Landfill leachate treatment equipment

A technology for landfill leachate and treatment equipment, which is applied in the field of landfill leachate treatment equipment, can solve the problems of complex overall process, general sludge drying effect, and inability to treat sludge, and achieves the effect of improving drying effect and prolonging residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

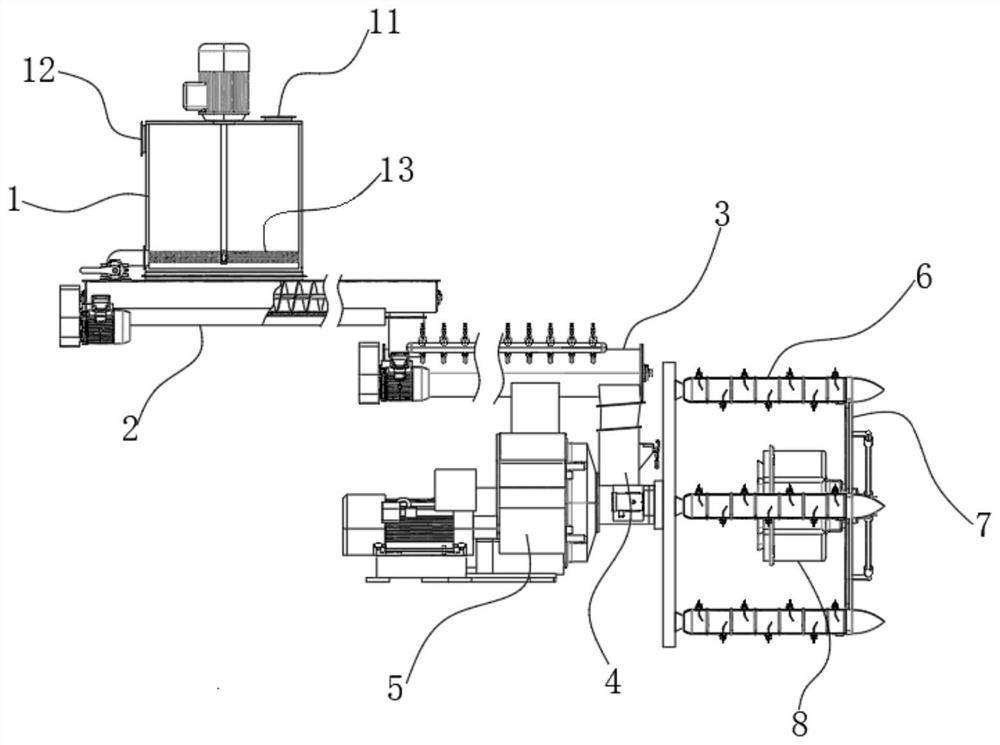

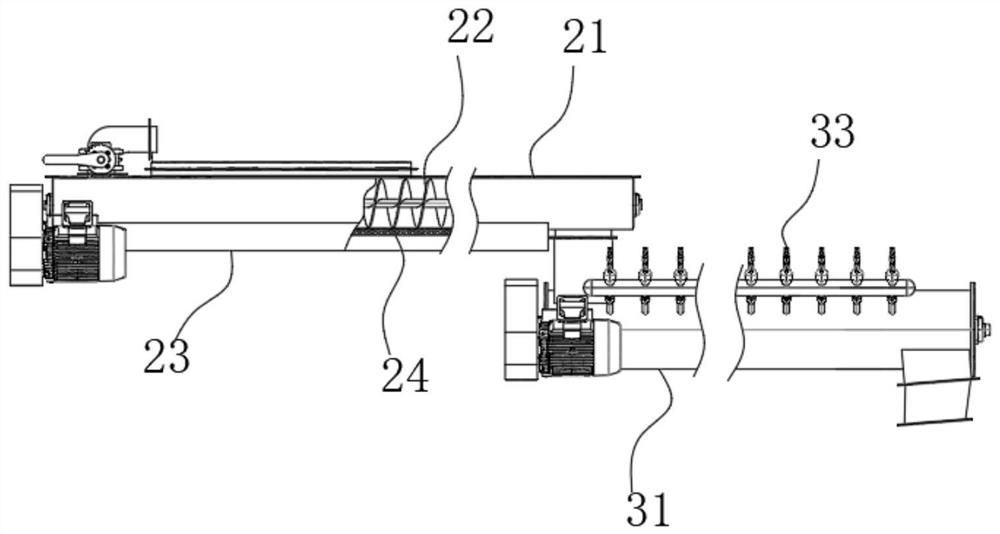

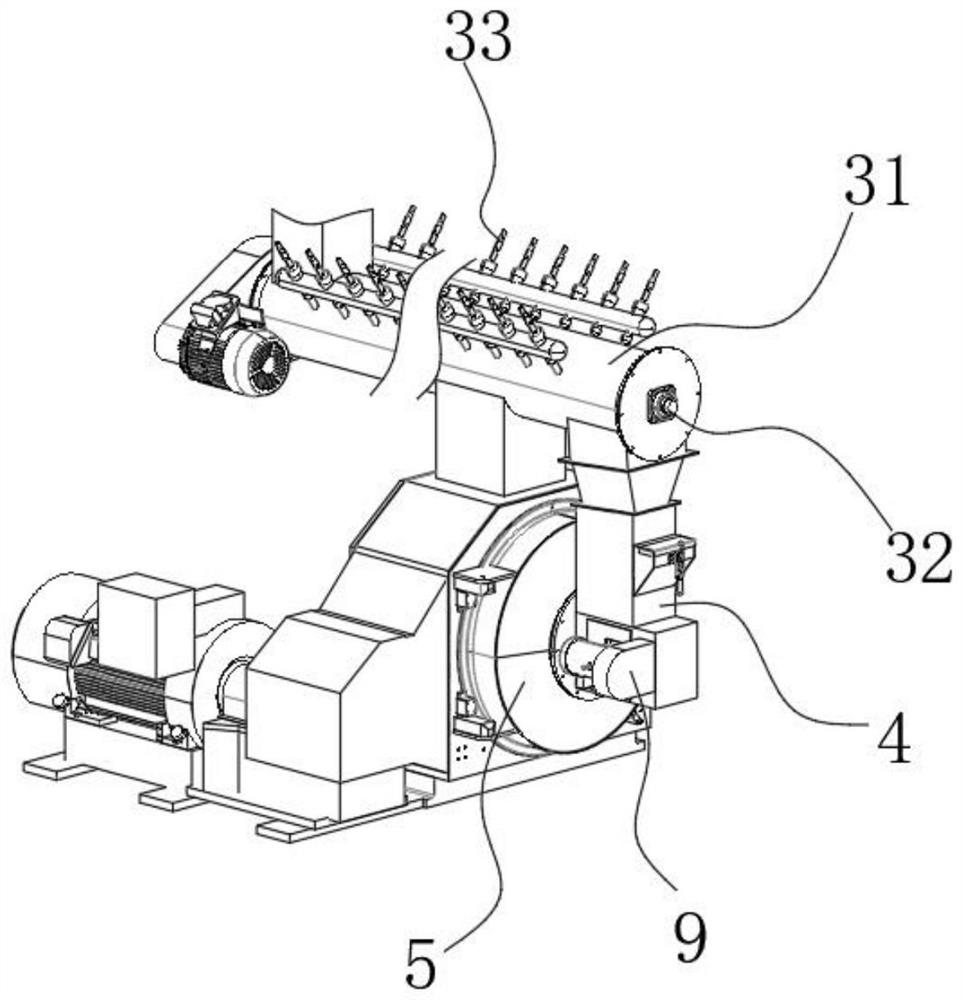

[0038] see Figure 1~5 , the present invention provides a landfill leachate treatment equipment, comprising:

[0039] Concentration tank 1 is used to receive landfill leachate after secondary precipitation. Secondary precipitation is a pretreatment process for landfill leachate, which includes physical precipitation and chemical precipitation, so that turbidity, CODcr, and ammonia nitrogen can be better The removal effect lays a good foundation for subsequent treatment. In addition, a feed port 11 is provided above the concentration tank 1 for receiving landfill leachate and activated sludge powder, and an aeration system can also be set in the concentration tank 1 And the rotation is provided with a scraper 13, and the scraper 13 is driven and rotated by an external motor device. The motor device here includes a motor and a gearbox. In the early stage of the activated sludge powder input, the external motor device is used to drive the scraper 13 to perform conventional rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com