Opto-electric hybrid cable comprising coaxial electric units

一种同轴电单元、光电混合缆的技术,应用在同轴电缆/模拟电缆、电气元件、绝缘电缆等方向,能够解决成本高、外径粗、输电给数量多等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

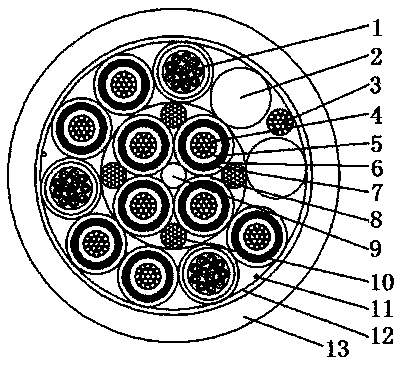

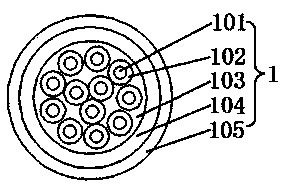

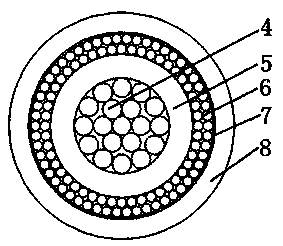

[0026] please see Figure 1 to Figure 3, a photoelectric hybrid cable with a coaxial electrical unit, which is composed of a cable core, a shielding layer 12 covering the cable core, and an outer sheath 13 that is extruded and coated outside the shielding layer. Layer and the outer layer of the cable core located outside the inner layer of the cable core; it is characterized in that the inner layer of the cable core is composed of a central reinforcement 9, four inner coaxial electrical units distributed along the outer edge of the reinforcement and a The filling rope 10 in the outer gap of the adjacent inner layer coaxial electric unit is formed, and each inner layer coaxial electric unit is composed of an inner conductor 4, an insulating layer 5 covering the inner conductor, and an outer layer outside the insulating layer. Conductor 6, insulating tape 7 located outside the outer conductor, and inner sheath 8 coated outside the insulating tape by extrusion molding. On the cr...

Embodiment 2

[0063] please see Figure 4 , and refer to Figure 1 to Figure 3 , the photoelectric hybrid cable with the coaxial electric unit is basically the same as the implementation example 1, the difference is that the solid filling strip can be other multiple; it can also be one; it can also be like Figure 4 Also has a small solid filler strip to round out the outer layer of the cable core.

[0064] Figure 4 The medium and small solid filling strips are located next to the ground wire and in the middle of the two solid filling strips 2 .

[0065] In the present invention, the coaxial power line unit and the optical cable unit are organically twisted into a cable core, the cable core is covered with a metal shielding tape, and a layer of plastic sheath is extruded outside the tape; it is a 4G base station signal transmission system. The processing unit BBU (BasedBandUnit) is ideal for transmitting optical signals and providing power supply cables for the remote radio unit RRU (Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com