A water surface waste treatment system for a hydropower station

A water surface garbage and treatment system technology, applied in the direction of waste fuel, fuel, biofuel, etc., can solve the problem that water surface garbage is not easy to deal with, and achieve extensive social value and economic value, extensive use value, and strong targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

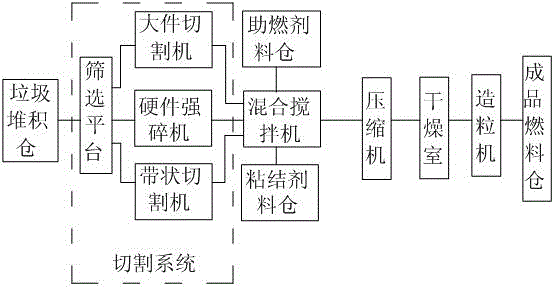

[0016] Such as figure 1 As shown, a water surface garbage treatment system of a hydropower station in the present invention includes a garbage storage bin, a cutting system, a mixing mixer, a compressor, a drying chamber, a granulator, and a finished fuel bin connected in sequence by a conveyor belt, wherein the cutting system includes a Screening platform, the screening platform receives the garbage from the garbage storage bin through the conveyor belt, and the three output ports of the screening platform are respectively connected to the large cutting machine, the hardware strong shredder, and the belt cutting machine, and the large objects in the garbage, such as tree trunks , waste tires and other objects are sent to the large cutting machine, that is, the C series jaw crusher, for cutting into small pieces; the animal remains, corpses, etc. are crushed with a hardware powerful crusher, that is, the PE series jaw crusher, to form pieces Or soft materials that can be proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com