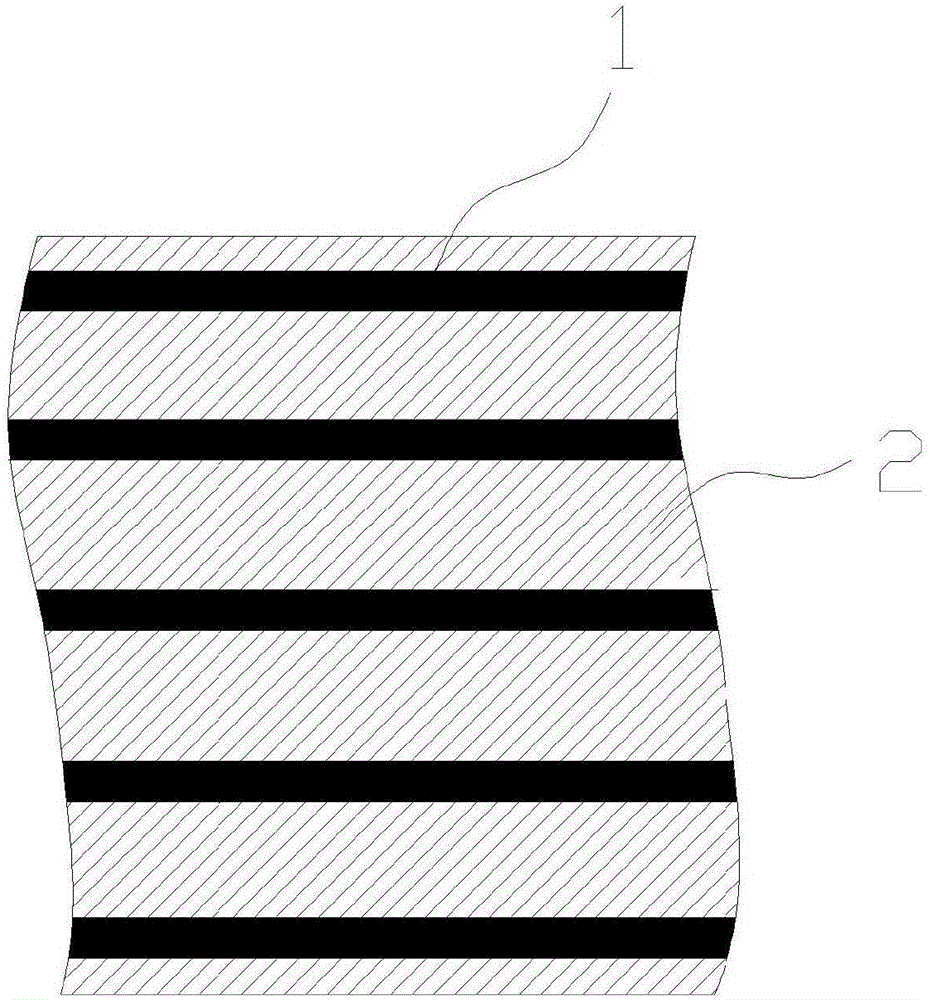

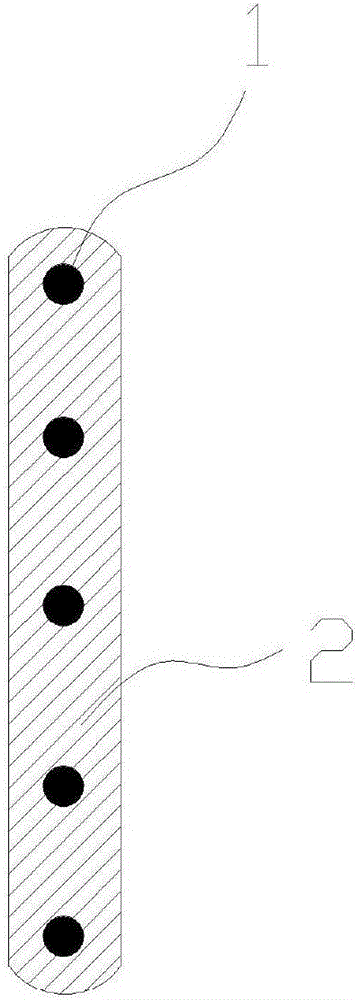

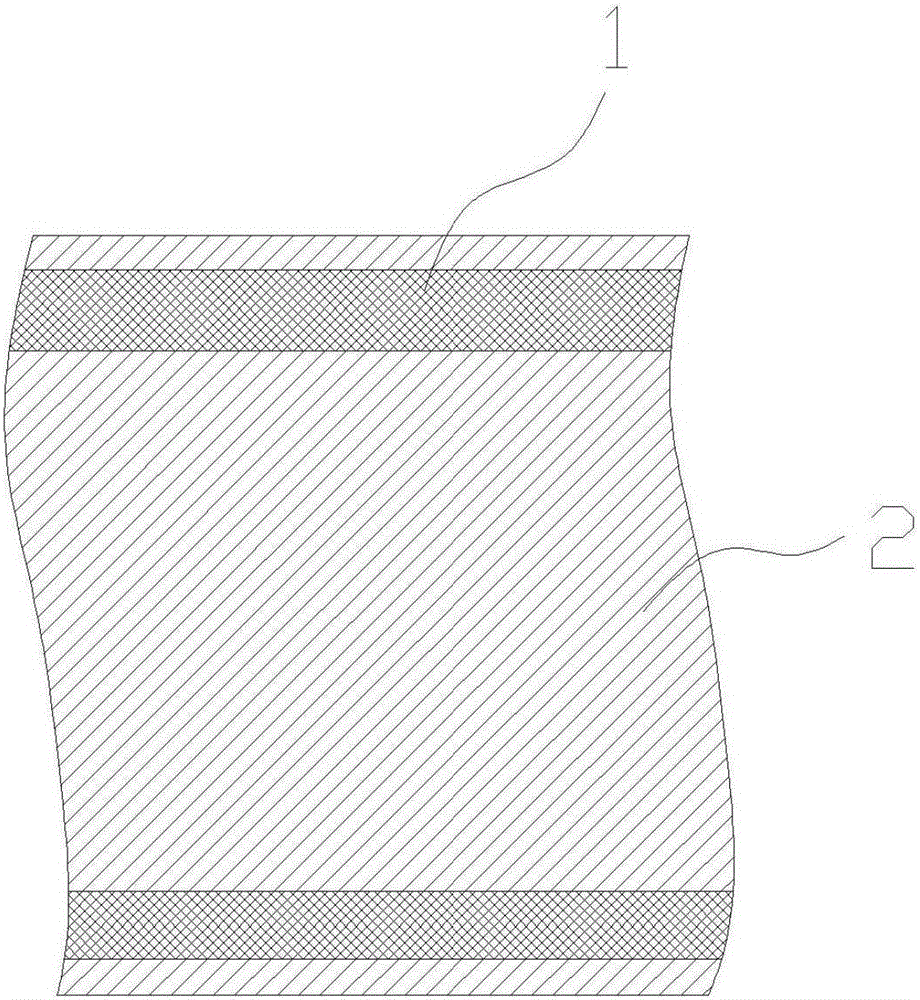

Balance compensation cable for high-speed elevator

A technology for balancing compensation cables and high-speed elevators, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of poor flame retardancy and inflexible bending, achieve good tensile performance, improve safety performance, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw materials in the outer coating layer 2: the components by weight of polyoxyethylene resin, plasticizer, stabilizer, lubricant, flame retardant, accelerator, adhesive, anti-aging agent, reinforcing agent and inorganic filler are :

[0030]

[0031] Get each raw material according to above-mentioned composition and parts by weight thereof, wherein,

[0032] The polyoxyethylene resin is composed of low polymerization degree vinyl chloride resin powder with a polymerization degree of 800-1300 and high polymerization degree vinyl chloride resin powder with a polymerization degree of 2000-3000 in a weight ratio of 1:1.5;

[0033] The plasticizer adopts the mixture of dibutyl fat and dialkyl terephthalate in a weight ratio of 1:4;

[0034] The stabilizer adopts organotin stabilizer;

[0035] The lubricant is a mixture of stearic acid and calcium stearate in a weight ratio of 1:2;

[0036] The flame retardant is a mixture of phosphorus-nitrogen flame retardant and ino...

Embodiment 2

[0043] Raw materials in the outer coating layer 2: the components by weight of polyoxyethylene resin, plasticizer, stabilizer, lubricant, flame retardant, accelerator, adhesive, anti-aging agent, reinforcing agent and inorganic filler are :

[0044]

[0045]

[0046] Get each raw material according to above-mentioned composition and parts by weight thereof, wherein,

[0047]The polyoxyethylene resin is composed of low polymerization degree vinyl chloride resin powder with a polymerization degree of 800-1300 and high polymerization degree vinyl chloride resin powder with a polymerization degree of 2000-3000 in a weight ratio of 1:2;

[0048] The plasticizer adopts the mixture of dibutyl fat and synthetic vegetable oil ester in a weight ratio of 1:4;

[0049] The stabilizer adopts organotin stabilizer;

[0050] The lubricant is a mixture of stearic acid and oxidized paraffin in a weight ratio of 1:1.5;

[0051] The flame retardant is a mixture of phosphorus-nitrogen fla...

Embodiment 3

[0058] Raw materials in the outer coating layer: polyoxyethylene resin, plasticizer, stabilizer, lubricant, flame retardant, accelerator, adhesive, anti-aging agent, reinforcing agent and inorganic filler. The parts by weight of the components are:

[0059]

[0060]

[0061] Get each raw material according to above-mentioned composition and parts by weight thereof, wherein,

[0062] The polyoxyethylene resin is composed of low polymerization degree vinyl chloride resin powder with a polymerization degree of 800-1300 and high polymerization degree vinyl chloride resin powder with a polymerization degree of 2000-3000 in a weight ratio of 1:1;

[0063] The plasticizer adopts the mixture of dialkyl terephthalate and synthetic vegetable oil ester in a weight ratio of 1:1;

[0064] The stabilizer adopts organotin stabilizer;

[0065] The lubricant is a mixture of stearic acid, calcium stearate and barium stearate in a weight ratio of 1:2:1.5;

[0066] The flame retardant is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com