A kind of three-dimensional accumulation body reinforced titanium matrix composite material and its preparation method

A titanium-based composite material and three-dimensional stacking technology, which is applied in the field of three-dimensional stacked reinforced titanium-based composite materials and their preparation, can solve the problems of poor mechanical properties, poor high temperature resistance, and low preparation costs of composite materials, and achieve high damping Capacity, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

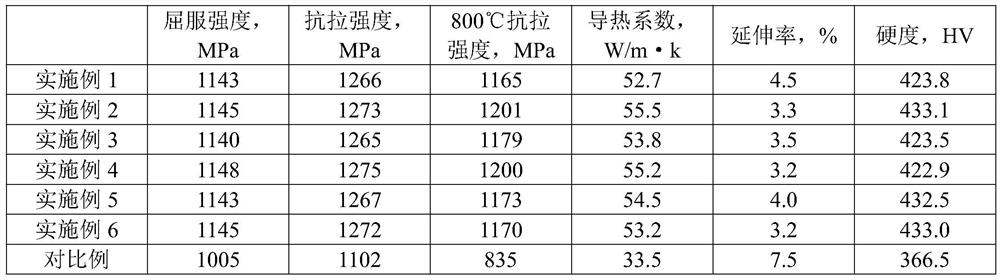

Examples

Embodiment 1

[0025] (1) dispersing 3g graphene nanosheets in ethanol to make concentration is the graphene nanosheet dispersion liquid of 15wt%; With 0.13g sophorolipid and 0.12g two (hydroxyethyl) methyl dodecyl chlorination Dissolve ammonium in a mixture of ethanol and water with a volume ratio of 2:1, mix the dispersion and the mixture, add them to a three-necked flask, stir at 50°C for 1 hour, then cool to room temperature, add 1g of ethyl orthosilicate dropwise, Continue stirring for 3 hours, filter, wash and dry the filtered solid, place the dried powder in a muffle furnace, and calcinate at 500° C. for 3 hours to obtain a graphene / silicon oxide nanotube array composite;

[0026](2) Dissolve 10mL of titanium tetrachloride in 80mL of ethanol, after stirring and mixing, dropwise add a hydrochloric acid solution with a concentration of 15mol / L, continue stirring for 10min, then add 1mL of deionized water, and stir to obtain a sol; The sol and the graphene / silicon oxide nanotube array co...

Embodiment 2

[0029] (1) dispersing 3g graphene nanosheets in ethanol to make concentration is the graphene nanosheet dispersion liquid of 15wt%; With 0.16g sophorolipid and 0.12g two (hydroxyethyl) methyl dodecyl chlorination Dissolve ammonium in a mixture of ethanol and water with a volume ratio of 2:1, mix the dispersion and the mixture, add them to a three-necked flask, stir at 50°C for 1 hour, then cool to room temperature, add 1g of ethyl orthosilicate dropwise, Continue stirring for 5 hours, filter, wash and dry the filtered solid, place the dried powder in a muffle furnace, and calcinate at 500° C. for 3 hours to obtain a graphene / silicon oxide nanotube array composite;

[0030] (2) Dissolve 10mL of titanium tetrachloride in 80mL of ethanol, after stirring and mixing, dropwise add a hydrochloric acid solution with a concentration of 15mol / L, continue stirring for 10min, then add 1mL of deionized water, and stir to obtain a sol; The sol and the graphene / silicon oxide nanotube array c...

Embodiment 3

[0033] (1) dispersing 3g graphene nanosheets in ethanol to make concentration is the graphene nanosheet dispersion liquid of 15wt%; With 0.14g sophorolipid and 0.12g two (hydroxyethyl) methyl dodecyl chlorination Dissolve ammonium in a mixture of ethanol and water with a volume ratio of 2:1, mix the dispersion and the mixture, add them to a three-necked flask, stir at 50°C for 1 hour, then cool to room temperature, add 1g of ethyl orthosilicate dropwise, Continue stirring for 3.5 hours, filter, wash and dry the filtered solid, place the dried powder in a muffle furnace, and calcinate at 500°C for 3 hours to prepare a graphene / silicon oxide nanotube array composite;

[0034] (2) Dissolve 10mL of titanium tetrachloride in 80mL of ethanol, after stirring and mixing, dropwise add a hydrochloric acid solution with a concentration of 15mol / L, continue stirring for 10min, then add 1mL of deionized water, and stir to obtain a sol; The sol and the graphene / silicon oxide nanotube array ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com