Laser anti-fake aluminium-foil and making method

A laser anti-counterfeiting and manufacturing method technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as cracking, damage, inability to meet users, and achieve good high temperature resistance, simple process, good resistance Effects of mildness and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

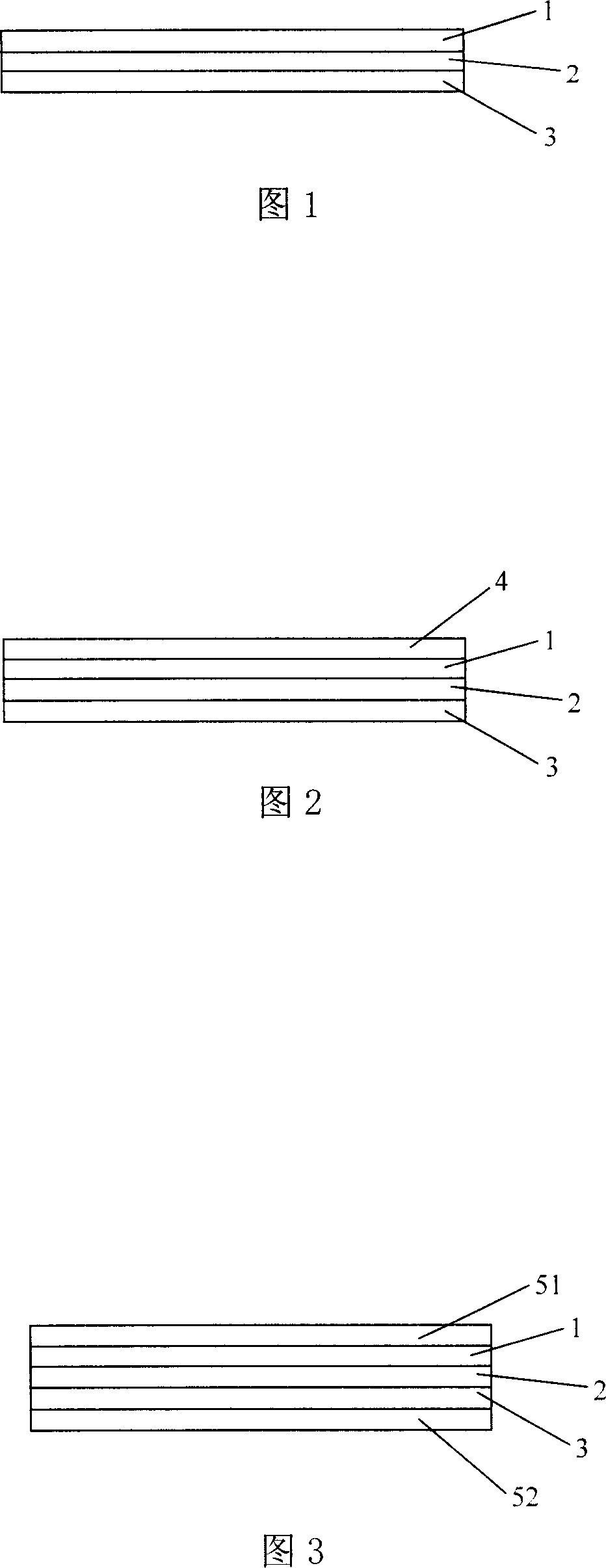

Embodiment 1

[0026] Fig. 1 is a schematic structural view of the laser anti-counterfeiting aluminum foil of the present invention; it includes a visible aluminized layer 1, an adhesive layer 2 and a metal aluminum foil layer 3 stacked in sequence. The visible aluminized layer 1 and the metal aluminum foil layer 3 are combined through the adhesive layer 2. The present invention uses a special adhesive to replace the original self-adhesive, and the bonding effect is better. The viscosity of the adhesive is 140°C The time is the strongest, so after gluing, it should be baked in an oven and then laminated under pressure.

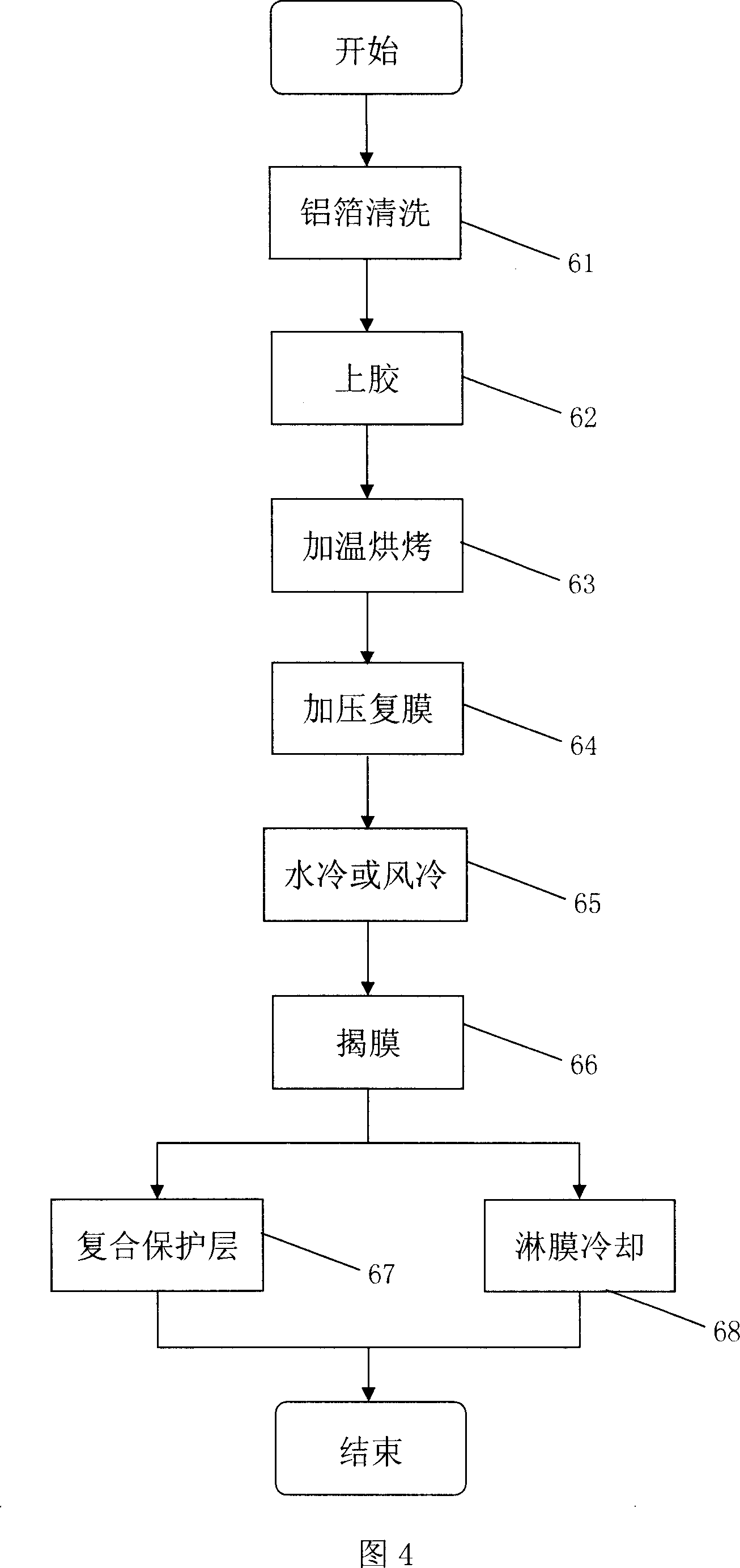

[0027] Fig. 4 is a flow chart of the manufacturing method of the laser anti-counterfeiting aluminum foil of the present invention. The manufacturing method of laser anti-counterfeiting aluminum foil comprises the following steps:

[0028] Aluminum foil cleaning 61: cleaning the surface of metal aluminum foil raw materials;

[0029] Gluing 62: apply glue on the surface of t...

Embodiment 2

[0035] Fig. 2 is a schematic structural view of the laser anti-counterfeiting aluminum foil for building materials of the present invention; in this embodiment, when the processed laser anti-counterfeiting aluminum foil is used in fields such as building materials, a layer of transparent protective layer 4 needs to be compounded outside the visible aluminum coating layer 1. Information content such as patterns or characters on the aluminum layer 1 is protected to prevent scratches or abrasions.

[0036] Correspondingly, in the process steps, after the film 66 is removed, a composite protective layer 67 needs to be added: a transparent protective layer is laminated on top of the visible aluminum plating layer.

Embodiment 3

[0038] Fig. 3 is a schematic structural view of the packaging bag laser anti-counterfeiting aluminum foil of the present invention;

[0039] In this embodiment, when the processed laser anti-counterfeiting aluminum foil is used in packaging bags and other fields, it is necessary to add an outer transparent plastic layer 51 and an inner transparent plastic layer 52 on both sides, and the outer transparent plastic layer 51 is laminated on the visible aluminized layer 1 The inner transparent plastic layer 52 is laminated on the lower side of the metal aluminum foil layer 3 .

[0040] Correspondingly, a composite protective layer 67 needs to be added after peeling off the film 66 in the process steps: at the same time, a transparent plastic layer is composited on the top of the visible aluminum plating layer and the bottom of the metal aluminum foil layer. Or use film cooling 68 after peeling off the film 66: pour the melted plastic liquid onto the two sides of the laser anti-coun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com