A kind of advanced treatment and reuse method of olefin polymerization catalyst production wastewater

A technology for olefin polymerization and wastewater production, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

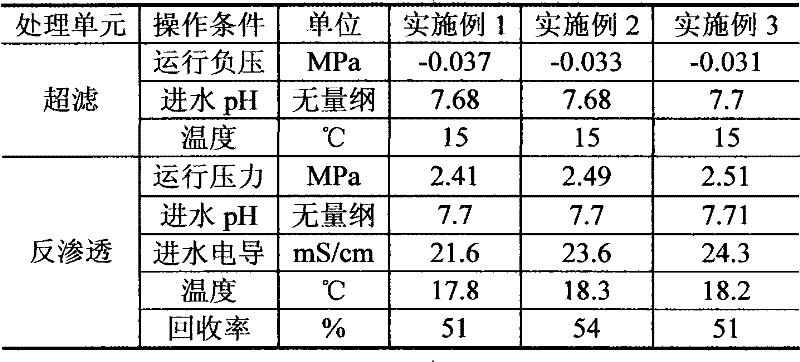

Examples

Embodiment Construction

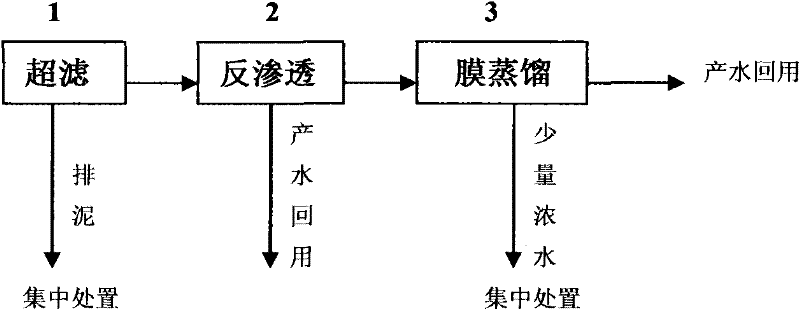

[0035] The specific steps of the present invention will be described below in conjunction with the accompanying drawings of the present invention.

[0036] The waste water is firstly treated by the ultrafiltration unit 1, and then enters the reverse osmosis concentration system 2 for desalination, the reverse osmosis produced water is reused in the production process, and the reverse osmosis concentrated water enters the membrane distillation unit 3 for high concentration after heating, and the membrane distillation produces The water is reused in the production process or as desalinated water, and a small amount of concentrated water remaining from membrane distillation is disposed of in a centralized manner.

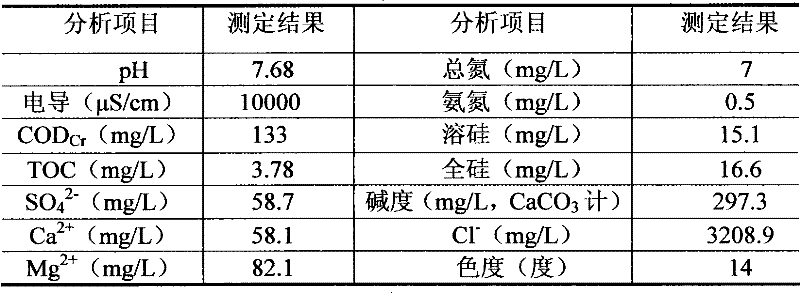

[0037] The typical water quality analysis results of olefin polymerization catalyst production wastewater biochemical effluent are shown in Table 1.

[0038] Table 1 Biochemical effluent quality of olefin polymerization catalyst production wastewater

[0039]

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com