Method for hanging membrane in sludge internal circulation biological filter

A technology of biofilter and film-hanging method, which is applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., and can solve the problems of sludge deposition and uneven distribution of biofilm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

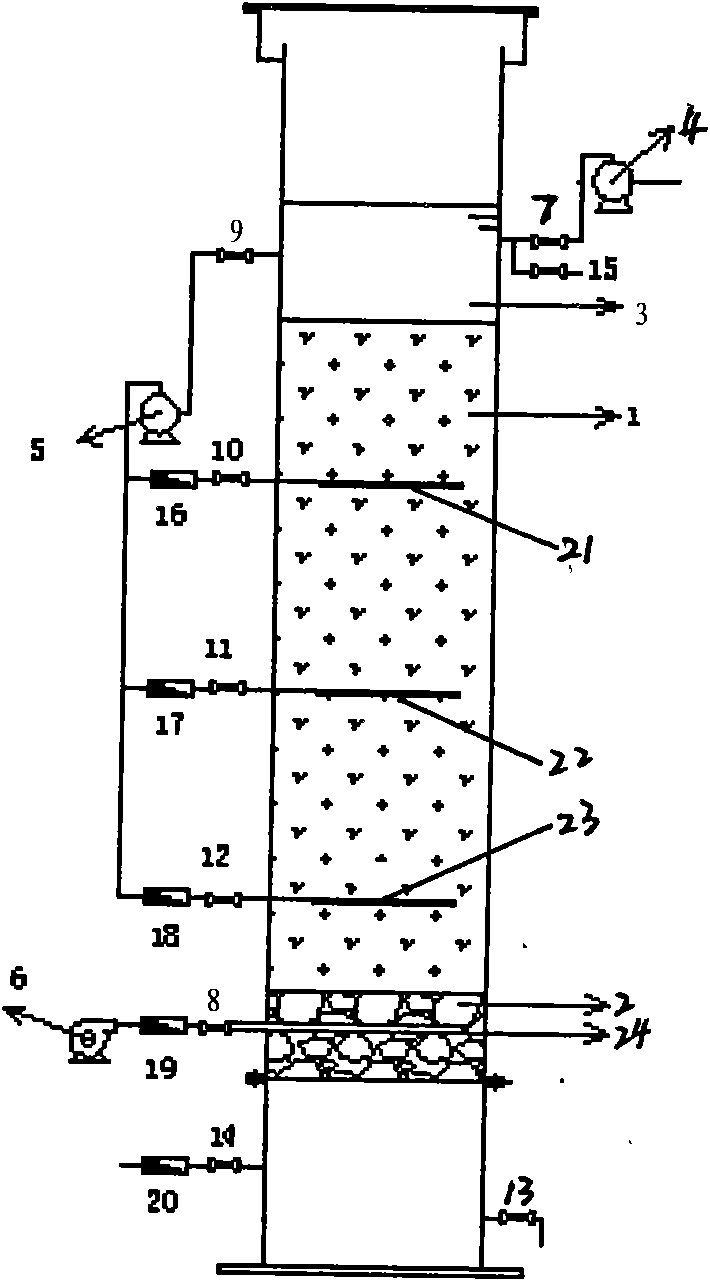

[0018] The test volume is 4.55m 3 The pilot-scale upflow biological aerated filter treats the secondary effluent of urban sewage. Experimental device such as figure 1 As shown, the diameter of the filter column is 1.0m, the height is 6.5m, the filler is ceramsite, the filling height is 4.0m, and there is a 30cm pebble supporting layer underneath. A water outlet pipe is set at a height of 40 cm from the top of the packing layer, and the pipe is connected with a booster pump. The outlet pipeline of the booster pump is divided into 3 branches leading to different filter material height levels respectively, and the water distribution pipes 21, 22, 23 are respectively 1.0, 2.2 and 3.5m away from the top of the packing layer (from top to bottom). Flowmeters and ball valves are installed on the three branch pipes, the reaction temperature is 16.7-26.5°C, and the pH value of the wastewater is 7.0±0.1.

[0019] The activated sludge is taken from the aeration tank of the urban sewage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com