Device and method for controlling DC motor to lower roller shutter door at constant speed

A technology of DC motors and control devices, applied in the direction of DC motor speed/torque control, door/window protection devices, control systems, etc. Working at high pressure and high temperature for a long time, reducing production costs and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments.

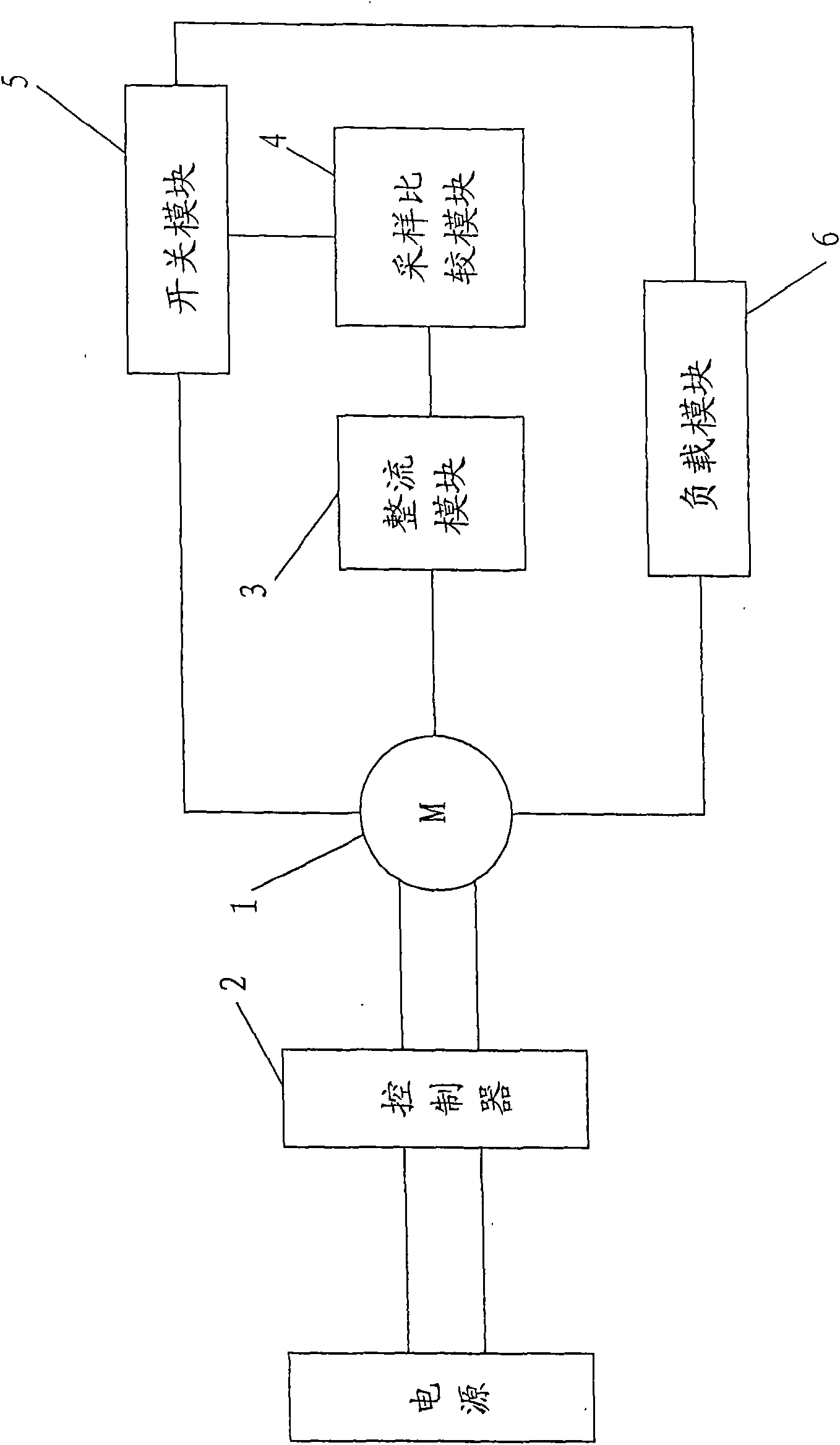

[0024] image 3 Shown is a preferred embodiment of the present invention, including a rectification module 3 , a sampling module 4 , a comparison module 7 , a switch module 5 and a load module 6 .

[0025] The rectifier module 3 is connected in parallel to the two ends of the DC motor 1, and rectifies the voltage signal at both ends of the DC motor 1. In this embodiment, a bridge rectifier circuit is selected, such as Figure 5 As shown, the bridge rectifier circuit is formed by two-to-two connection of four diodes. This is a known technology, so it will not be described again.

[0026] The output end of the rectification module 3 is connected to the sampling end of the sampling module 4 , and the sampling module 4 samples the rectified voltage value and transmits the voltage value to the connected comparison module 7 .

[0027] The output end of the sampling module 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com