Precast stair mold and precast stair machining process

A stair mold and stair technology, applied in the direction of moulds, manufacturing tools, mold fixtures, etc., can solve the problems affecting the quality of prefabricated stairs, the edge of the stressed prefabricated stairs is broken, etc., to improve the quality of prefabricated stairs and reduce uneven stress , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

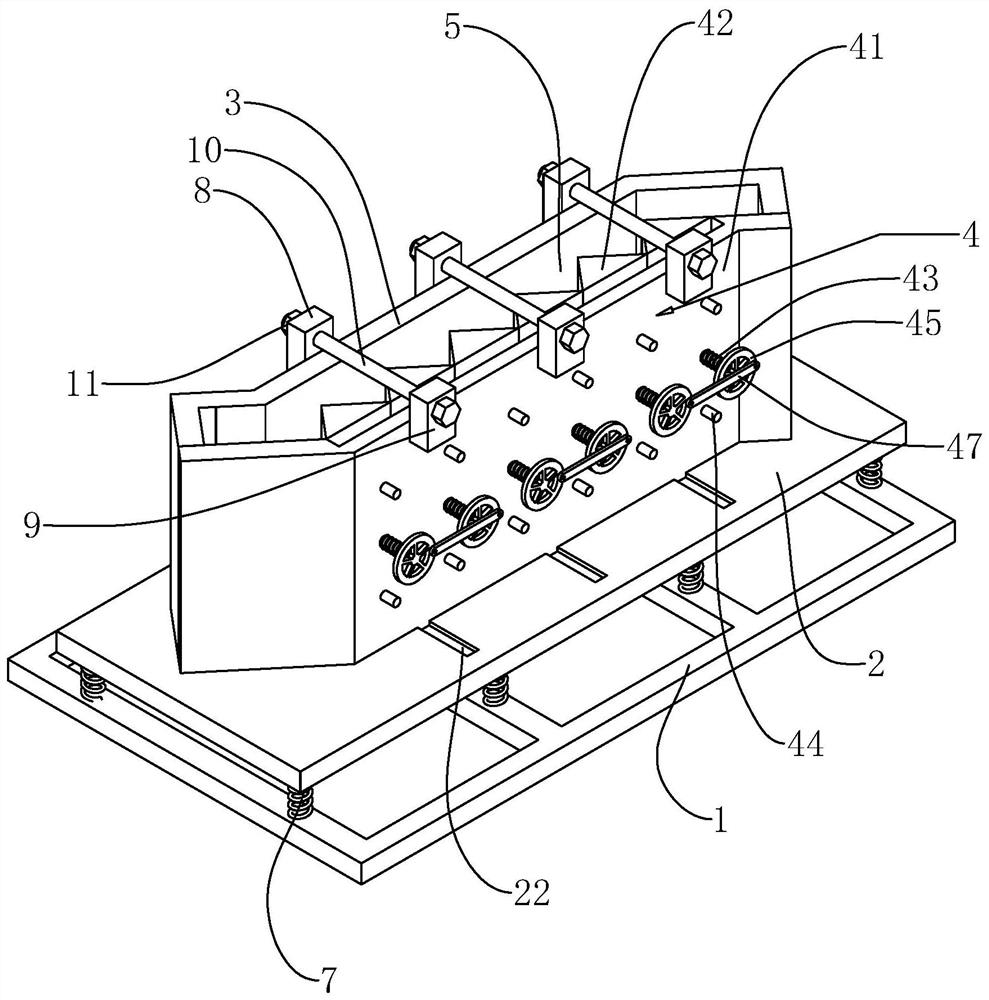

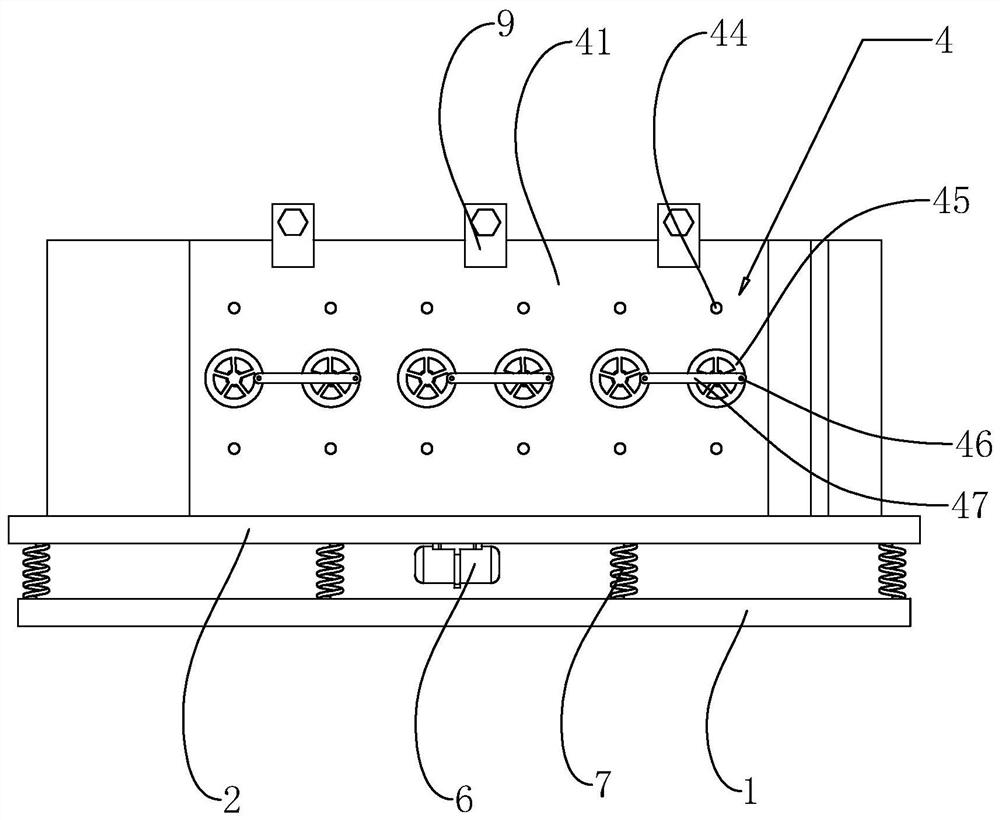

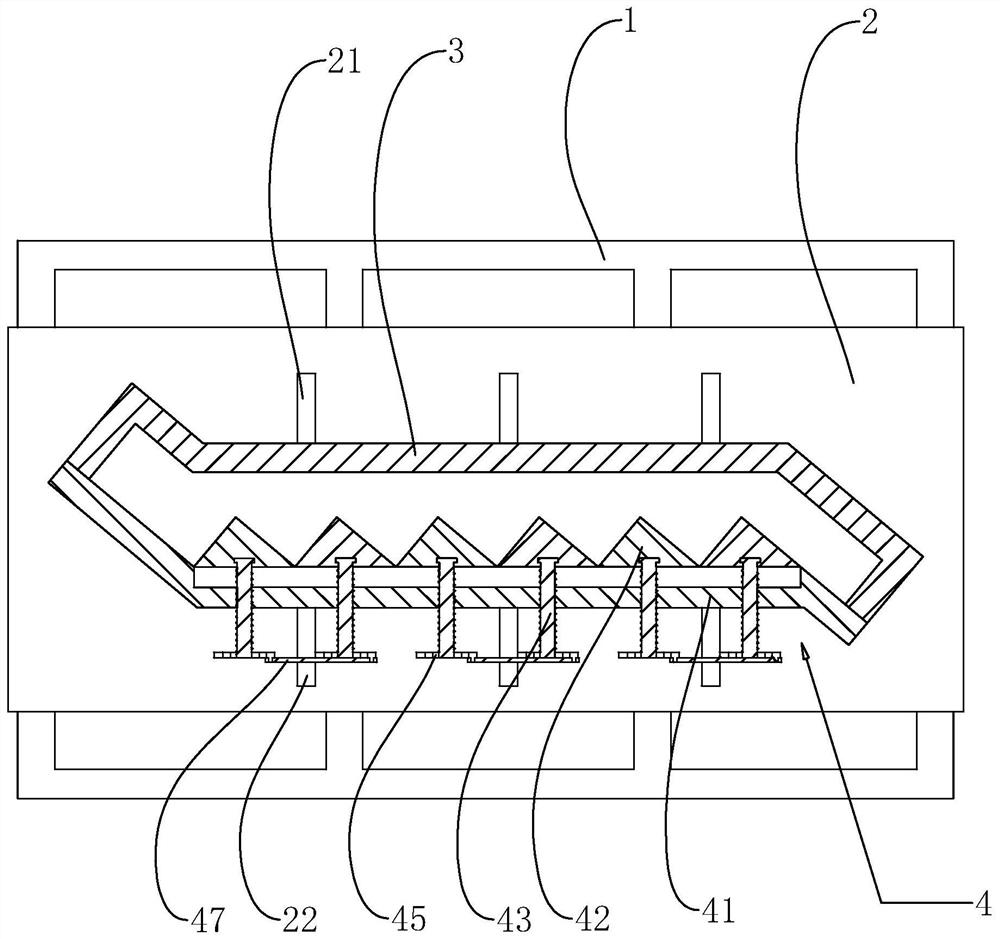

[0040] The application will be described in further detail below in conjunction with all the accompanying drawings.

[0041] The embodiment of the present application discloses a mold for prefabricating stairs.

[0042] refer to figure 1 , a mold for prefabricated stairs, comprising a horizontal support frame 1, a horizontal bottom plate 2 is installed on the support frame 1, a vertical side mold 3 and a vertical staircase mold 4 are slidably connected to the bottom plate 2, the bottom plate 2, the side The mold 3 and the stair mold 4 cooperate with each other to form a casting cavity 5 , which is in the shape of a prefabricated staircase and communicates with the outside world through the upper end of the casting cavity 5 . The operator pours concrete into the pouring cavity 5, plasticizes the concrete through the shape of the pouring cavity 5, and completes the forming process of the prefabricated staircase.

[0043] refer to figure 1 and figure 2 The end of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com