Pneumatic tire manufacturing method

A manufacturing method and technology of pneumatic tires, applied in tires, applications, household appliances, etc., can solve problems such as peeling and cracks, and achieve good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10、 comparative example 1

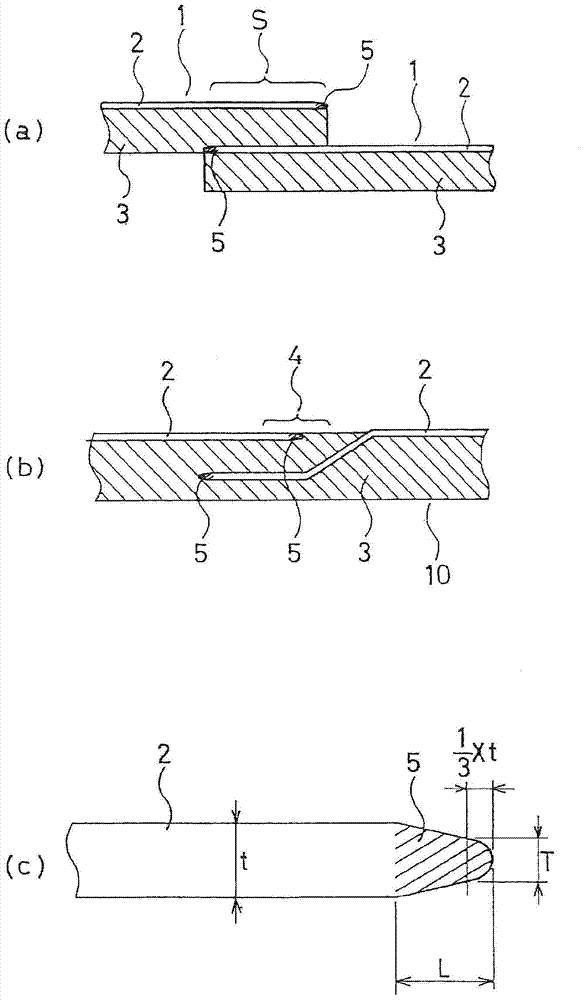

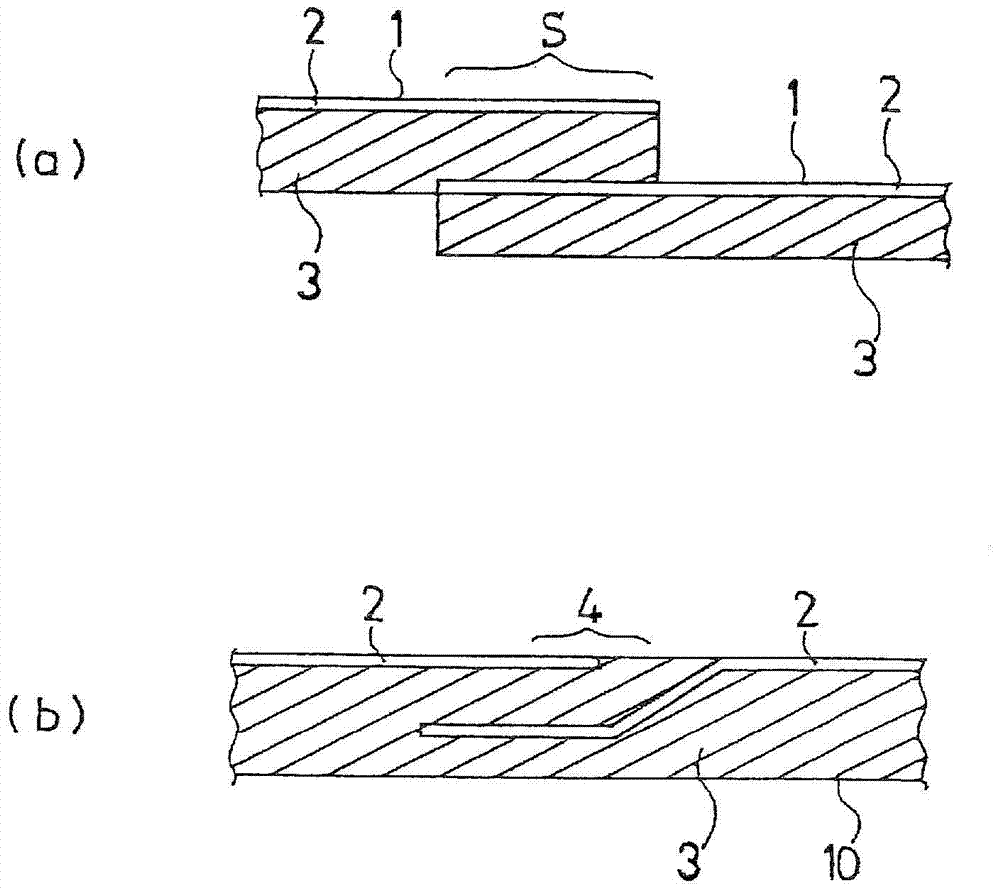

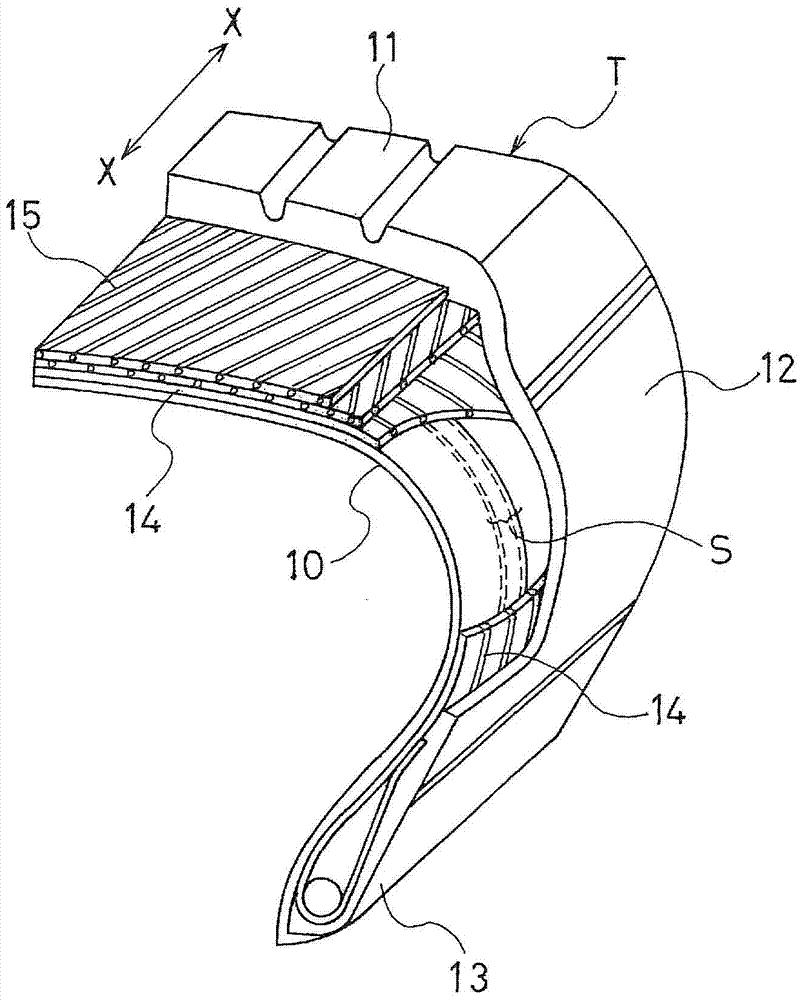

[0076] Hereinafter, the manufacturing method of the pneumatic tire of this invention is demonstrated concretely using an Example etc. FIG.

[0077] As a sheet of the thermoplastic resin composition, as shown in Table 1, a thermoplastic resin composition having a thickness (t) of 0.13 mm and a melting point of 190 mm was prepared by blending N6 / 66 as a thermoplastic resin and BIMS as an elastomer at a ratio of 50 / 50. ℃ sheet.

[0078] On the other hand, as the connecting rubber layer, connecting rubber having a composition as shown in Table 2 and having a thickness of 0.7 mm was prepared.

[0079] [Table 1]

[0080]

parts by mass

BIMSa)

"Exxpro3035" manufactured by ExxonMobil Chemical Co., Ltd.

100

"Yaqianhua No. 3" manufactured by Zhengdong Chemical Industry Co., Ltd.

0.5

industrial stearic acid

0.2

"Zinc Stearate" manufactured by NOF Co., Ltd.

1

N6 / 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com