Refrigerating equipment based on hardness control

A technology for freezing equipment and hardness control, which is applied in the direction of dairy products, frozen desserts, milk preparations, etc. It can solve the problem that the actual hardness cannot be reflected, the quality of frozen products such as yogurt or ice cream in the refrigeration equipment is reduced, and the constant speed of the stirring motor cannot be realized. Operation and other problems, to achieve the effect of quality assurance and precise hardness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

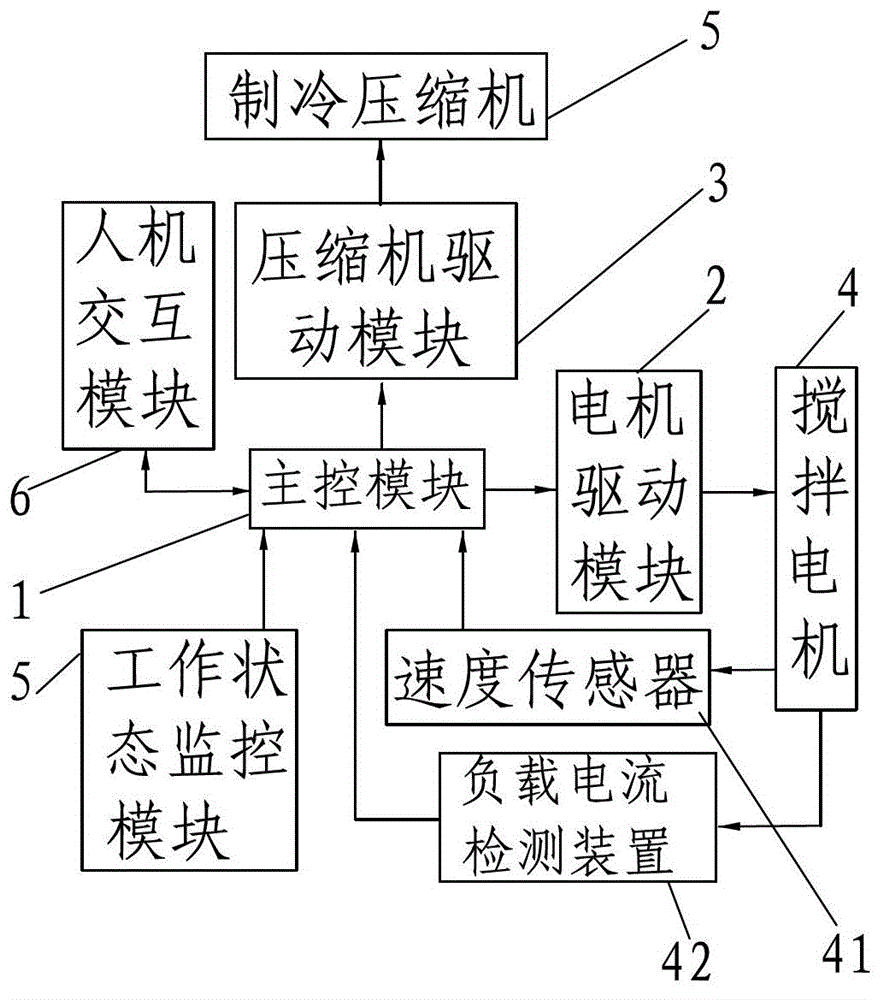

[0013] Attached below figure 1 The present invention is further elaborated:

[0014] A refrigeration device based on hardness control, the refrigeration device includes a main control module 1, the main control module 1 is used to set a motor drive module 2 and a compressor drive module 3, and the motor drive module 2 and the compressor drive module 3 respectively drive stirring The motor 4 and the refrigerating compressor 5 , the stirring motor 4 is used to set a speed sensor 41 and a load current detection device 42 , and the speed sensor 41 and the load current detection device 42 are used to set the main control module 1 .

[0015] For the convenience of speed regulation and control, as a preferred embodiment, the stirring motor 4 of this embodiment is a brushless DC motor.

[0016] As a preferred embodiment, the speed sensor 41 is a Hall position sensor, which has the characteristics of accurate sensing.

[0017] In the present invention, the main control module 1 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com