Cleaning method of ultrafiltration membrane in sea water desalination by whole membrane technology

A technology of ultrafiltration membrane and full membrane method, which is applied in chemical instruments and methods, seawater treatment, general water supply saving, etc., and can solve the problems of driving cleaning equipment, difficulty in using, and reducing the recovery rate of ultrafiltration water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment is 100m 3 / d's ultrafiltration + nanofiltration full-membrane seawater desalination device, the ultrafiltration membrane adopts 8 sets of hollow fiber membrane modules, and the daily water treatment volume is 240m 3 , ultrafiltration adopts the operation mode of dead-end filtration + concentrated water circulation. One cycle includes five processes: filtration, concentrated water backwash, air wash, concentrated water forward flushing, and raw water forward flushing. The filtration operation time is 20 minutes, and the ultrafiltration output 2660L of water; the ultrafiltration product water enters the closed ultrafiltration product water buffer tank, and the gas in the system is discharged through the top exhaust valve, and at the same time plays a buffer role, so that the ultrafiltration product water and the nanofiltration / reverse osmosis required water phase After matching, the ultrafiltration product water is transported by the low-pressure pump, 50%...

Embodiment 2

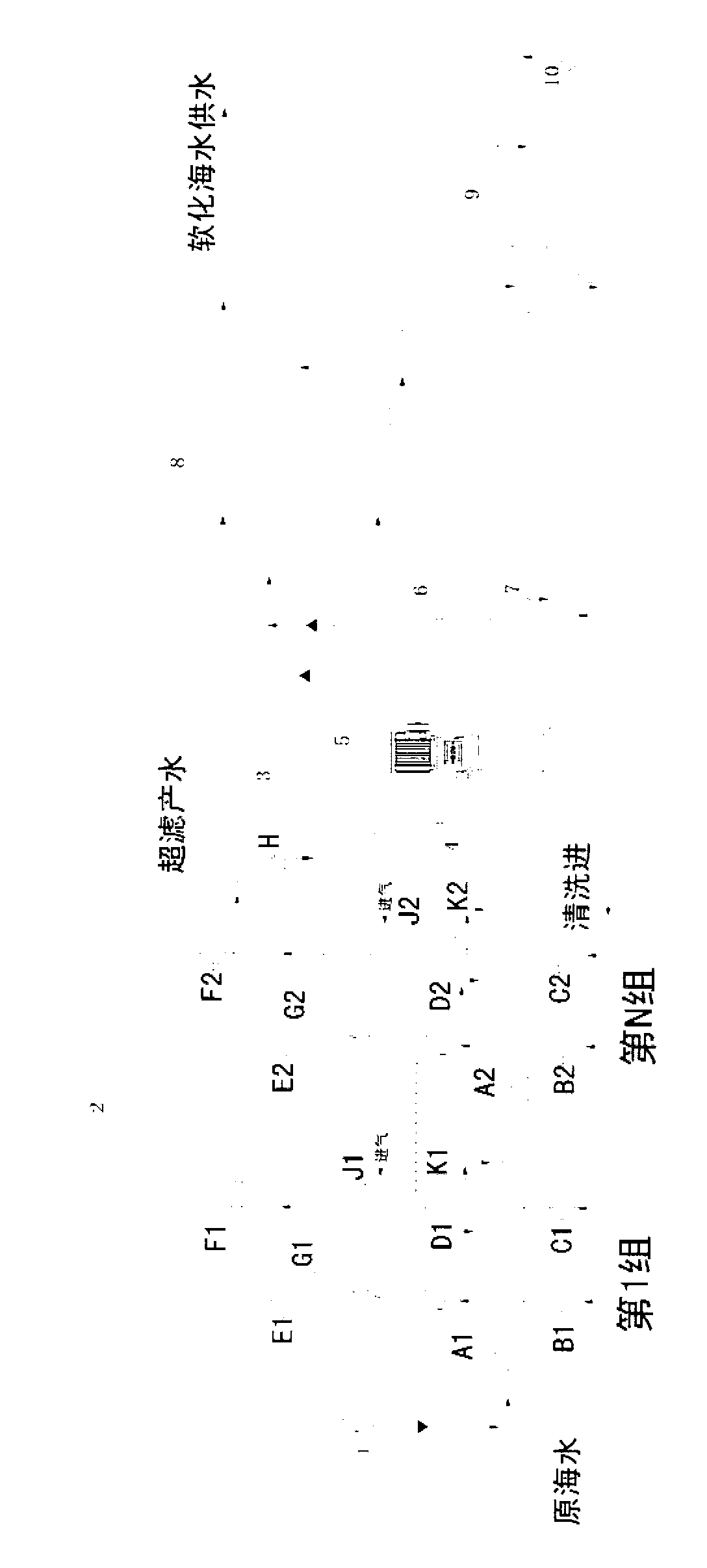

[0024] Such as figure 1 As shown, the ultrafiltration device includes water inlet valves A1, A2, positive flush valves B1, B2, backwash valves C1, C2, lower discharge valves D1, D2, circulation valves E1, E2, water production valves F1, F2, upper discharge valves Valves G1, G2, intake valves J1, J2, replacement valves K1, K2, total circulation pump 1, taking the first group of ultrafiltration as an example, water production process: open A1, E1, F1, close B1, C1, D1, G1, J1 and K1, the first group of water production operation, the water produced by the ultrafiltration device enters the produced water buffer tank 3, and the gas existing in the system is discharged through the top exhaust valve, and then a part of the ultrafiltered produced water is directly input through the intermediate water pump. The high-pressure pump 5 enters the nanofiltration membrane module through pressurization, and the other part enters the energy recovery device 7. After exchanging energy, it enter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com