Garment processing auxiliary equipment facilitating automatic cuff edge sealing

A technology of auxiliary equipment and clothing, applied in the field of clothing, can solve the problems of low speed of closing the bottom plate, large force of closing the bottom edge, low efficiency, etc., and achieve the effect of increasing the degree of automation, reducing the operation steps and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

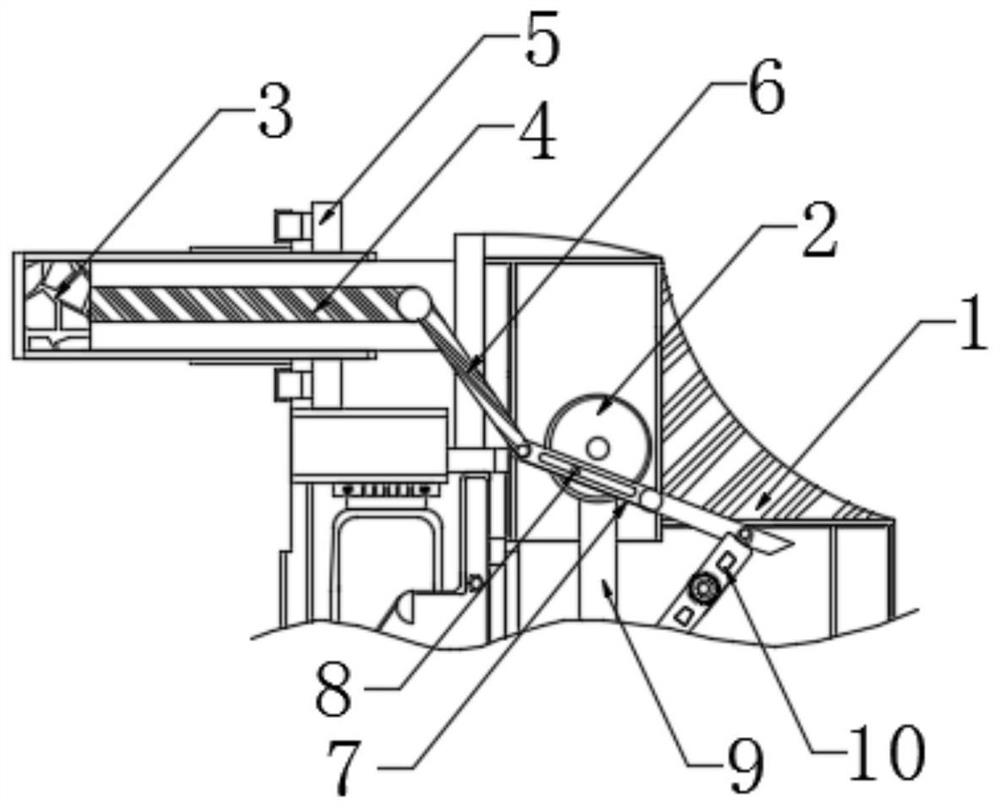

[0027] see figure 2 , a garment processing auxiliary equipment for automatic cuff edge banding, comprising a main body 1 and a disc 2, a pressing block 3 is movably installed on the top of the main body 1, a pulling bar 4 is fixedly connected to the right end of the pressing block 3, and a pulling bar 4 is fixedly installed on the upper end of the pulling bar 4 Magnetic block 5, the right end of magnetic block 5 is movably installed with main shaft part 6, and the bottom end of main shaft part 6 is movably connected with sliding groove 7, and the inner side of sliding groove 7 is movably connected with cylinder 8, and the lower end of cylinder 8 is movably connected with support at the bottom of disc 2. pole 9.

[0028] Further, the slide groove 7 includes a swing block 10, the rear end of the swing block 10 is fixedly installed with an installation frame 11 at the bottom end of the slide groove 7, and a stabilizer 12 is movably connected to the outside of the install frame 1...

Embodiment 2

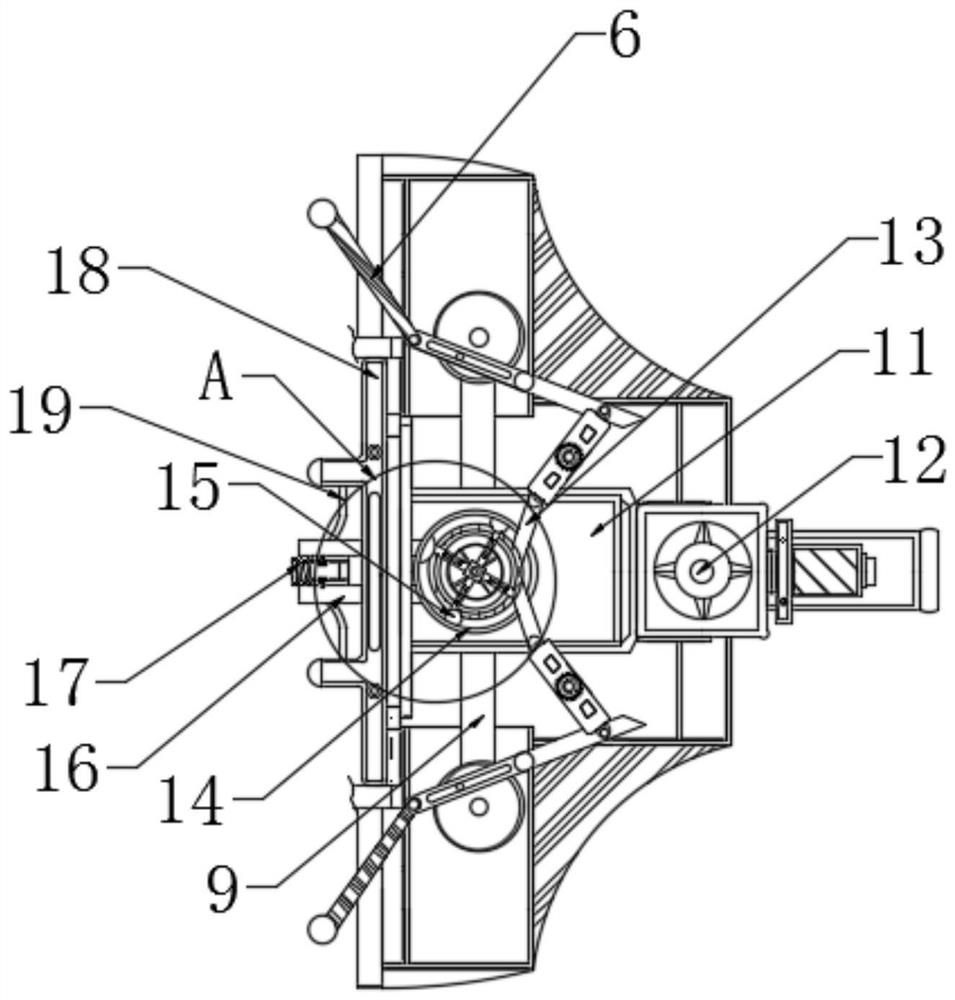

[0031] see image 3 with Figure 4 , a garment processing auxiliary equipment for automatic cuff edge banding, comprising a main body 1 and a disc 2, a pressing block 3 is movably installed on the top of the main body 1, a pulling bar 4 is fixedly connected to the right end of the pressing block 3, and a pulling bar 4 is fixedly installed on the upper end of the pulling bar 4 Magnetic block 5, the right end of magnetic block 5 is movably installed with main shaft part 6, and the bottom end of main shaft part 6 is movably connected with sliding groove 7, and the inner side of sliding groove 7 is movably connected with cylinder 8, and the lower end of cylinder 8 is movably connected with support at the bottom of disc 2. pole 9.

[0032] Further, it also includes a nylon rope 21, the front end of the nylon rope 21 is movably connected with a sliding rod 22 at the top of the center base 20, a limit frame 23 is fixedly installed between the slide rod 22 and the center base 20, and...

Embodiment 3

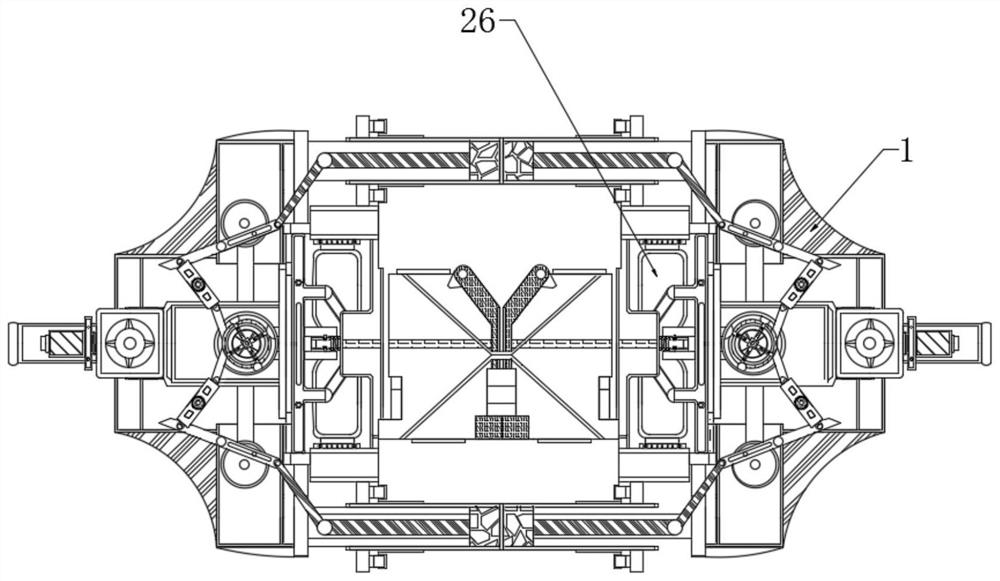

[0037] see Figure 1-5 :

[0038] A garment processing auxiliary device for automatic cuff edge banding, comprising a main body 1 and a disc 2, a pressing block 3 is movably installed on the top of the main body 1, a pulling bar 4 is fixedly connected to the right end of the pressing block 3, and a magnet is fixedly installed on the upper end of the pulling bar 4. Block 5, the right end of the magnetic block 5 is movably installed with a main shaft part 6, the bottom end of the main shaft part 6 is movably connected with a slide groove 7, the inner side of the slide groove 7 is movably connected with a cylinder 8, and the lower end of the cylinder 8 is movably connected with a strut at the bottom of the disc 2 9.

[0039] Further, the slide groove 7 includes a swing block 10, the rear end of the swing block 10 is fixedly installed with an installation frame 11 at the bottom end of the slide groove 7, and a stabilizer 12 is movably connected to the outside of the install frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com