Water vapor barrier film and method for producing same

一种水蒸气阻隔、制造方法的技术,应用在化学仪器和方法、电气元件、硅化合物等方向,能够解决达不到实用化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] (1) Preparation of lithium-exchanged clay

[0088] Natural purified bentonite (manufactured by Kunipia F Kunimine Industry Co., Ltd.) was fully dried in an oven at a temperature of 110° C. or higher. 300 g of this bentonite was put into a ball mill barrel together with alumina balls. Next, 6 g of a silanizing agent (Syraace S330 manufactured by Chicso Corporation) was added thereto, and the inside of the cylinder was replaced with nitrogen gas, and ball milling was performed for 1 hour to obtain a silanized clay. As a silylating agent, what has an amino group at the terminal is used.

[0089] 24 g of silanized clay was added to 400 mL of a 0.5 N lithium nitrate aqueous solution, and mixed and dispersed by shaking. Vibration dispersion was performed for 2 hours to exchange the interlayer ions of the clay to lithium ions. Next, solid-liquid separation was performed on the dispersion liquid by centrifugation, and the obtained solid was washed with a mixed solution of 28...

Embodiment 2

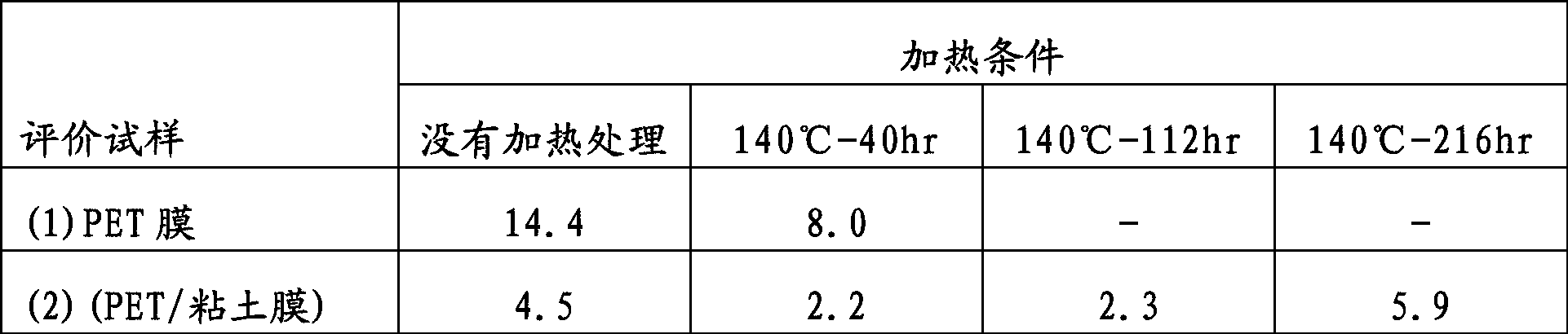

[0104] In this example, the water vapor permeability of the water vapor barrier film was measured using a humidity sensor (manufactured by Lyssy Co., Ltd., trade name: L80-5000 type) for the PET / clay film prepared in Example 1 above. Will use 50cm 2 The atmosphere on the lower side of the space partitioned by the sample film was adjusted to a relative humidity of 100%, and the atmosphere on the upper side was adjusted to a relative humidity of 9.9% or less. Then, by the water vapor permeating the clay film, the time for the relative humidity of the atmosphere on the upper side of the sample film to change from 9.9% to 10.1% is calculated for the water vapor transmission rate (g / m 2 day). The results are shown in Table 2.

[0105] [Table 2]

[0106] Water vapor permeability of products heated at 140°C (g / m 2 day) (humidity sensor)

[0107]

[0108] In the water vapor barrier film that was heat-treated at 140°C for 40 hrs, the method of placing the film was switched from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com