Membrane system for realizing high-power concentration

A technology for concentrating membranes and membrane systems, applied in the field of water pollution treatment, can solve the problems of low concentration ratio of membrane systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

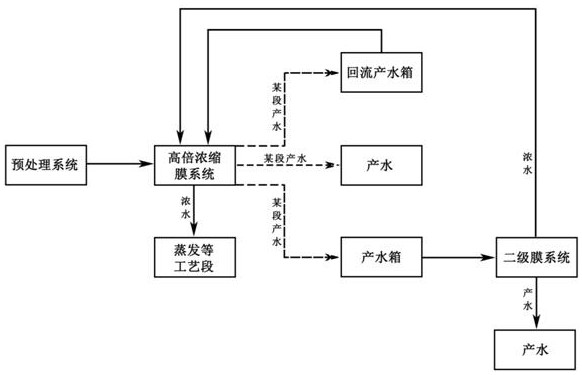

[0035] attached figure 1 It is a flowchart of the present invention. Including the pretreatment system, the pretreatment system treats the raw water through chemical, physical, biochemical and other methods to reduce the alkalinity, hardness and turbidity of the raw water so that it can meet the requirements of entering the membrane system.

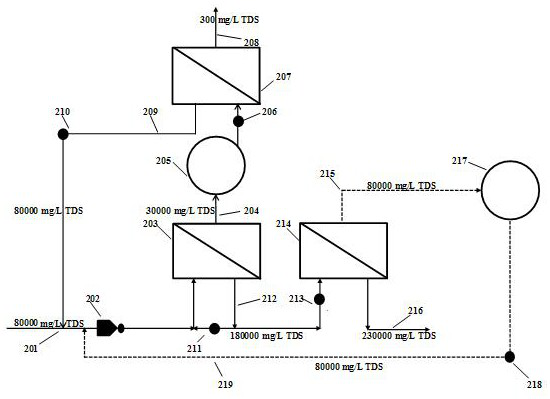

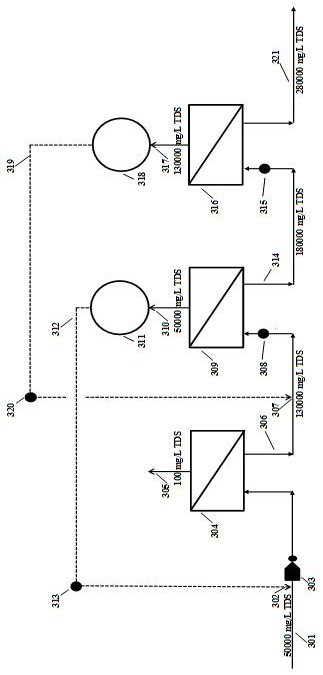

[0036] The high-concentration membrane system can be designed in a multi-stage manner according to the water quality and quantity and specific conditions, and the multi-stage design method can be applied to different water inflow situations. The concentrated water of each section enters the next section through the pipeline, and the water quality and water quantity balance can be realized by setting booster pumps and circulating pumps between the sections, so as to meet the requirements of the inlet water flow and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com