An environmentally friendly high-precision aluminum alloy profile extrusion machine

An aluminum alloy profile, high-precision technology, applied in the field of aluminum alloy processing, can solve the problems of inconvenient aluminum profile good shape and strength, aluminum profile surface pits, poor cooling effect, etc., to achieve continuous and effective filtering effect, reduce stress Uniform, safe and easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

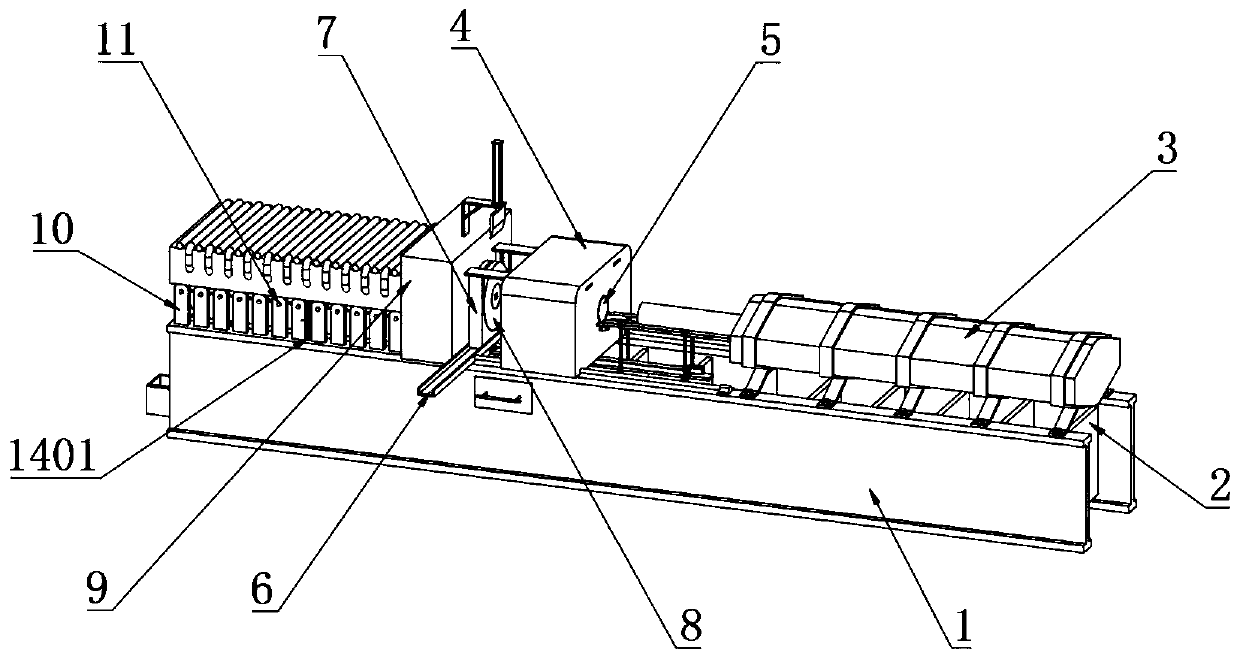

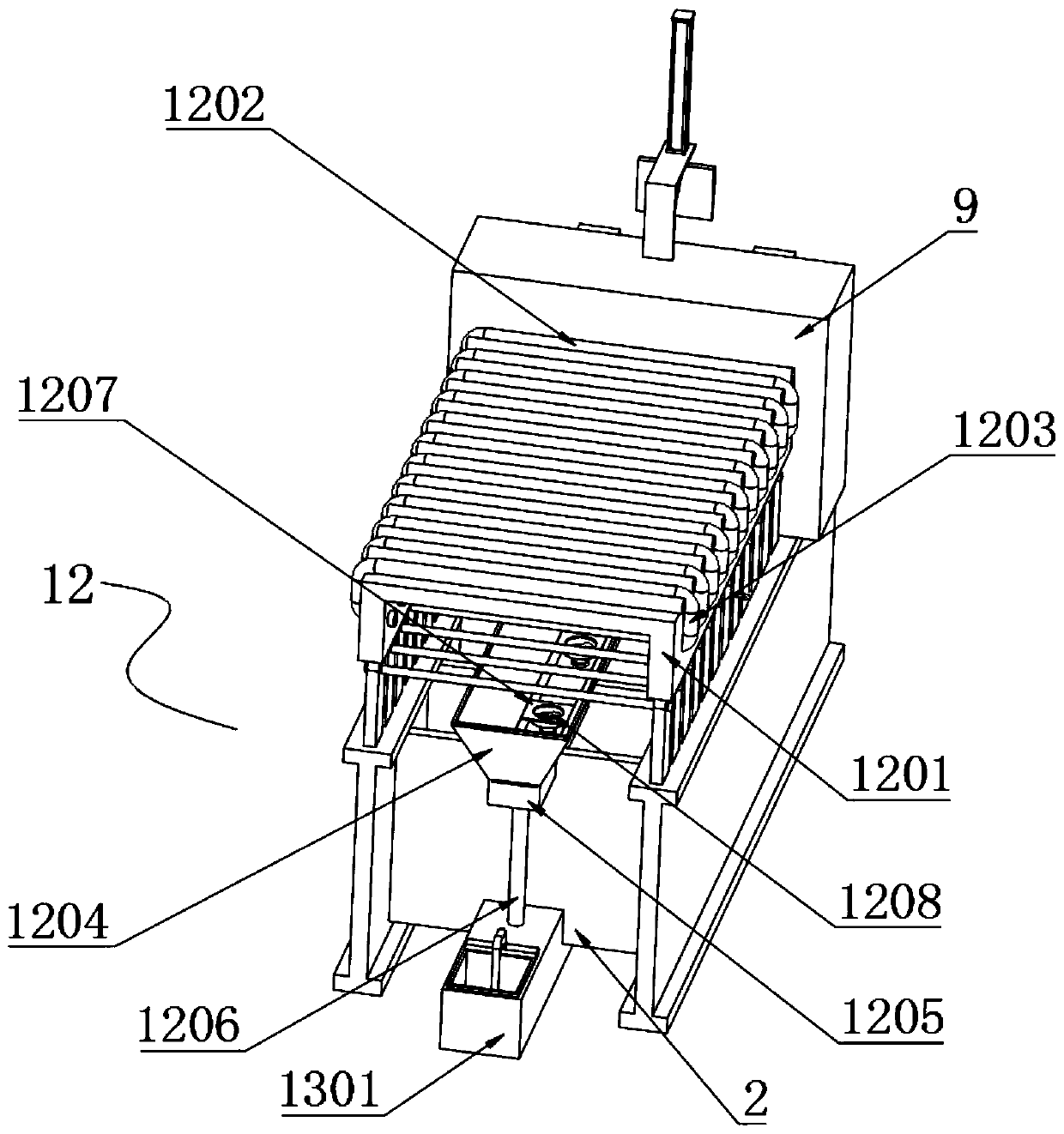

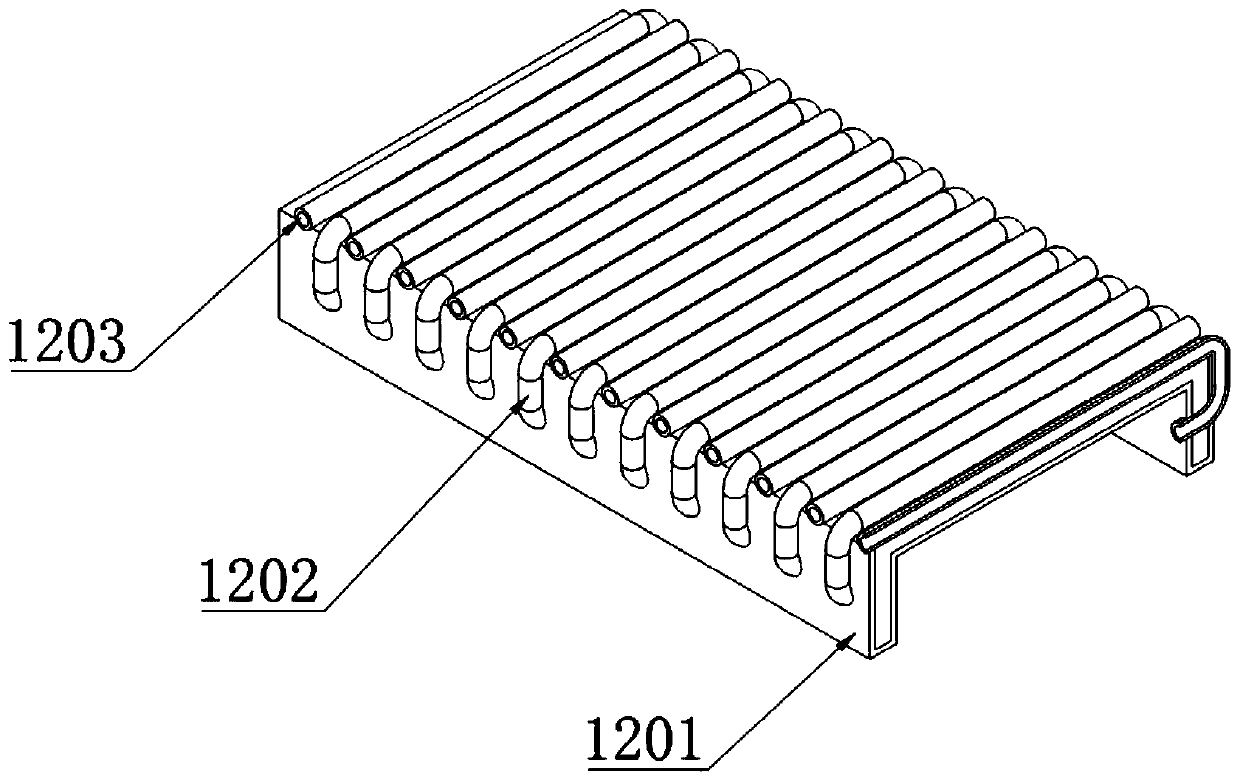

[0048] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, an environmentally friendly high-precision aluminum alloy profile extrusion machine, including a base frame 1, a hydraulic cylinder 3, a material tank 5 and a mold 8, and the hydraulic cylinder 3 is installed on two At the top of the base frame 1, several connecting plates 2 are welded equidistantly between the two base frames 1. A sliding seat 4 is arranged at the top of the base frame 1 corresponding to one side of the hydraulic cylinder 3, and the middle part of the sliding seat 4 corresponds to the hydraulic rod of the hydraulic cylinder 3. The position is embedded with a liner 5, and the top of the base frame 1 is welded with a slideway 6 corresponding to the side of the slide seat 4. The middle part of the slideway 6 is slidably connected to the card holder 7, and the middle part of the card holder 7 is connected to the mold 8. The base frame 1 The top is welded with a blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com