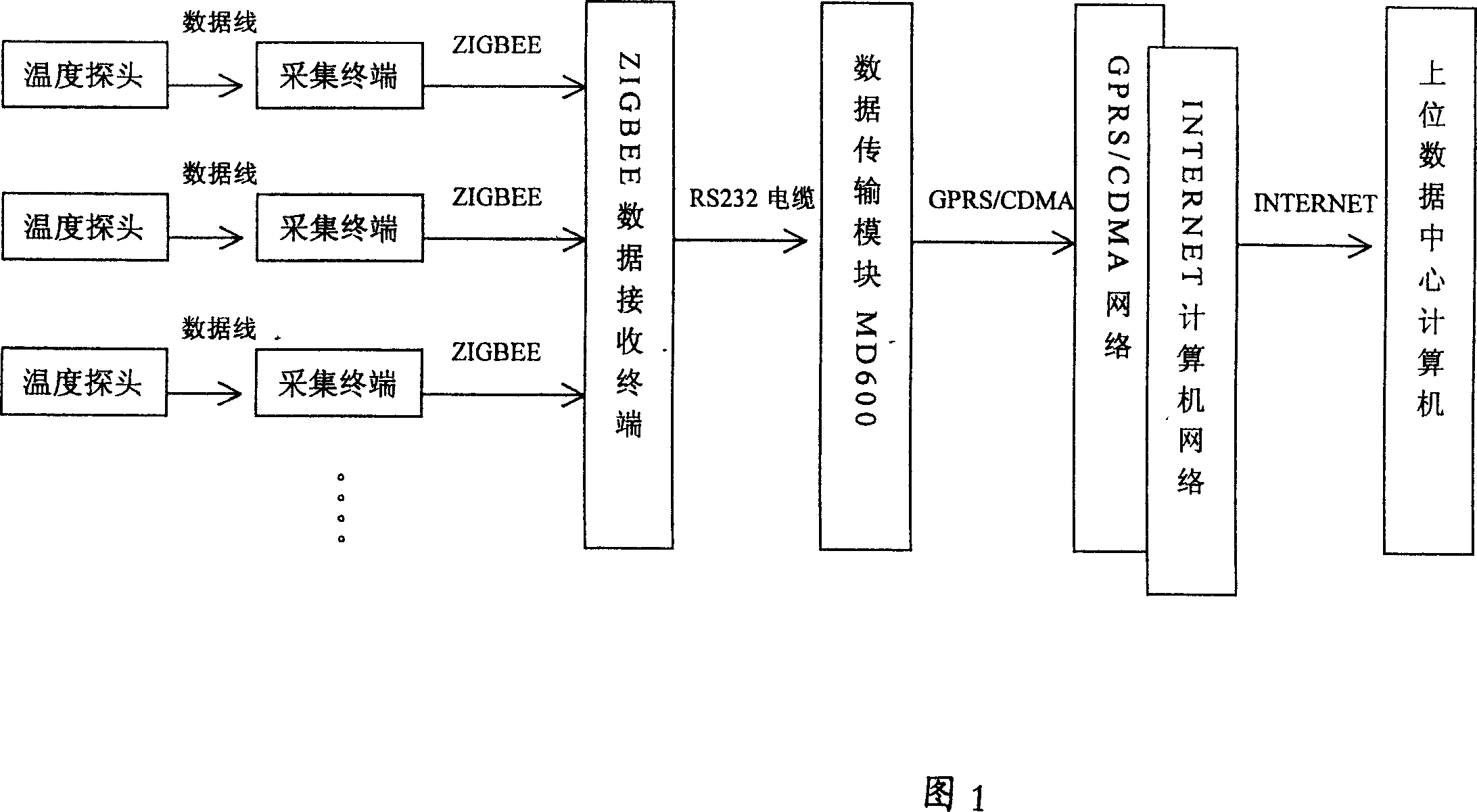

[0015] As shown in Figure 1, the present invention is that temperature probe is connected with ZigBee temperature collection terminal through data line, and ZigBee temperature collection terminal utilizes Zigbee network to transmit the data after collecting to ZigBee data receiving terminal, and ZigBee data receiving terminal communicates with wireless data through RS232 data line The transmission terminal (this embodiment adopts GPRS intelligent wireless data terminal MD-600) is connected, and the wireless data transmission terminal utilizes the GPRS / CDMA network to send data to the network of the designated IP address, and the management server (the present embodiment adopts the CK-DC1 .0 data center software computer) connected to the network to read data. The temperature probe is a wireless temperature detection probe with a radio frequency transceiver; the ZigBee ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com