Adhesive wrap film

A film and resin composition technology, applied in thin material processing, special packaging objects, applications, etc., can solve the problems of high film adhesion, insufficient adhesion and pull-out properties, etc., and achieve high adhesion and maintenance. The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

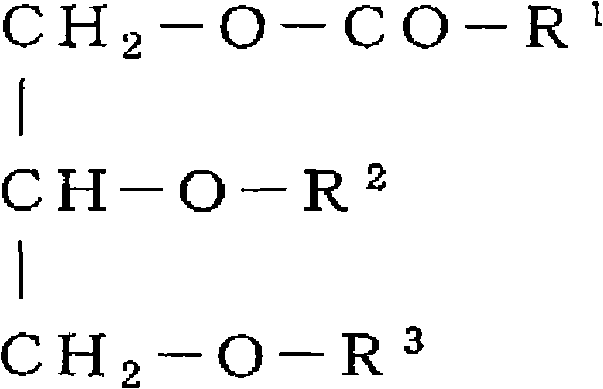

Method used

Image

Examples

Embodiment 1

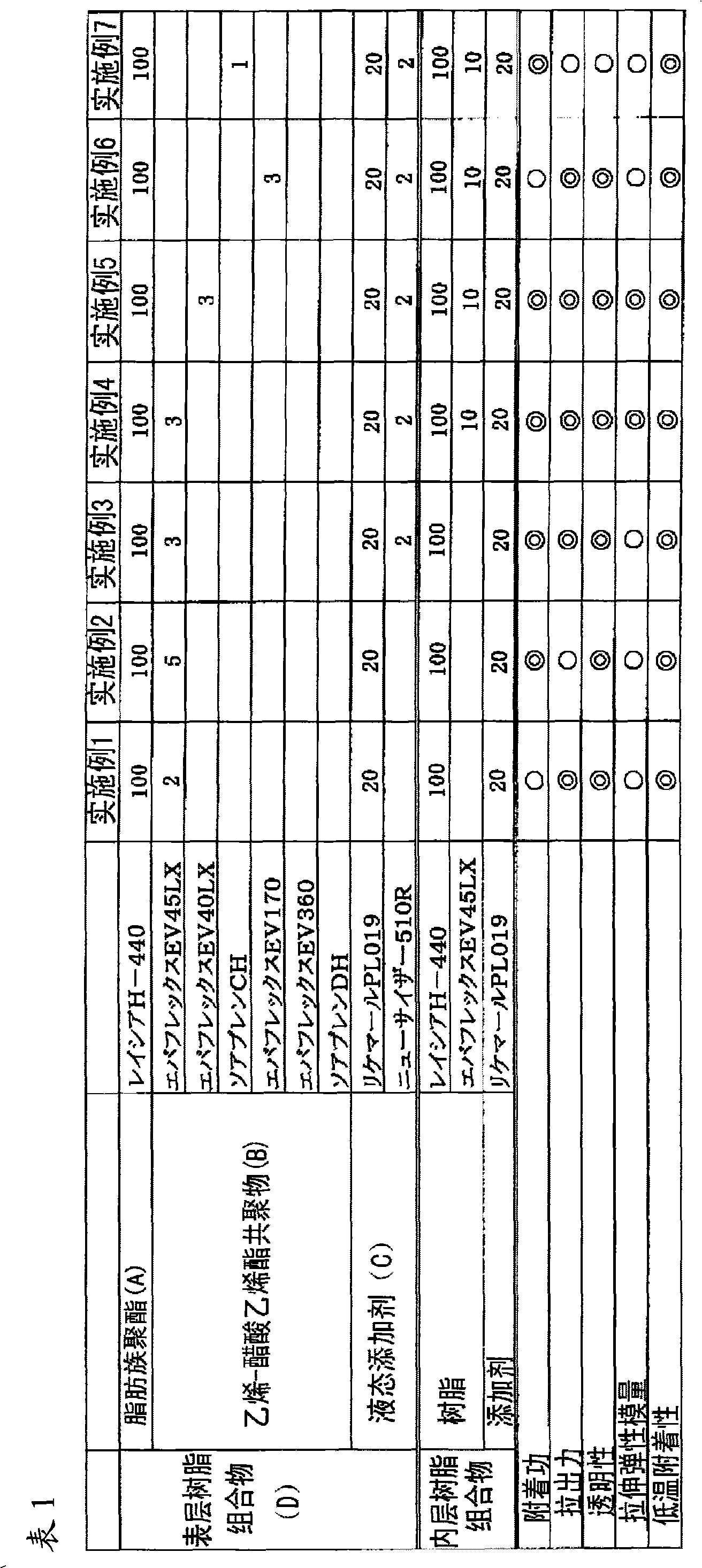

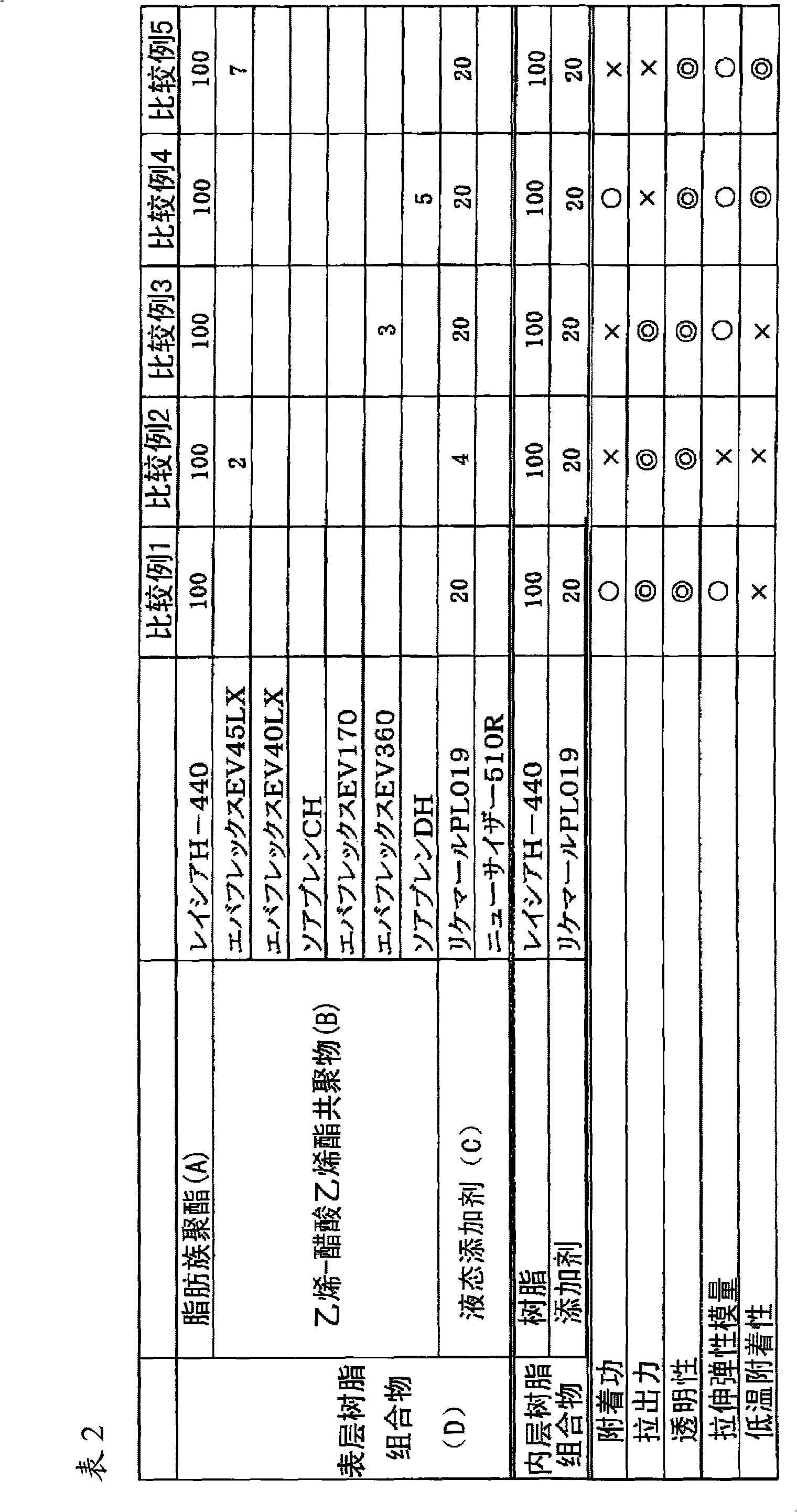

[0063] A mixture of aliphatic polyester resin (A) and ethylene-vinyl acetate copolymer (B) is melt-mixed using a twin-screw extruder, wherein, relative to 100 parts by weight of aliphatic polyester resin (A), ethylene-acetic acid Vinyl ester copolymer (B) is 2 weight parts, and described aliphatic polyester resin (A) is the multipolymer of lactic acid monomer L body and D body, namely D body content is the crystalline polylactic acid resin (melting point : about 150° C.), Leysia H-440 (trade name) manufactured by Mitsui Chemicals Co., Ltd., and the ethylene-vinyl acetate copolymer (B) is Ebaflex EV45LX manufactured by Mitsui DuPont Poly Chemical Co., Ltd. with a vinyl acetate content of 46% by weight. (Product name). At this time, 20 parts by weight of Rikemar PLO19 (trade name, acetylated monoglyceride) manufactured by Riken Bitumin as a liquid additive (C) was injected from the liquid injection part provided in the barrel of the extruder using a quantitative liquid delivery ...

Embodiment 2

[0065] For the resin composition (D) of Example 1, except that the ethylene-vinyl acetate copolymer (B) was changed to 5 parts by weight of Ebaflex EV45LX with a vinyl acetate content of 46% by weight, the same method as in Example 1 was used. In the same way, a film with a thickness of 9 μm was obtained. The work of adhesion, pull-out force, transparency, tensile modulus, and low-temperature adhesion were evaluated for this stretch film. As shown in Table 1, good results were obtained.

Embodiment 3

[0067] For the resin composition (D) of Example 1, except changing the ethylene-vinyl acetate copolymer (B) to 3 parts by weight of Ebaflex EV45LX with a vinyl acetate content of 46% by weight and adding 2 parts by weight of (C) Except for Niu-Saiza-510R (trade name, epoxidized soybean oil) manufactured by NOF Corporation, a film with a thickness of 9 μm was obtained in the same manner as in Example 1. The work of adhesion, pull-out force, transparency, tensile modulus, and low-temperature adhesion were evaluated for this stretch film. As shown in Table 1, good results were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com