Scale dispersant for water scrubber and application method of scale dispersant

A scale inhibitor and dispersant, water washing tower technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 4g of polyethylene glycol 200, 3g of sodium dodecylbenzenesulfonate, 30g of polyoxyethylene polyoxyethylene ether phosphate (n=3), 30g of dodecyldiethanolamide, and 33g of deionized water into the reactor , stirred at room temperature for 1 hour and then filtered to obtain the scale inhibitor dispersant.

[0022] 1) Determination of dispersion rate: Take 50ml of distilled water and put it into a beaker, add the antiscalant dispersant of the water washing tower, shake it well, put it in a water bath at 60°C, and keep the temperature constant for 30 minutes; weigh about 1g of the scale and put it into the above solution, and stir at a constant temperature 30min. At the same time, a blank water sample comparison experiment was carried out.

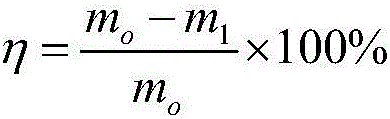

[0023] Calculate the dispersion efficiency of the antiscalant dispersant for the water washing tower according to the following formula.

[0024]

[0025] m0: the amount of initial scale, g

[0026] m1: amount of scale substa...

Embodiment 3

[0032] Add 4g of maleic anhydride, 35g of sorbitan monostearate, 35g of sodium lignin sulfonate, and 26g of deionized water into the reaction kettle, stir at room temperature for 1 hour, and then filter to obtain a scale-inhibiting dispersant. Use this scale-inhibiting dispersant to make In the dispersion experiment, the dispersion efficiency is 62.4%.

Embodiment 4

[0034] Add 5g of maleic anhydride, 40g of polyoxyethylene sorbitan monooleate, 40g of lauryl alcohol, and 15g of deionized water into the reaction kettle, stir at room temperature for 1 hour, and then filter to obtain a scale-inhibiting dispersant. Use this scale-inhibiting dispersant to disperse Experimentally, the dispersion efficiency is 58.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com