Immersion type hyperfiltration membrane technique operated in the same diaphragm cell and various membrane units

A unit operation, membrane unit technology, applied in ultrafiltration, osmosis/dialysis water/sewage treatment, etc., can solve the problem of unable to restore membrane filtration performance, and achieve the effect of improving equipment utilization, reducing construction costs and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

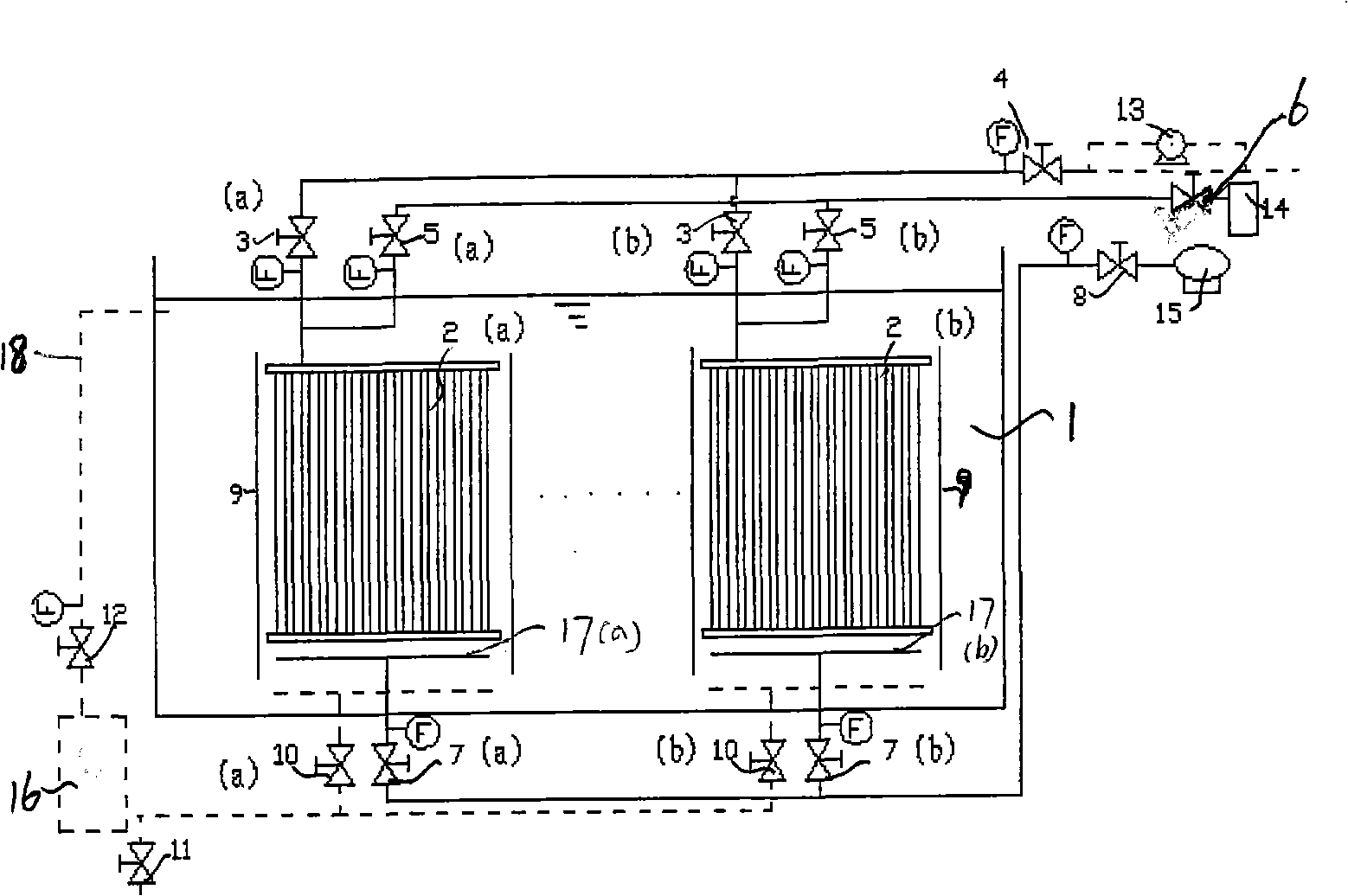

[0023] In the drawings, 1-membrane tank; 2-membrane unit; 3-water production valve; 4-water production main valve; 5-backwash valve; 6-backwash main valve; 7-air wash valve; 8-air wash Main valve; 9-membrane unit isolation device; 10-drainage valve; 11-drainage main valve; 12-return flow regulating valve; 13-water production device (using siphon or water production pump according to design conditions); 14-backwash water tower ( or backwash water pump); 15-blower; 16 concentrated water recovery device; 17 air washing pipe; 18 supernatant return pipe. In addition, corresponding piping, flow meters and pressure gauges are included.

[0024] As shown in the figure, two or more membrane units 2 are installed in the membrane tank 1, and isolation enclosures are arranged between the membrane units. The bottom is lower than the air washing pipe of the air washing device, and the upper part reaches at least the top of the membrane unit. Here, two sets of membrane units 2 (a, b) are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com