Concentration equipment

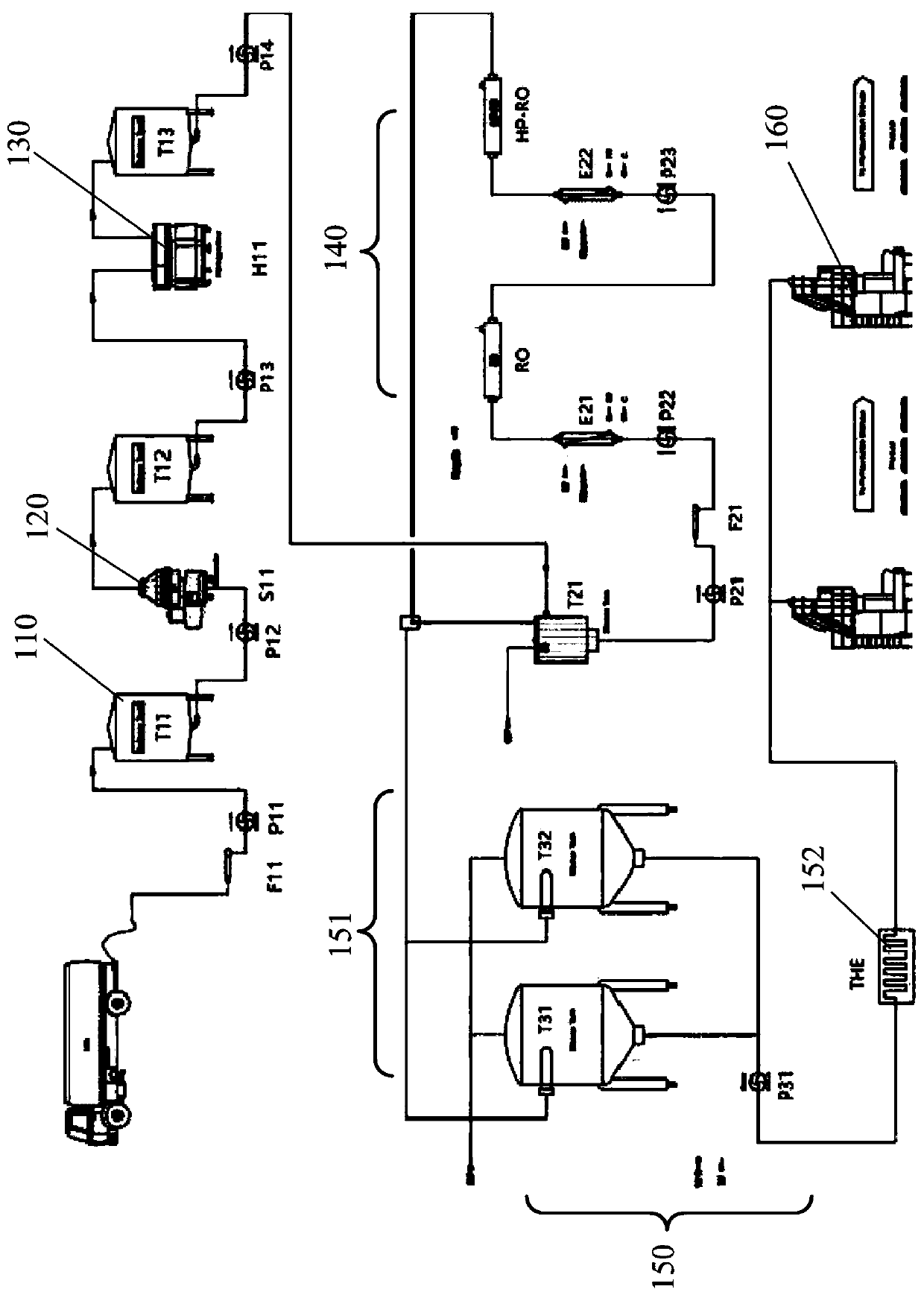

A kind of equipment, reverse osmosis concentration technology, applied in the field of material liquid concentration equipment, can solve the problems of low concentration ratio, high energy consumption, unsatisfactory, etc., to balance the imbalance between seasons and production areas, save preservation costs, and increase the effect of preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] 1) After the raw milk arrives at the factory, the physical and chemical index test is carried out. TS 12.33%, fat 3.2%, and protein 3.1%. The raw milk that meets the requirements is filtered to remove physical impurities. Among them, the pore size of the primary filter is 1.00mm, and the pore size of the secondary filter is 0.50mm. mm.

[0145] 2) After the raw milk is temporarily stored, it is sterilized and separated, and then the raw milk is cooled to 7 degrees Celsius and stored.

[0146] 3) Raw milk enters the homogenizer for cold homogenization, the temperature is 13 degrees Celsius, and the two-stage pressure is 170bar in total, of which, the pressure of the first-stage homogenization is 120bar, and the pressure of the second-stage homogenization is 50bar, and then it enters the sterilization separator for decontamination. spores, the separation rate of spores is greater than 95%, and the total solid content in the obtained raw milk is 12.35%.

[0147] 4) Raw mi...

Embodiment 2

[0154] 1) After the raw milk arrives at the factory, the physical and chemical indicators are tested, TS 13.1%, fat 2.9%, protein 3.2%, and the raw milk that meets the requirements is filtered to remove physical impurities. Among them, the pore size of the primary filter is 1.00mm, and the pore size of the secondary filter is 0.50mm mm.

[0155] 2) After the raw milk is temporarily stored, it is sterilized and separated, and then the raw milk is cooled to 7 degrees Celsius and stored.

[0156] 3) Raw milk enters the homogenizer for cold homogenization, the temperature is 13 degrees Celsius, and the two-stage pressure is 170bar in total, of which, the pressure of the first-stage homogenization is 120bar, and the pressure of the second-stage homogenization is 50bar, and then it enters the sterilization separator for decontamination. spores, the separation rate of spores is greater than 95%, and the total solid content in the obtained raw milk is 12.35%.

[0157] 4) Raw milk ent...

Embodiment 3

[0164] 1) After the raw milk arrives at the factory, the physical and chemical index test is carried out. TS 12.7%, fat 3.1%, and protein 3.3%. The raw milk that meets the requirements is filtered to remove physical impurities. Among them, the pore size of the primary filter is 1.00mm, and the pore size of the secondary filter is 0.50mm. mm.

[0165] 2) After the raw milk is temporarily stored, it is sterilized and separated, and then the raw milk is cooled to 7 degrees Celsius and stored.

[0166] 3) Raw milk enters the homogenizer for cold homogenization, the temperature is 13 degrees Celsius, and the two-stage pressure is 170bar in total, of which, the pressure of the first-stage homogenization is 120bar, and the pressure of the second-stage homogenization is 50bar, and then it enters the sterilization separator for decontamination. spores, the separation rate of spores is greater than 95%, and the total solid content in the obtained raw milk is 12.35%.

[0167] 4) Raw mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com