High-elastic gray fabric production process

A production process and gray cloth technology, which is applied in the field of high-elastic gray cloth production technology, can solve the problems of gray cloth such as poor elasticity, toughness and strength, difficult to recover, and difficult to repair, and achieve the effect of soft hand feeling, easy rebound, and not easy to be partially damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

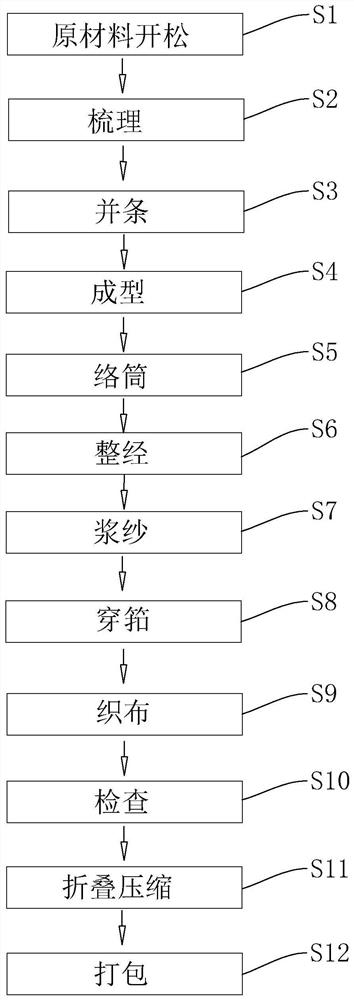

[0044] The following is attached figure 1 The application is described in further detail.

[0045] The embodiment of the present application discloses a high-elastic gray cloth production process, referring to figure 1 , including the following steps:

[0046]S1. Raw material opening and impurity removal: Open the tight cotton bales, polyester yarns, and superfine fiber yarns through a cleaning machine to remove impurities in the raw materials and disperse them evenly. The proportion of cotton threads, polyester yarns, and superfiber yarns It is 5:3:2. Under this ratio, it can not only meet the softness of the subsequent gray cloth, improve the elasticity, toughness and strength of the yarn in the gray cloth, but also save the material of superfine fiber filaments, save costs, and improve the comfort of the gray cloth Spend.

[0047] S2. Carding: Fully disperse the raw materials through the carding machine, and card them evenly along the horizontal direction to form a fluff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com