High salt wastewater softening and concentrating device and method

A high-salt wastewater and concentration device technology, which is applied in chemical instruments and methods, descaling and water softening, multi-stage water/sewage treatment, etc., can solve the problems of high price and softener waste, and reduce the input volume and cost , reduce the dosage and cost, and reduce the effect of wastewater flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

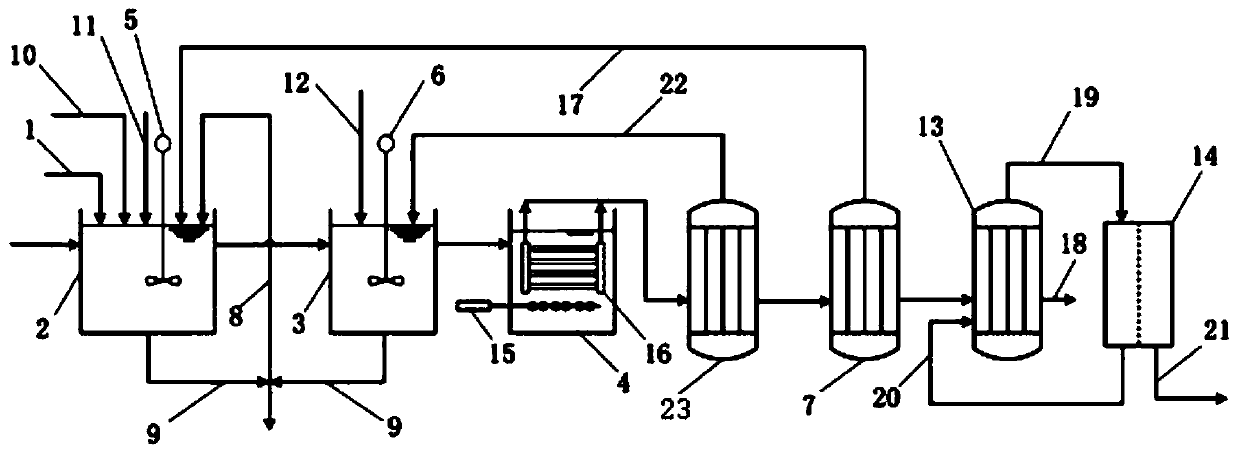

[0036] Such as figure 1 As shown, what described in embodiment 1 of the present invention is a kind of high-salt wastewater softening and concentrating device, and this device comprises:

[0037] The coagulation tank 3 is connected to the softening tank 2 at its inlet, and the outlet of the coagulation tank 3 is connected to the inlet of the microfiltration system 4;

[0038] Ultrafiltration system 23, its inlet port is connected with the outlet port of microfiltration system 4, and the outlet port of ultrafiltration system 23 is connected with nanofiltration system 7 inlet ports;

[0039] Reverse osmosis system 13, its inlet end is connected with the outlet end of nanofiltration system 7, and the outlet end of reverse osmosis system 13 is provided with reverse osmosis water production pipeline 18 and reverse osmosis concentrated water pipeline 19;

[0040] The inlet of the electrodialysis system 14 is connected to the reverse osmosis system 13 through the reverse osmosis con...

Embodiment 2

[0053] What described in embodiment 2 of the present invention is a kind of high-salt wastewater softening and concentrating method, this method comprises:

[0054] Step 1. Transport the high-salt wastewater to the softening pool 2, and add medicine A, medicine B and medicine to the softening pool 2 through the first dosing pipeline 1, the second dosing pipeline 10 and the third dosing pipeline 11 respectively C, Ca in high-salt wastewater 2+ The reaction with the agent B is precipitated and separated, and the sediment is discharged through the mud discharge pipe 9, and the softened wastewater is obtained in the softening tank 2. The agent A is hydrochloric acid or sodium hydroxide, and the pH value of the wastewater in the softening pool 2 is controlled to be between 6.0-7.5; the agent B is sodium oxalate, and the molar concentration of the oxalate in the wastewater in the softening pool 2 is controlled to be equal to the molar concentration of calcium ions. 1.2-2.0 times; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com