Treatment device and method capable of achieving waste water zero discharge of power plant with large water volume

A technology for power plant waste water and treatment methods, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high investment and operating costs, no economic feasibility, water quality requirements It is not a very high problem, and achieves the effect of reducing investment costs and operating costs, achieving technical feasibility and economic feasibility, and reducing power plant water intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

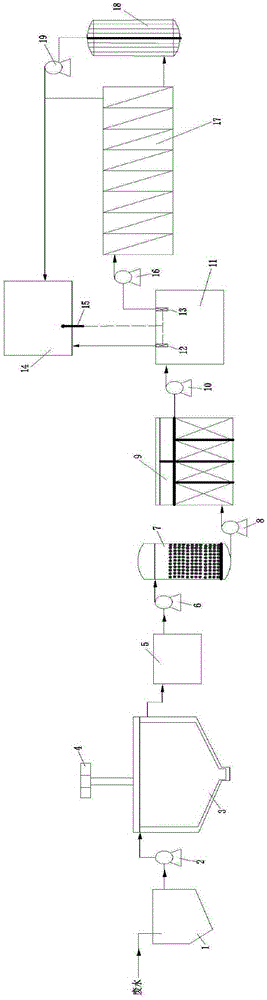

[0047] In this embodiment, the zero-discharge treatment device for large-volume power plant wastewater includes a regulating pool 1, a lift pump 2, a mechanically accelerated clarifier 3, a dosing device 4, a clear water pool 5, a delivery pump 6, a filtering device 7, an ultrafiltration feed Water pump 8, submerged ultrafiltration device 9, ultrafiltration product water pump 10, product water distribution tank 11, first water distribution device 12, second water distribution device 13, clear water mixing tank 14, TDS online monitoring device 15, booster pump 16. Multi-stage reverse osmosis device 17, crystallization device 18, delivery pump 19.

[0048] The adjustment pool 1 communicates with the mechanical acceleration clarification tank 3 through the lifting pump 2, the mechanical acceleration clarification tank 3 is also connected with the dosing device 4 and the clean water tank 5, and the clean water tank 5 is also connected with the filter device 7 through the delivery p...

Embodiment 2

[0060] This embodiment is similar to Embodiment 1, the difference is that: in this embodiment, the specific implementation process of the zero-discharge treatment method for wastewater from large-volume power plants is as follows:

[0061] S1. Measure the content of active silicon in the waste water, introduce the waste water into the regulating pool, and fully mix it. The total amount of water inflow is 2000m 3 / h, TDS is 5000mg / L, and the hydraulic retention time of the adjustment pool is 4h.

[0062] S2. The uniformly mixed wastewater is introduced into the mechanically accelerated clarifier, and CaO and Na are added to the mechanically accelerated clarifier 2 CO 3 , MgO, AlCl 3 and PAM, controlling Ca 2+ with SO 4 2- The molar ratio is 3, Na 2 CO 3 The dosage of MgO is twice the molar amount of CaO added, and the molar ratio of MgO dosage to active silicon in water is 1.5; AlCl 3 The configuration weight percentage concentration of solution is 15%, AlCl 3 The dosa...

Embodiment 3

[0070] This embodiment is similar to Embodiment 1 and / or 2, the difference is that: in this embodiment, the specific implementation process of the zero discharge treatment method for large-volume power plant wastewater is as follows:

[0071] S1. Measure the content of active silicon in the waste water, introduce the waste water into the regulating pool, and fully mix it. The total amount of water inflow is 1500m 3 / h, TDS is 3000mg / L, and the hydraulic retention time of the adjustment pool is 1h.

[0072] S2. The uniformly mixed wastewater is introduced into the mechanically accelerated clarifier, and CaO and Na are added to the mechanically accelerated clarifier 2 CO 3 , MgO, AlCl 3 and PAM, controlling Ca 2+ with SO 4 2- The molar ratio is 1.5, Na 2 CO 3 The dosage of MgO is 1.5 times of the molar amount of CaO added, and the molar ratio of MgO dosage to active silicon in water is 1.3; AlCl 3 The configuration weight percentage concentration of solution is 5%, AlCl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com