Combined type gas atomization powder preparation equipment

A pulverizing equipment and gas atomization technology, which is applied in the field of compound gas atomization pulverizing equipment, can solve the problems that the purity of metal powder is not high enough, affect the performance of processed products, and the purity is low, and achieve less collision probability and quality. Light, oxygen-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

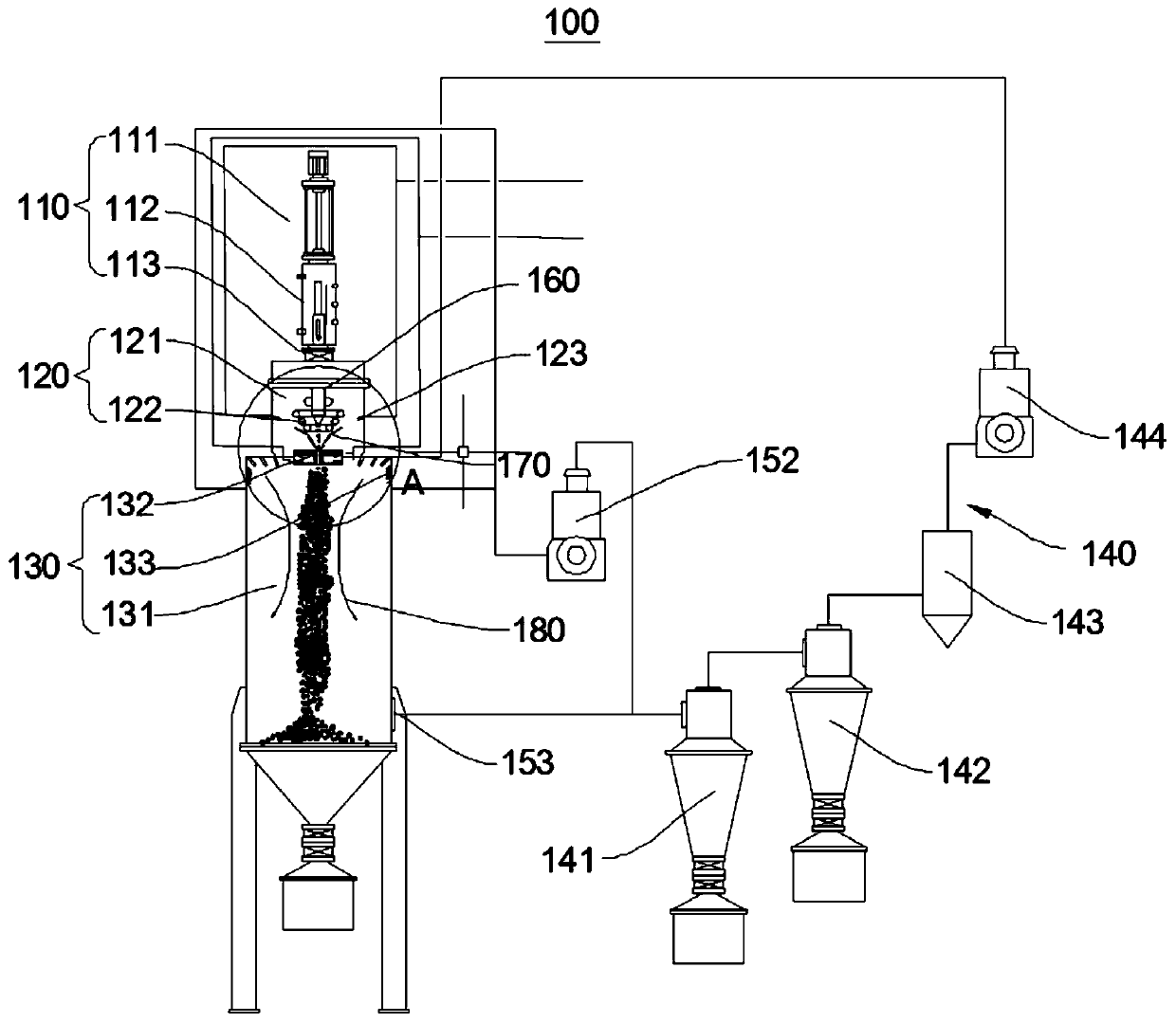

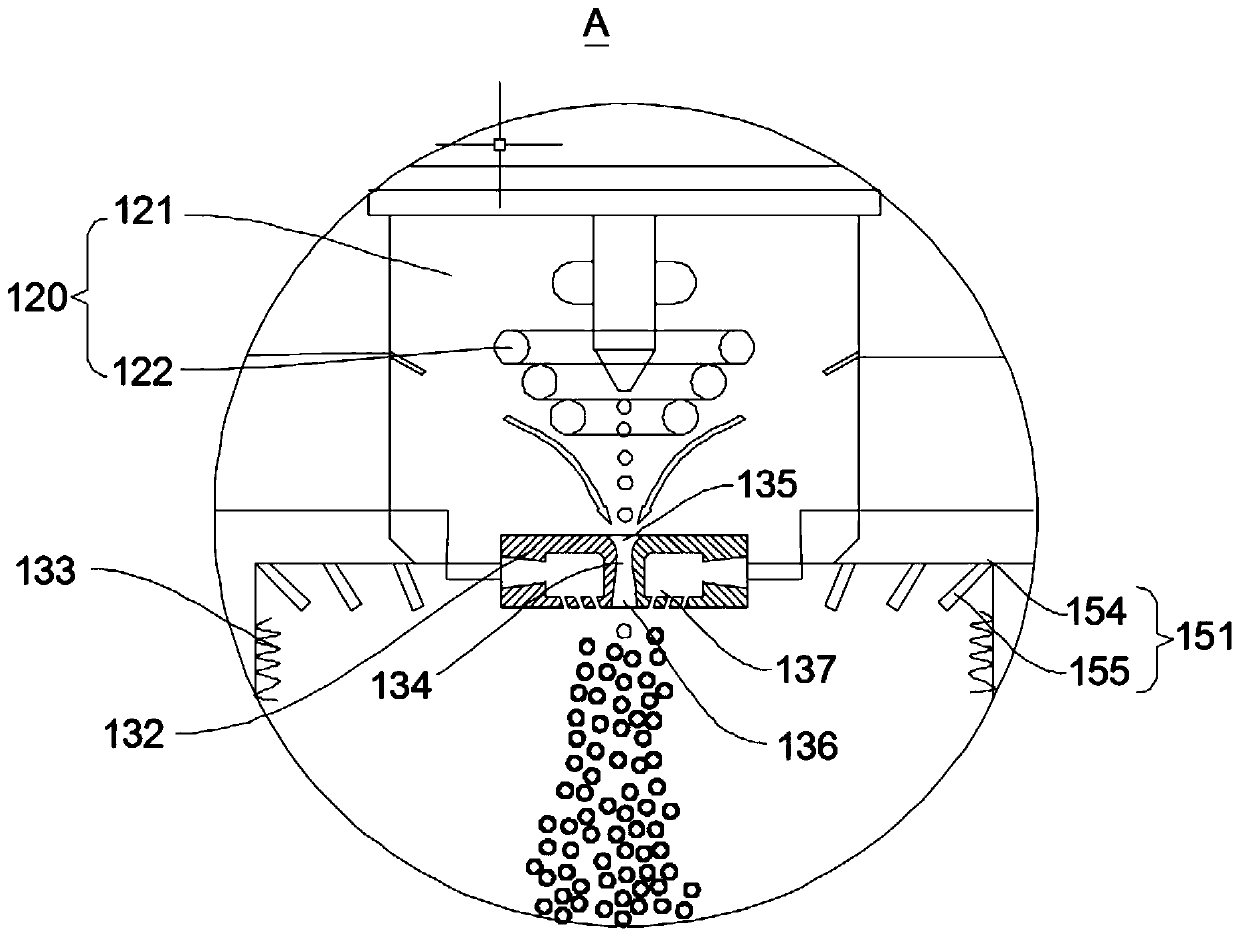

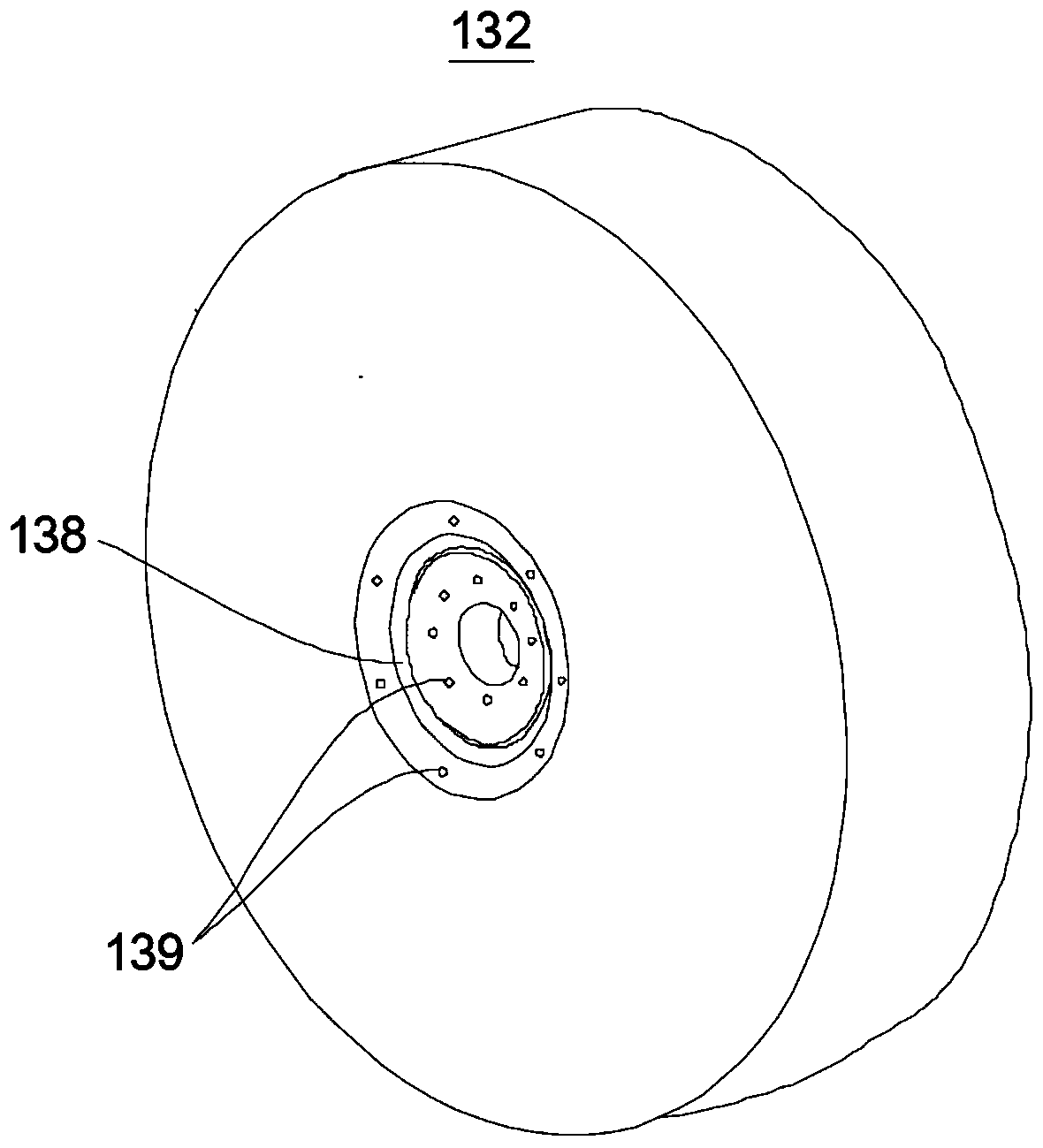

[0037] Please refer to figure 1 , the present embodiment provides a composite gas atomization powder making equipment 100, which includes a feeding system 110, a smelting system 120, an atomization system 130, a circulating gas system 140 and an ultrasonic generator 133. The feeding system 110, the smelting system 120 and the atomizing system 130 are sealed and connected in sequence. The circulating gas system 140 is connected to the smelting system 120 and the atomizing system 130 through pipelines. The ultrasonic generator 133 is installed in the atomization system 130 . The ultrasonic waves emitted by the ultrasonic generator 133 can realize the synergistic effect of the ultrasonic energy field coupling gas atomization, and further disperse and break the molten metal droplets.

[0038] Please continue to refer to figure 1, the feeding system 110 includes a driving device 111 , a pipe body 112 and a clamping piece 113 for clamping a metal rod 160 . The driving device 111...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com