Method for adjusting out-of-band cut-off width of bandpass filter with multicavity structure

A technology of band-pass filter and adjustment method, applied in the direction of filter, etc., can solve the problem of insufficient cut-off width, etc., and achieve the effect of simple film system and excellent spectral characteristic curve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below according to examples.

[0024] Taking the design of 3.5~4.0μm infrared bandpass filter as an example, the method of widening the cut-off width in the long-wave direction is demonstrated.

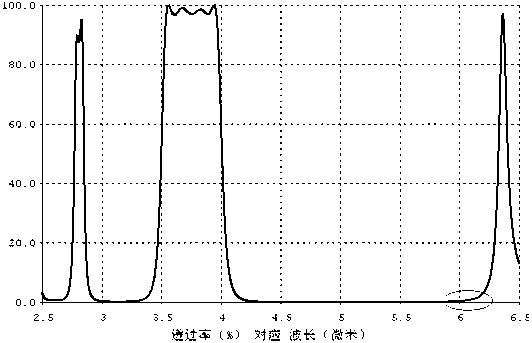

[0025] (1) Select germanium (Ge) as the high refractive index material, silicon monoxide (SiO) as the low refractive index material, adopt 4 half-wave film systems L 2H LHL 2H LHL 2H LHL 2H, the reference wavelength is 3.74μm, and the designed The initial film structure basically meets the requirements of bandwidth width, central wavelength position, and passband edge steepness, and its spectral curve is as follows: figure 2 shown. In the actual application process, the user hopes that the signal with a wavelength of 6 μm can be completely cut off, so it is necessary to further widen the cutoff width on the long wavelength side.

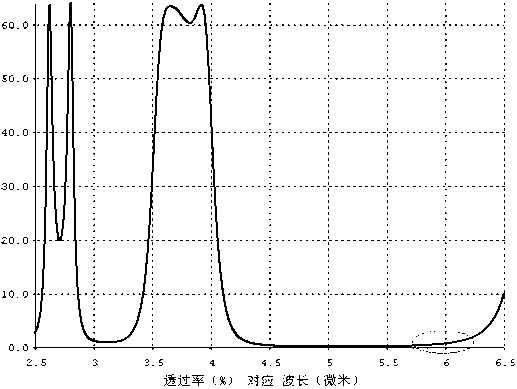

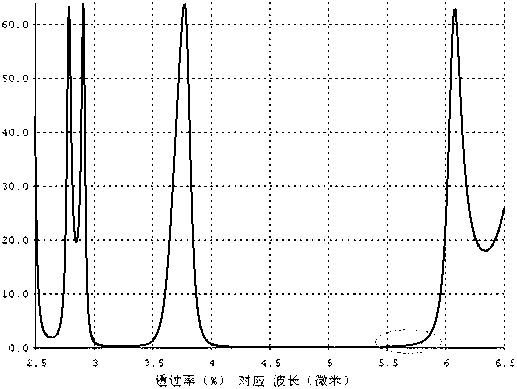

[0026] (2) Using the method of the present invention to widen the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com