Patents

Literature

41results about How to "Moisture absorption fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

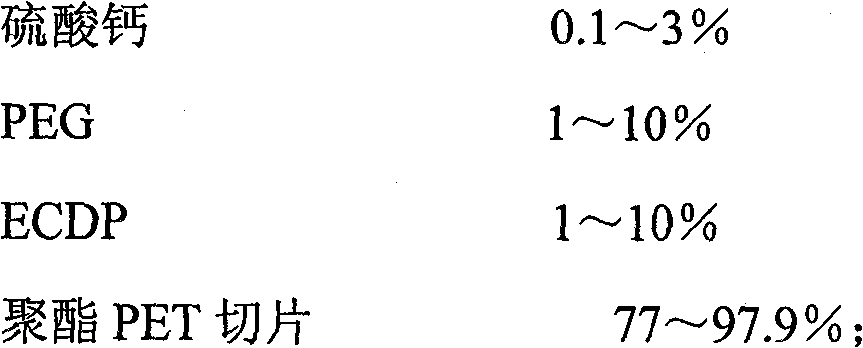

Cotton-simulated terylene short fiber and preparation method thereof

ActiveCN101831727AGuaranteed spinnabilitySimple processHollow filament manufactureFilament manufacturePolyesterState of art

The invention provides a cotton-simulated terylene short fiber. Concave pits are formed on the surface of the cotton-simulated terylene short fiber; and the cotton-simulated terylene short fiber comprises 0-1 percent by weight of calcium sulphate, 1-10 percent by weight of PEG (Polyethylene Glycol) and 1-10 percent by weight of ECDP (Easy Cationic Dyeable Polyester). The invention also provides a preparation method of the cotton-simulated terylene short fiber, comprising the following steps of: slicing the PET; drying a mixture of the calcium sulphate, the ECDP and the PEG and fusing and spinning the mixture into a terylene raw filament at 270-280DEG C by using a profile spinneret; carrying out winding, doffing, balanced bundle collection, wire guiding, pre-stretching and oiling; after primary or secondary stretching, dissolving out partial calcium sulphate in the soaking process by alkali treatment to form mocropores on the surfaces of fibers; and finally carrying out tense heat setting, curling, loosed heat setting, cutting and packaging to obtain the cotton-simulated terylene short fiber. The invention solves the problems that a compound spinning process in the prior art is not only complicated, but also has low yield and makes up the defects that the terylene has poor hydrophilicity and the textile is humid and muggy to wear.

Owner:XUZHOU SILK FIBER TECH

Ultra-coarse denier flat shredded and method for making same

ActiveCN101135067AMeet needsRealize differentiated productionFilament/thread formingEngineeringMechanical engineering

The present invention provides one kind of ultra heavy denier flat cross section filament with 10-20 monofilaments, monofilament fineness of 60-120 D and twist number of 90-110 twist / m, and its production process. The flat cross section filament, also named as imitation linen filament, is one new type of Vicat fiber produced through a special process and with flat cross section. It has excellent performances of both Vicat fiber and hemp fiber, and possesses high marketability.

Owner:YIBIN GRACE

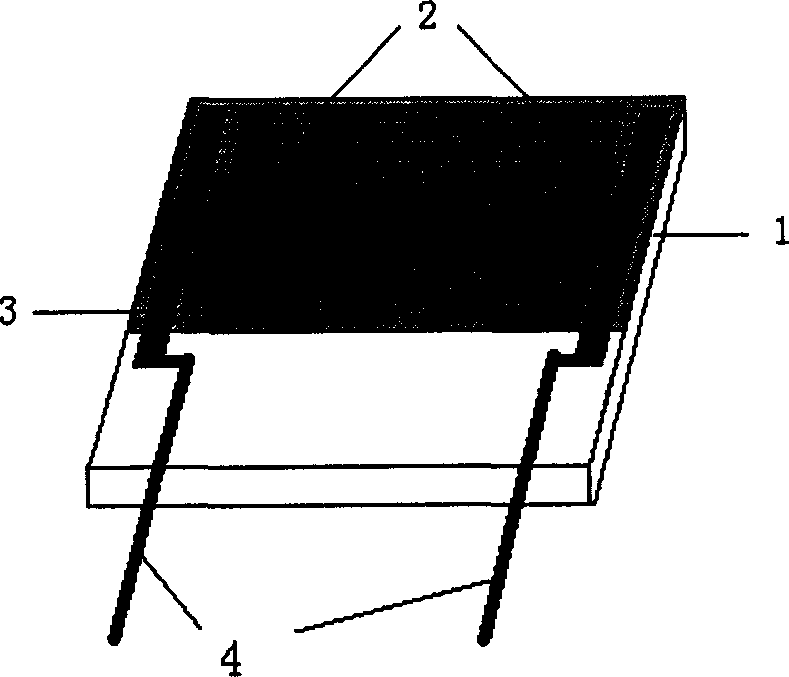

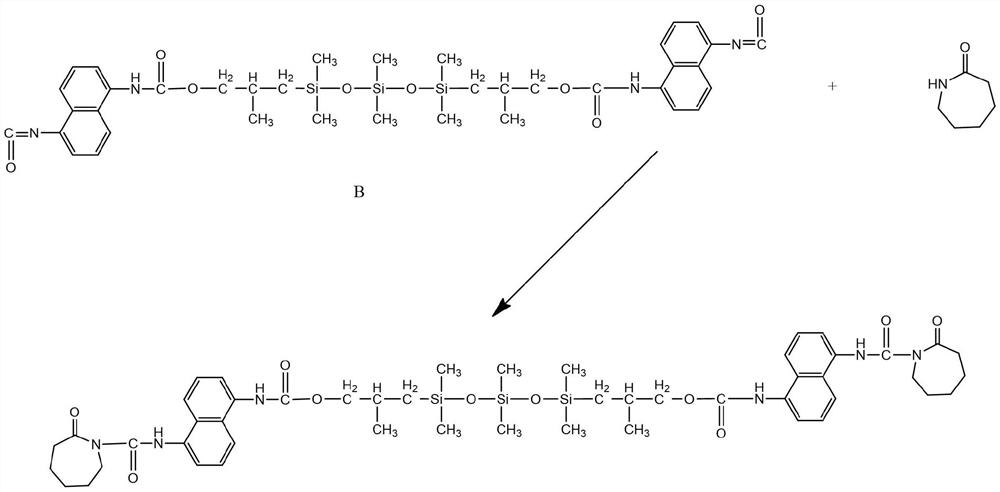

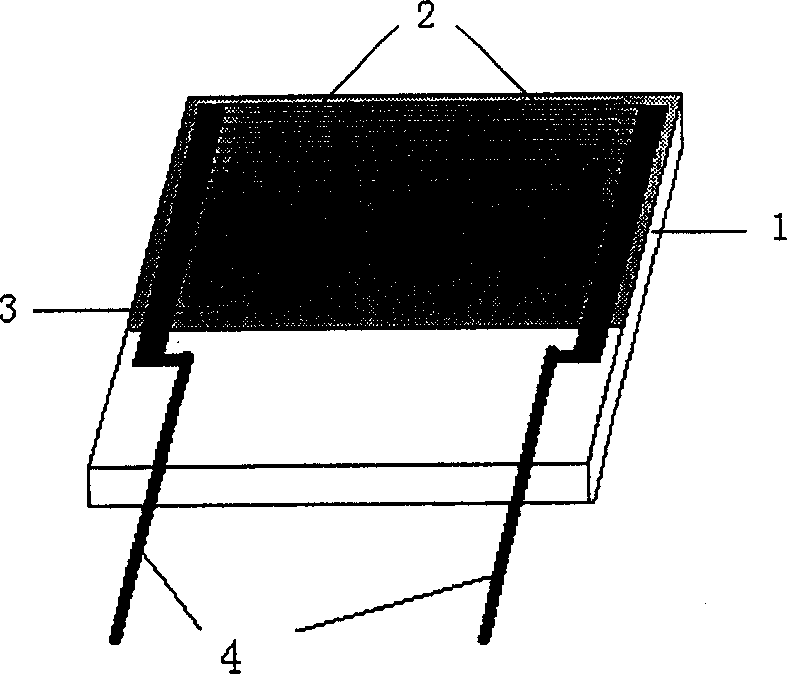

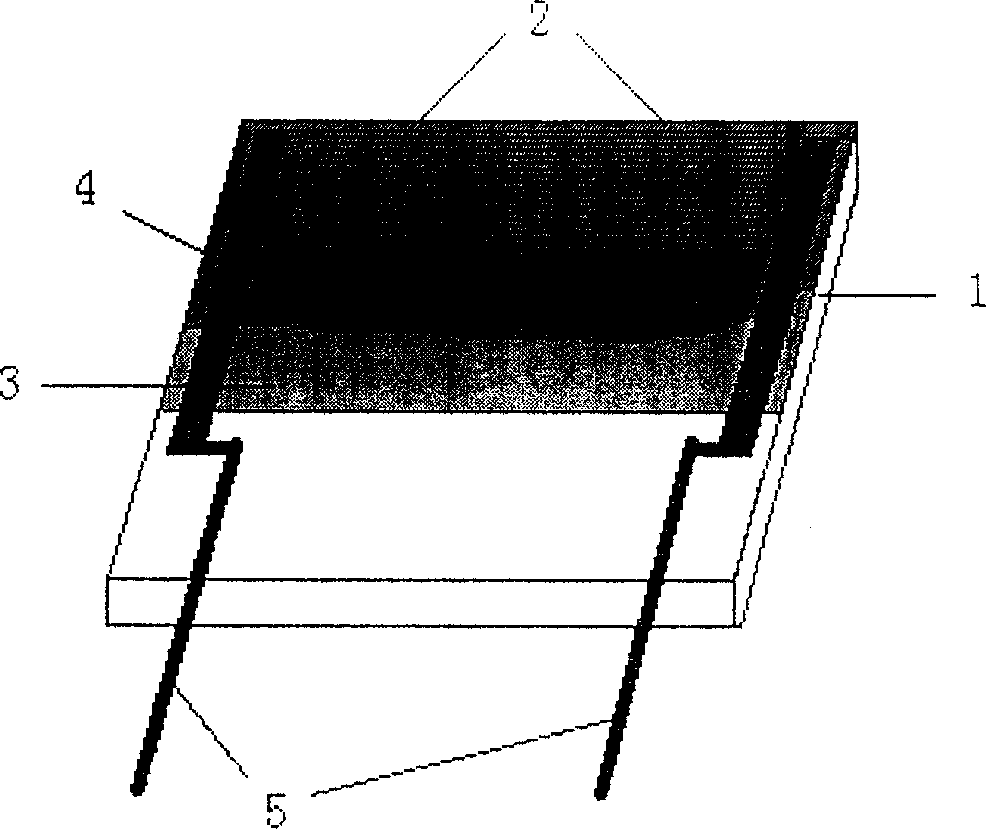

Polyimide film miniature quick-response humidity sensing element and manufacturing method thereof

ActiveCN101949878AMoisture absorption fastDecorative surface effectsChemical vapor deposition coatingCapacitanceSputtering

The invention relates to a polyimide film miniature quick-response humidity sensing element, which is in a high polymer parallel-plate capacitance structure, an upper metal layer is an upper electrode, a lower metal layer is a lower electrode, and a humidity-sensitive layer is arranged between the upper metal layer and the lower metal layer. The polyimide film miniature quick-response humidity sensing element is characterized in that the upper electrode is in grid arrangement, and the humidity-sensitive layer takes polyimide as a humidity-sensitive film. In a manufacturing method, the polyimide film miniature quick-response humidity sensing element is manufactured by adopting a micro-electronics process through processes such as the cleaning and oxidizing of pole pieces, the evaporation of the lower electrode, polyimide coating, imidization, the sputtering of the upper electrode, primary photoetching, secondary photoetching, third-time photoetching, sectioning, bonding, capsulation and the like. In the polyimide film miniature quick-response humidity sensing element, novel polyimide is selected as a humidity-sensitive material, the response speed of moisture absorption and dehumidification is quick; the structure of the upper and the lower electrodes is favorable for detecting the subtle change of water concentration in the humidity-sensitive film; in addition, the controlled range of the film thickness contributes to quick response, and the index of the response speed reaches 500 ms.

Owner:LANZHOU JIAOTONG UNIV

Preparation and preparation process for purifying storage environment and regulating environmental humidity

ActiveCN102284270ALow costStrong adsorption functionOther chemical processesLighting and heating apparatusPerfect stateChemistry

The invention provides a preparation process of a preparation for purifying a storage environment and regulating environmental humidity. The preparation can be used for absorbing ammonia, formaldehyde, residual hydrogen phosphide and other gases in the storage environment, and regulating the humidity of local storage space, so that the storage space is maintained in a perfect state. The preparation comprises the following main components: calcium chloride, starch, perlite, activated carbon, diatomaceous earth and zeolite. The preparation process mainly comprises the following steps: deep physical modification (enhancement of a specific surface area), crushing and granulation, and mixed package. The preparation is in accordance with natural green, environment-friendly and low-carbon concepts, has obvious effects on purifying the storage environment and regulating the humidity of the storage environment, and has a simple process.

Owner:BEIJING YINGFENG LITAI TECH TRADE

Blended yarn

The present invention is one kind of blended yarn of bamboo fiber and chemical fiber, and solves the problem of insufficiency of natural textile material. Fabric of the blended yarn has the features of bacteriostasis, fast moisture absorption, coolness and soft hand feeling, and the ultimate fabric has stiffness and draping and can meet the requirement as costume material.

Owner:上海日舒棉纺织厂

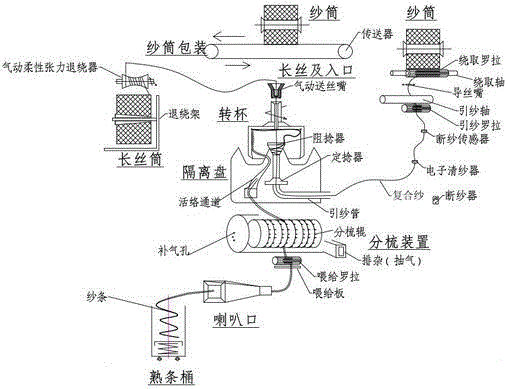

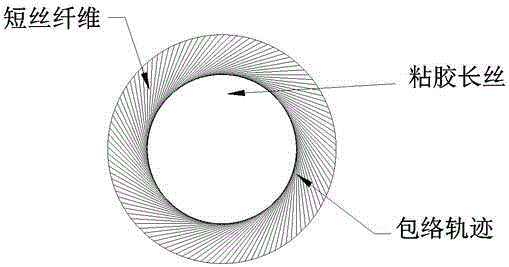

Core-sheath composite yarn and preparation method thereof

ActiveCN106435899AGuaranteed StrengthChange yarn functionContinuous wound-up machinesOpen-end spinning machinesEngineeringYarn strength

The invention discloses a core-sheath composite yarn and a preparation method thereof; the core-sheath composite yarn is made from staple yarn fiber and viscose filament yarn by enveloping, wherein the staple yarn fiber is an enveloping material, the viscose filament yarn is a yarn core, the staple yarn fiber is 0.8-1.3 d, and the viscose filament yarn is 120-300 d. The core-sheath composite yarn is made by enveloping via rotor spinning. The core-sheath structure ensures yarn strength and forms a multifunctional yarn; yarn functionality is changed by adjusting geometry of the core and sheath and fiber properties through spinning process according to the different specific applications and different performance requirements of yarn products, and series of functional products are derived accordingly.

Owner:YIBIN WEILUO TEXTILE

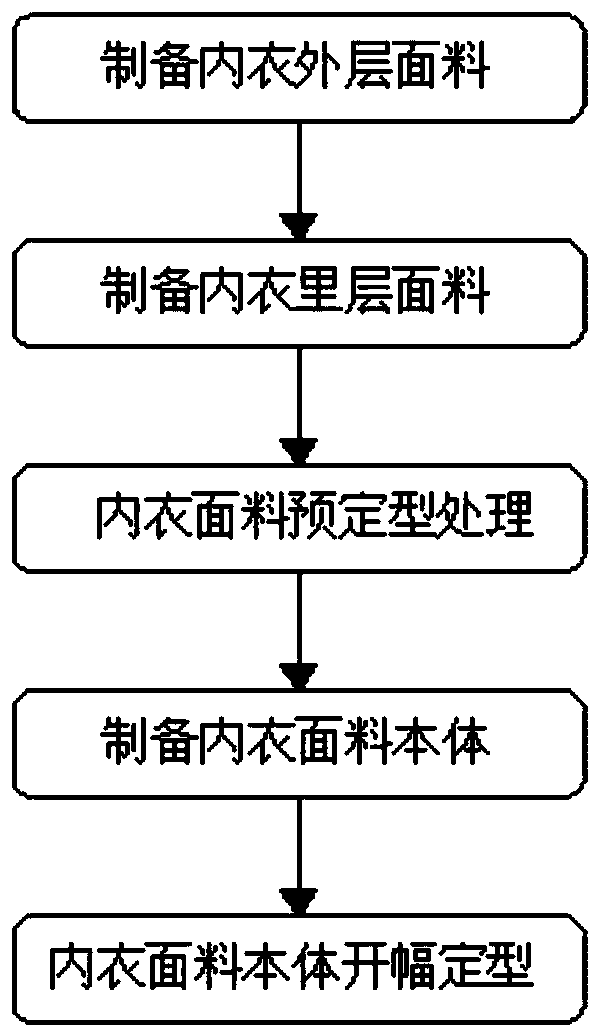

Antibacterial comfortable underwear knitted fabric

InactiveCN110281618AAntibacterial comfortGood antibacterial and deodorant effectSynthetic resin layered productsFiberYarn

The invention discloses antibacterial comfortable underwear knitted fabric. The knitted fabric comprises a underwear knitted fabric body, underwear outer layer fabric and underwear inner layer fabric, wherein the underwear knitted fabric body is formed by connecting the underwear outer layer fabric and the underwear inner layer fabric by spinning and weaving. The underwear inner layer fabric of the antibacterial comfortable underwear knitted fabric disclosed by the invention is composite fiber yarn made by mixing chitin fiber yarn and bamboo fiber yarn, and the chitin fiber yarn per se has excellent antibacterial and bacteriostatic effects; meanwhile, bamboo quinone in the bamboo fiber yarn has antibacterial, anti-mite and deodorant properties, and chlorophyll and copper chlorophyll in the bamboo fiber yarn have relatively good deodorant effect, so that the antibacterial comfortable underwear knitted fabric has the antibacterial and deodorant effects.

Owner:JIHUA 3542 TEXTILE CO LTD

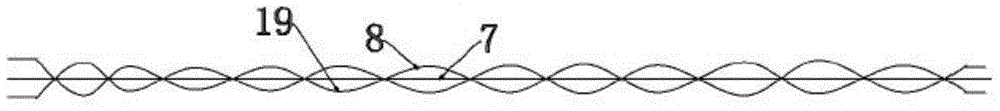

Special high-elasticity yarn and fabric thereof

InactiveCN110257989AIncrease elasticityImprove breathabilityWeft knittingWoven fabricsMoisture absorptionEngineering

The invention discloses a special high-elasticity yarn, which is characterized by comprising an outer wrapping fiber and a core yarn, wherein the outer wrapping fiber is spirally wrapped outside the core yarn; the outer wrapping fiber is a high-elastic composite yarn; the high-elasticity composite yarn is a bi-component composite yarn prepared by conjugate spinning PBT and PET through a double-screw spinning machine; the mass ratio of PBT to PET in the high-elasticity composite yarn is 58 to 42; the high-elasticity composite yarn is subjected to wet heat treatment after spinning, since PBT and PET two components can contract differently, the fiber generates longitudinal stress and torsion deviating from the longitudinal axis at the same time, presenting a double-spiral three-dimensional structure; the core yarn is PTT filament yarn; and the PTT filaments are arranged in parallel without twisting. The special high-elasticity yarn has good elasticity, high yarn strength, good elasticity recovery, rapid moisture absorption and dissipation, good air permeability, dry and soft touch feeling, good hand feeling, good color fastness and good use effect.

Owner:江苏三丰特种材料科技有限公司

Super thin spring socks and producing method

The present invention discloses super thin stretch socks with wear comfort and long service life and suitable for being worn in summer especially and the production process. The super thin stretch socks are knitted with super fine denier elastic fiber and super fine denier cotton fiber, hemp fiber or other natural fiber and through spiral weaving. During production in a silk stocking machine, super fine denier elastic fibers are fed through two symmetrical yarn paths while super fine denier cotton fibers, hemp fibers or other natural fibers are fed through other two symmetrical yarn paths, and the super thin stretch socks are woven in a process similar to that of silk socks.

Owner:刘训林

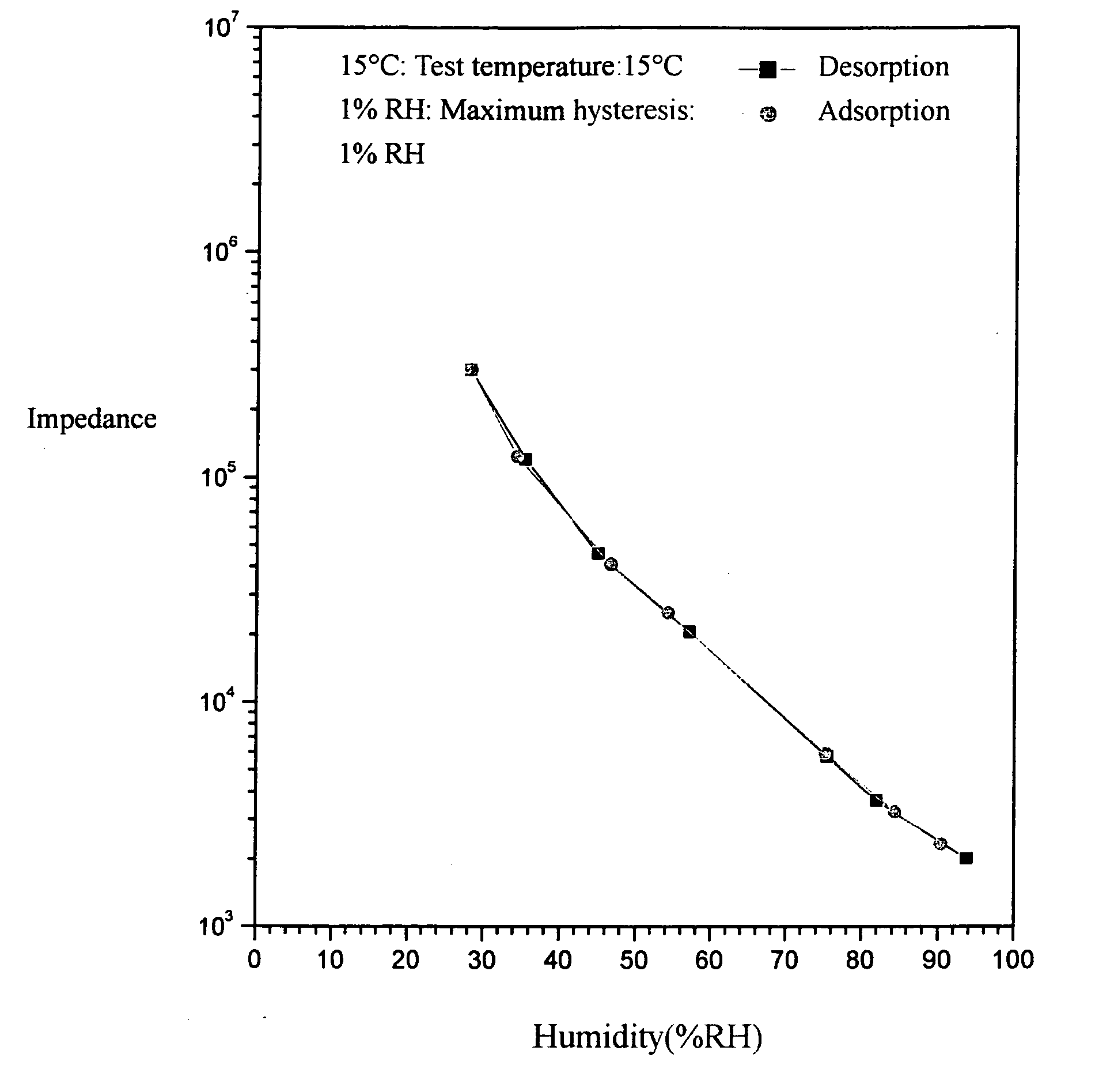

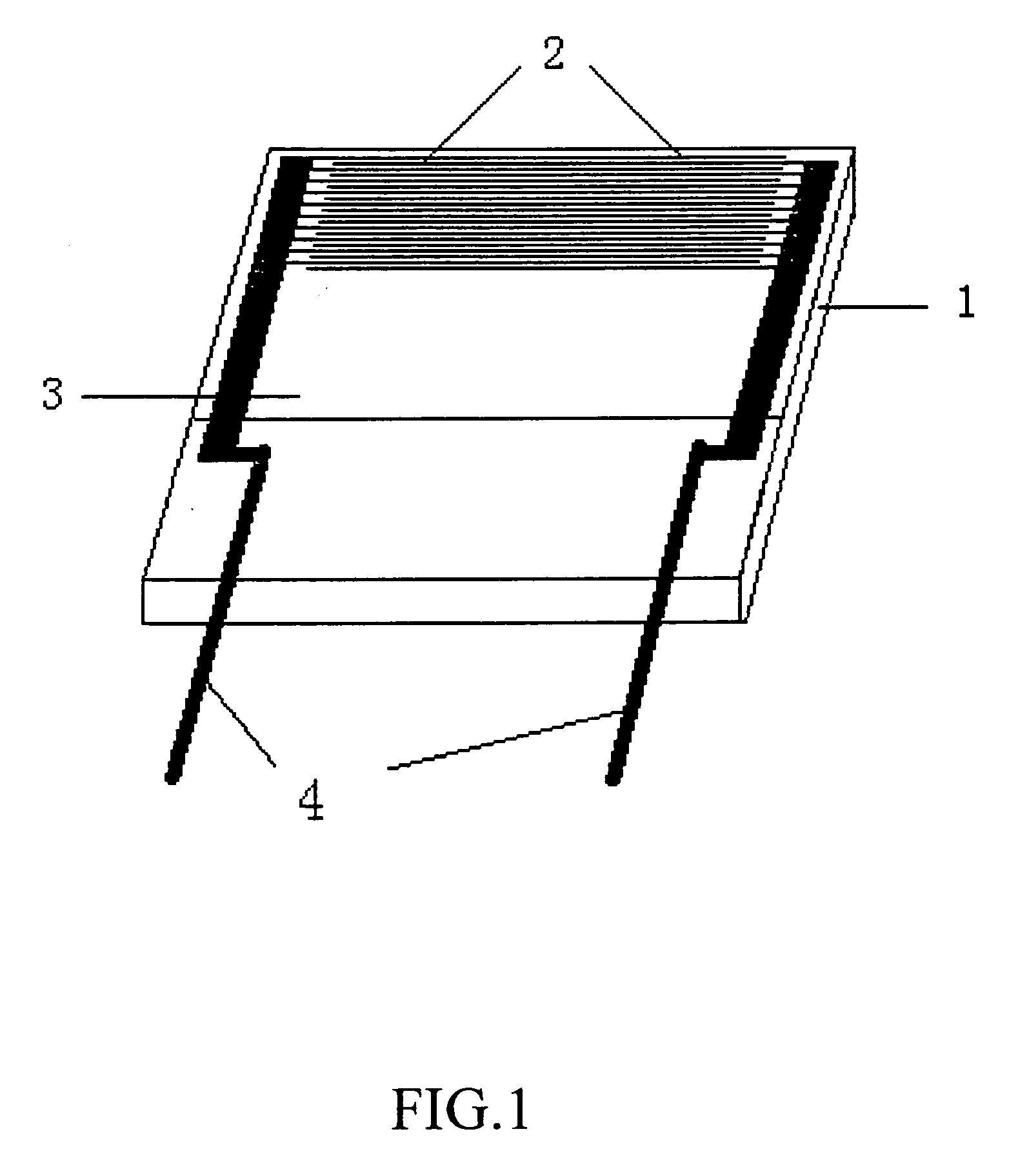

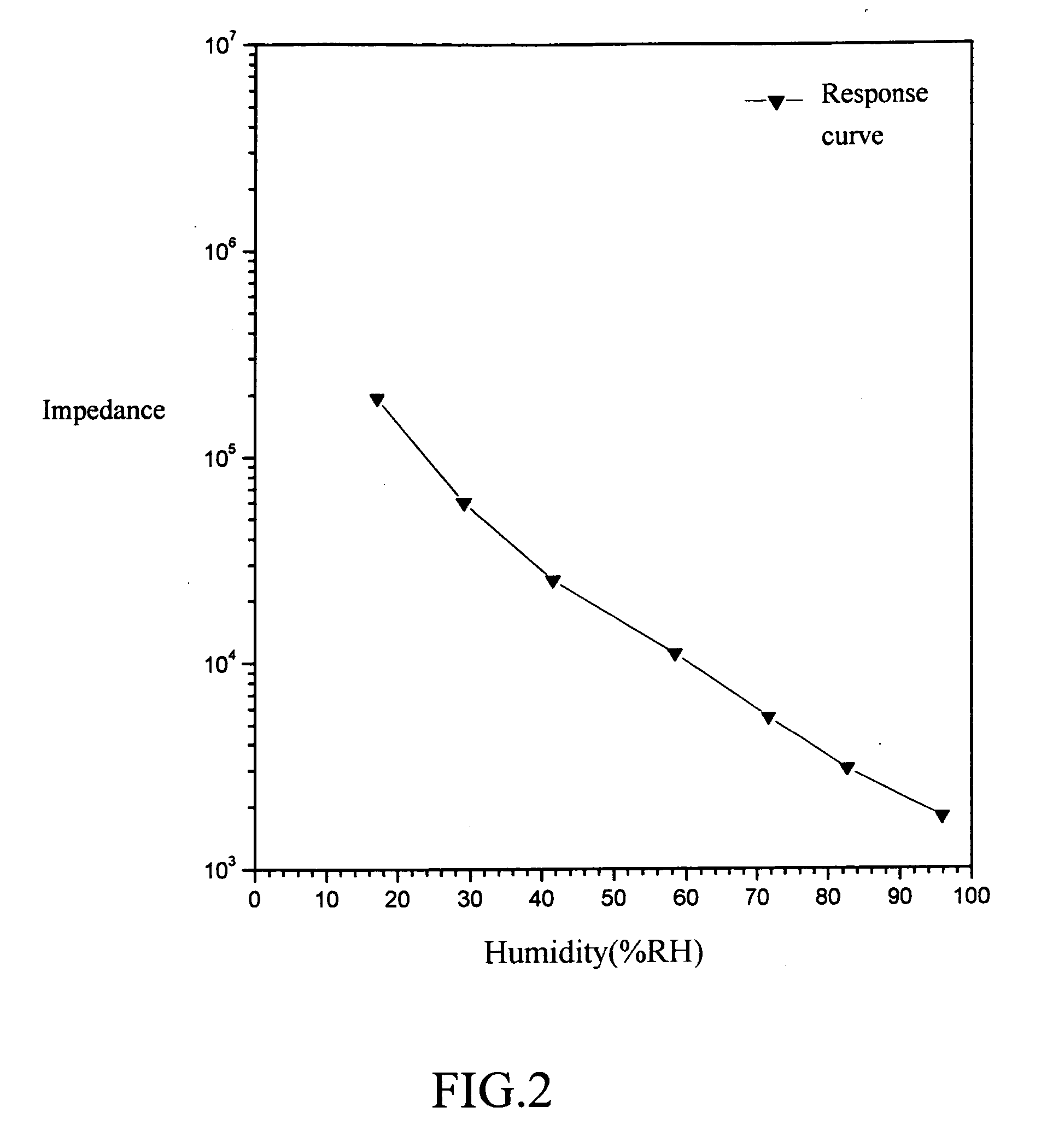

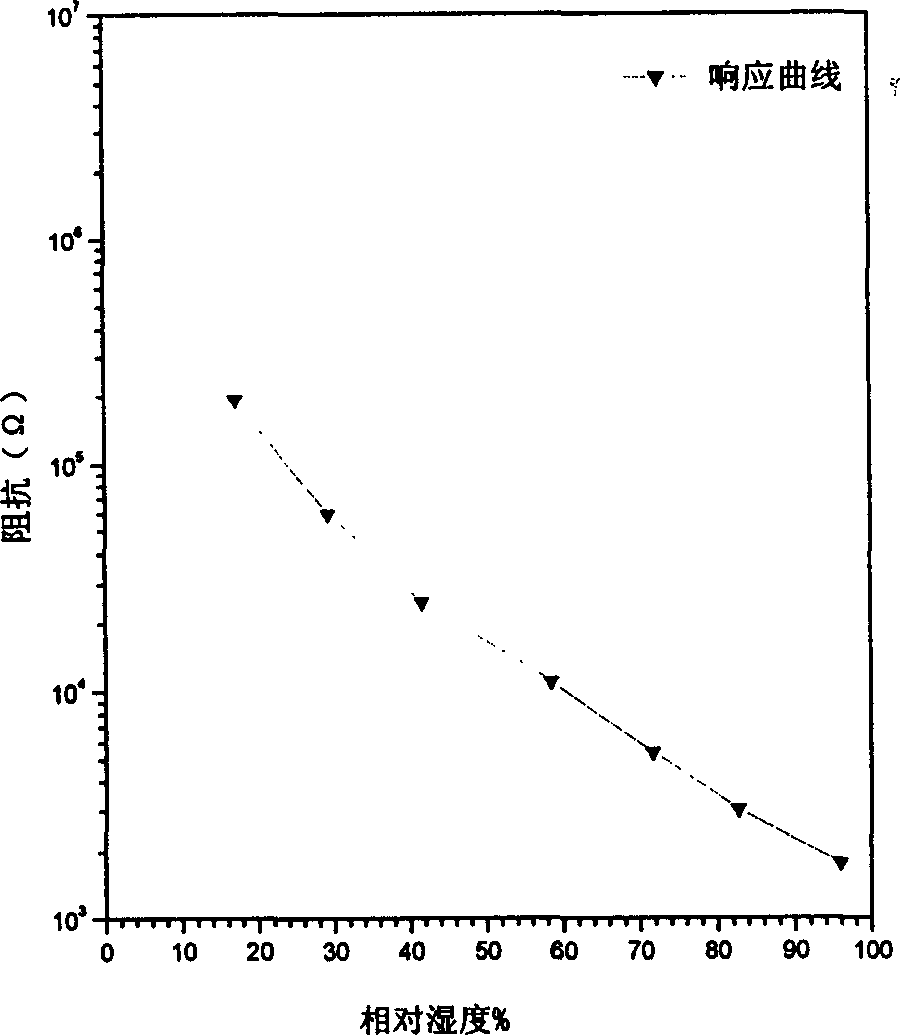

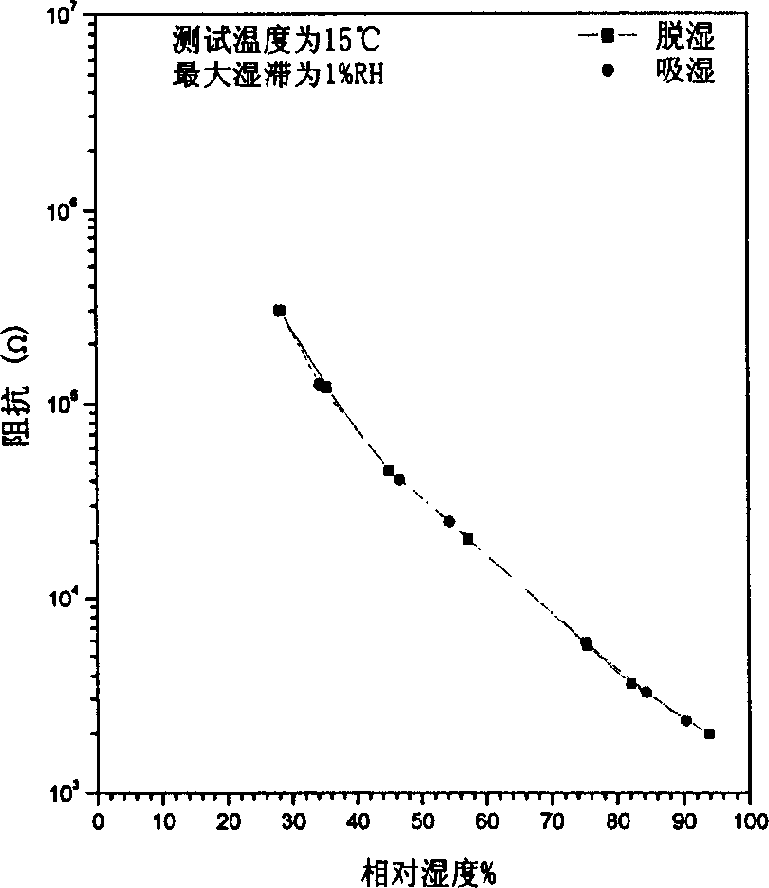

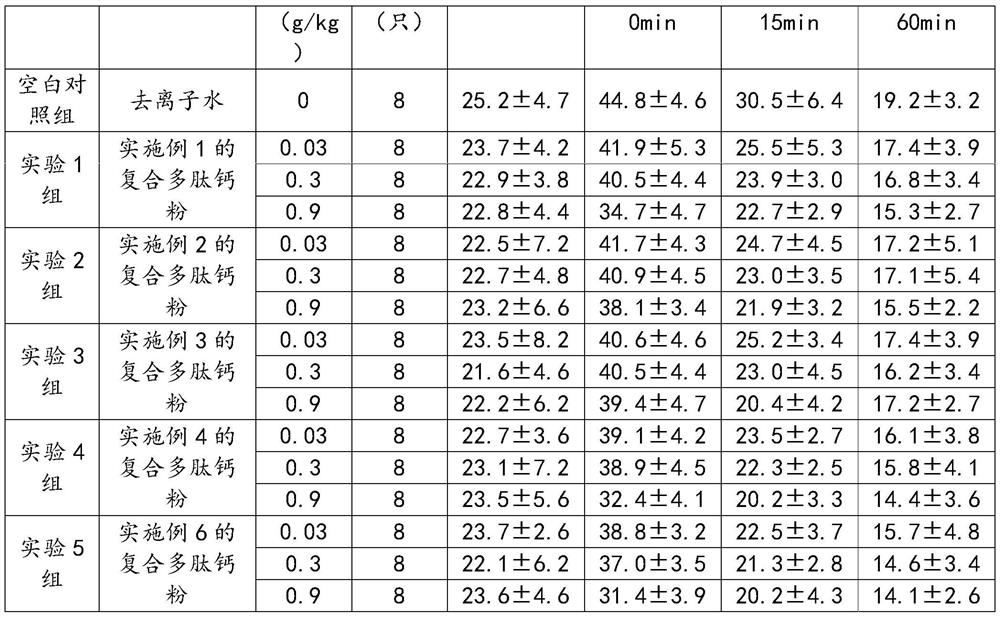

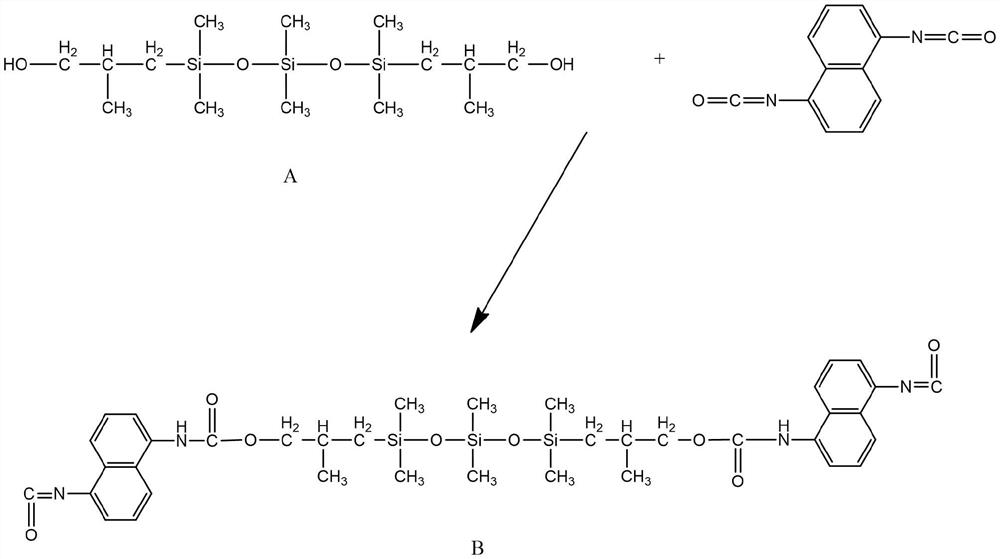

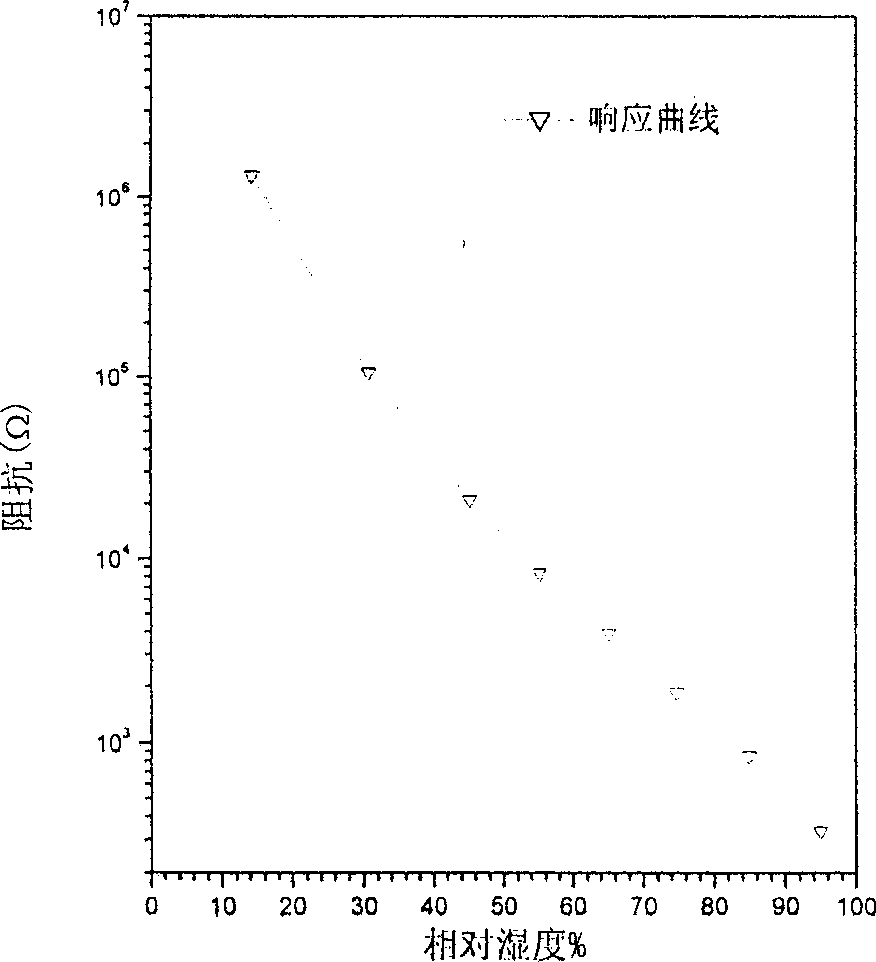

Resistive thin film humidity sensitive device based on silicone-containing copolymer and its preparation method

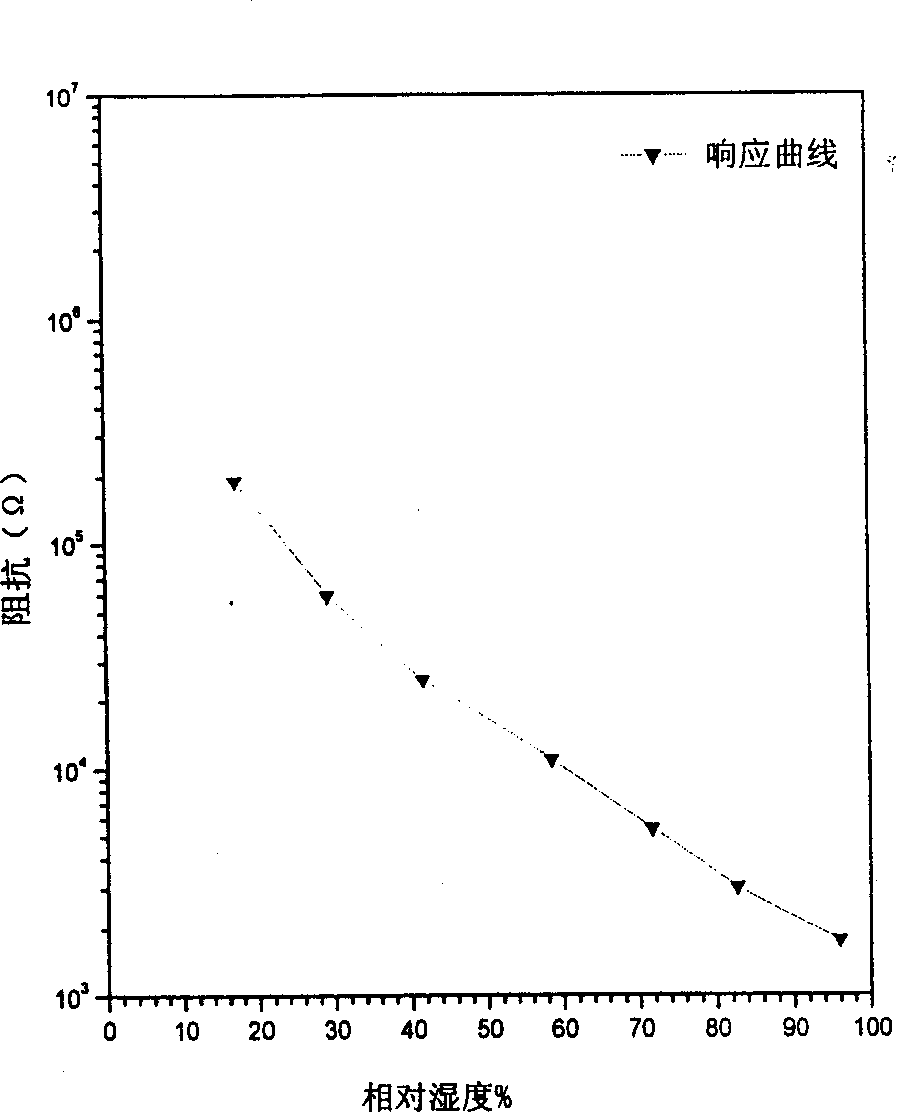

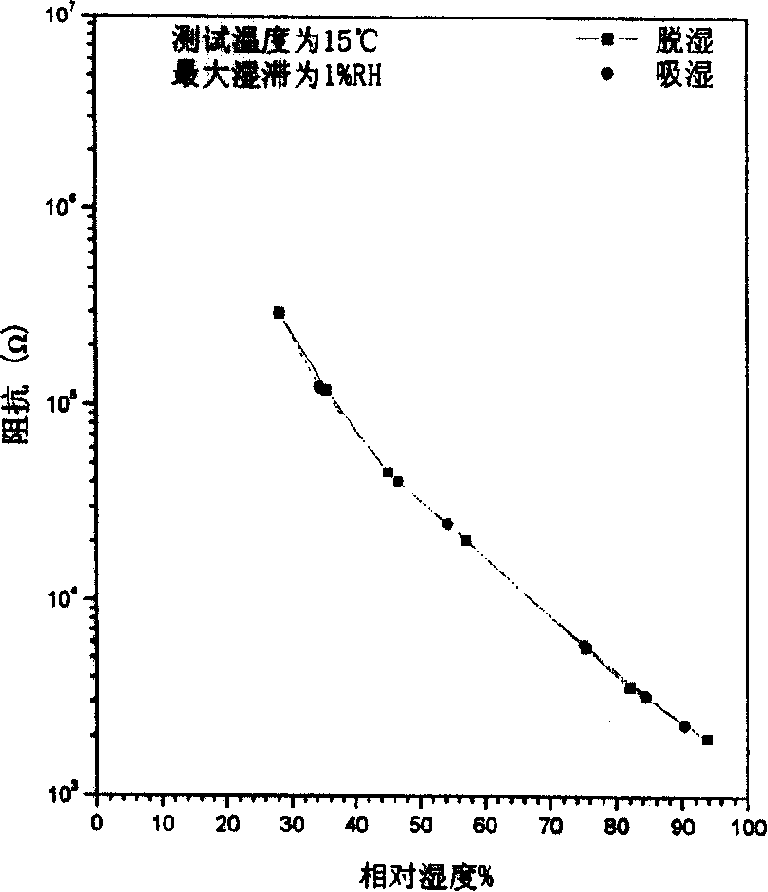

InactiveUS20070039385A1Small volumeLow costUsing mechanical meansMaterial resistanceElectrical resistance and conductanceCationic polyelectrolytes

Disclosed is a resistive thin film humidity sensitive device based on silicone-containing copolymer and its preparation method. The device includes a microlite glass substrate; a plurality of interdigital gold electrode pairs, which are evaporated and photolithographically defined onto the microlite glass substrate; lead lines connecting to the interdigital gold electrodes; and a humidity sensitive film coated onto the microlite glass substrate and surface of the interdigital gold electrodes, and the humidity sensitive film is a cationic polyelectrolyte-silicone containing copolymer. The method for preparing the device includes the steps of: (1) dipping a microlite glass substrate having interdigital gold electrodes in a solution containing humidity sensitive materials by a Dip-Coater, and obtaining a humidity film after lifting and heat treatment; and (2) aging the interdigital gold electrodes coated with humidity sensitive film on microlite glass substrate at a specific electric condition, humidity and temperature condition, and obtaining the resistive-type thin film humidity sensitive device based on silicone-containing copolymer. Advantages of the present invention include broad humidity detection range, high sensitivity, fast response speed, simple process for production, low cost, and is widely applicable to detection and control of a process and environmental humidity.

Owner:HUANG DEHUAN

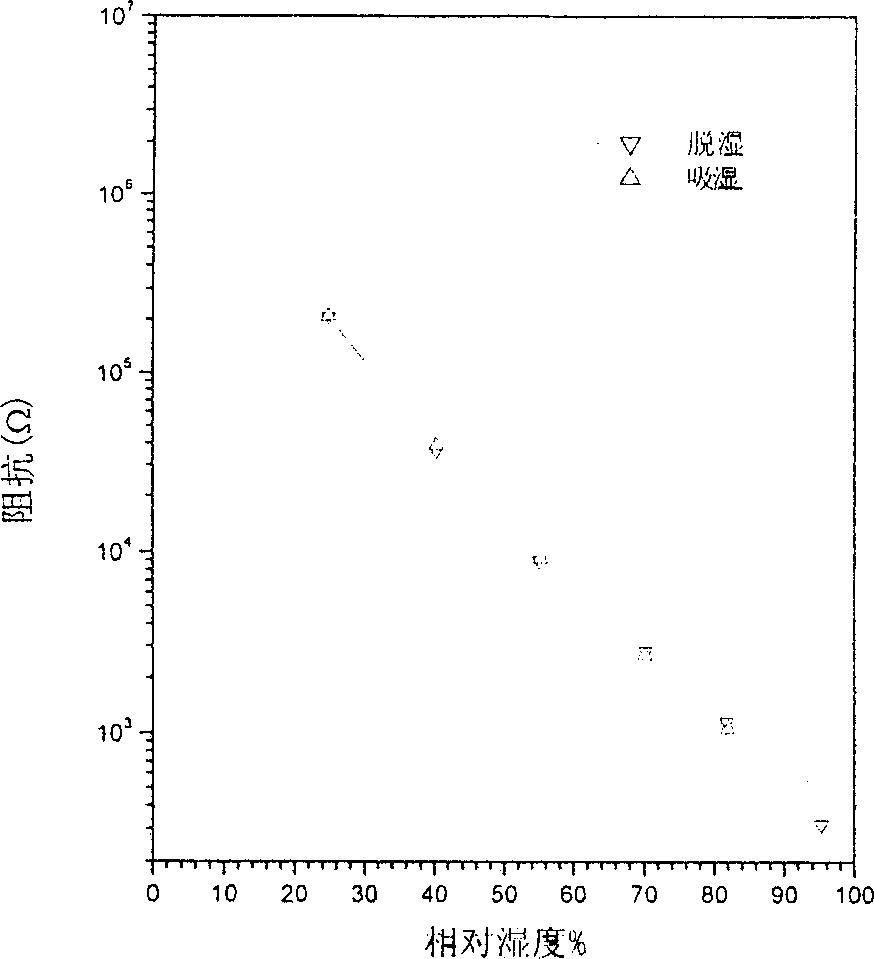

Siliceous copolymer resistor type thin film humidity sensitive element and method for making same

InactiveCN1655375ALower impedanceReduce volumeSolid-state devicesMaterial moisture contentDewCopolymer

This invention discloses a siliceous copolymer resistance thin film dew sensor and its process method, wherein the sensor comprises the following parts: micro crystal glass base with multiple pairs of crossed gold electrode connected with wires on the surface; dew sensitive film coated on the surface of the micro crystal glass and the crossed gold electrode, wherein the film is the siliceous positive ion electrolyte copolymer. The method comprises the following steps: a, dipping the micro crystal glass and the crossed gold electrode into the dew sensitive liquid by dipping machine; pulling and taking out the electrode for thermal process to make the dew sensitive film; b, electrifying the micro crystal glass with dew sensitive film and the electrode under certain temperature and the humidity to get the dew sensor.

Owner:上海华实纳米材料有限公司

Cotton-simulated terylene short fiber and preparation method thereof

ActiveCN101831727BGuaranteed spinnabilitySimple processHollow filament manufactureFilament manufacturePolyesterPolyethylene glycol

Owner:XUZHOU SILK FIBER TECH

Detergent pack

InactiveUS20160222330A1Moisture absorption fastImprove stabilityOrganic detergent compounding agentsOrganic/inorganic per-compounds compounding agentsCarboxylic acidWater soluble

A moisture-permeable detergent pack comprising a plurality of water-soluble unit-dose detergent products the products comprising a phosphate-free detergent composition and an enveloping material the detergent composition comprising:a) a moisture sensitive ingredient; andb) from 15% to 50% by weight of the product of an aminocarboxylic complexing agent wherein the aminocarboxylic complexing agent is in the form of a hygroscopic particle.

Owner:THE PROCTER & GAMBLE COMPANY

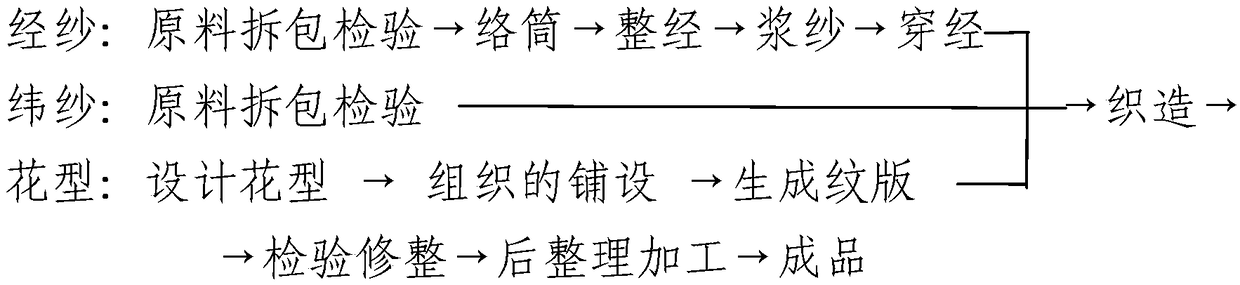

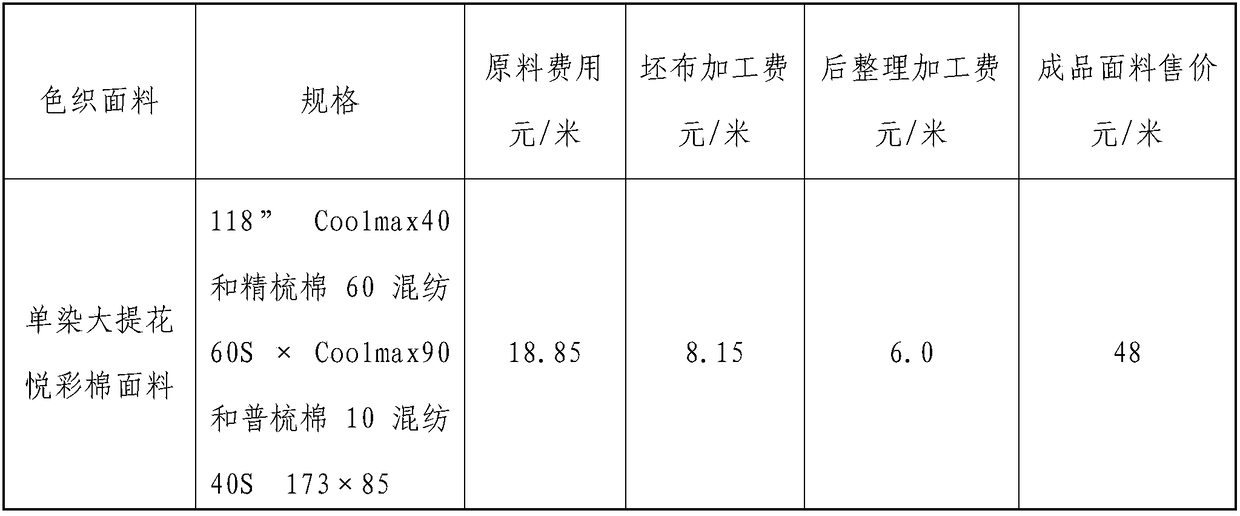

Single-dyed jacquard Yuecai cotton fabric and production method thereof

The invention discloses a single-dyed large jacquard Yuecai cotton fabric and a production method thereof. According to the method, warp yarn is sequentially subjected to the processes of spooling, warping, sizing and drawing-in and then woven in combination with weft yarn according to a pattern card form, and then the finished product is formed after the processes of finishing and after-finishingin sequence. Blended yarn of 60% of combed cotton fibers and 40% of Coolmax moisture-absorbing and quick-drying fibers is adopted as the warp yarn, the yarn density is 9.8 tex, blended yarn of 90% ofCoolmax moisture-absorbing and quick-drying fibers and 10% of carded cotton fibers is adopted as the weft yarn, and the yarn density is 14.7 tex. The fabric has the advantages of high color stereoscopic impression, soft and comfortable handfeel, moisture absorption and breathability.

Owner:JIANGSU YUEDA HOME TEXTILE

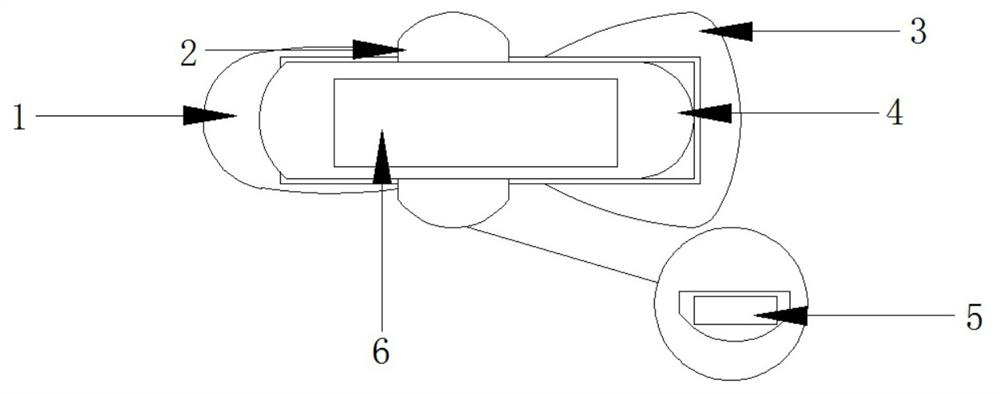

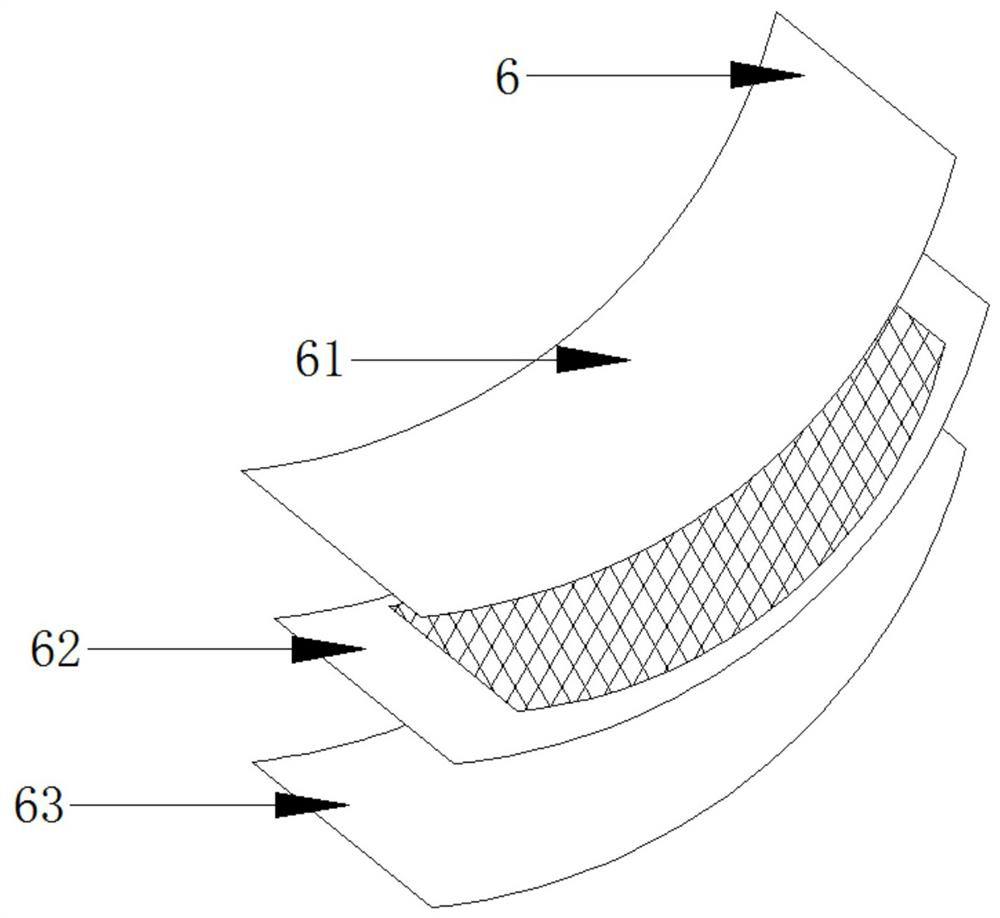

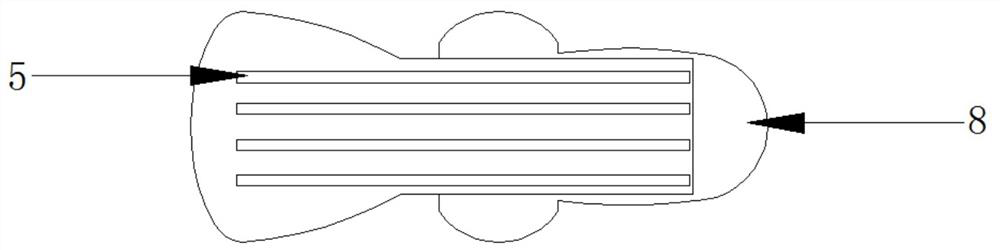

Graphene sanitary napkin core and production method therefor

The invention discloses a graphene sanitary napkin core and a production method therefor. The graphene sanitary napkin core comprises a sanitary napkin body, wherein flanks are arranged and mounted at the left and right sides of the sanitary napkin body, a tail fin is arranged at the bottom end of the sanitary napkin body, a surface layer is arranged and mounted at the middle end of the sanitary napkin body, a functional core is arranged and mounted at an internal middle part of the surface layer, a basilar film is arranged and mounted on the back of the sanitary napkin body, backing adhesives are separately arranged and mounted on the back of the basilar film and backs of the flanks, and materials such as elemental graphene and high-activity bamboo charcoal powder are arranged in the functional core. The graphene sanitary napkin core has natural antibacterial, bacteriostatic, anti-mite and deodorization functions; ionic micro-arrays are formed by high-activity bamboo charcoal, so that durability can be strengthened through webbing the graphene and distributing the graphene into the entire core, and the bactericidal and bacteriostatic effects of the core are improved greatly; and by adding some traditional Chinese medicine ingredients, the feeling of a female's private part can be relieved, meanwhile, off odors can be dispelled, and embarrassments of female in daily lives are relieved.

Owner:佛山市创洁无纺科技有限公司

Spinning method of multi-component blended yarns based on compact spinning

The invention discloses a spinning method of multi-component blended yarns based on compact spinning, and is applied to the technical field of spinning. The method includes the steps: raw material selection: selecting 20-20% of jute fibers, 15-30% of silk fibers, 15-30% of jutecell fibers, 10-30% of apocynum venetum fibers, 5-10% of aloe fibers and 5-10% of tencel fibers in weight percent; sequentially unpacking and mixing the jute fibers, the silk fibers, the jutecell fibers, the apocynum venetum fibers, the aloe fibers and the tencel fibers into strips by existing devices such as an FA002A disk plucker, a ZFA 036 mixing opener, an FA 022-6 multi-bin cotton blender, a ZF1102A card wire opener, an FA046A vibrating cotton box feeder, an FA141A single beater scutcher, an FA224D carding machine and a JWF 1310 drawing frame.

Owner:CHAOHU YOUNGOR COLOR SPINNING TECH CO LTD

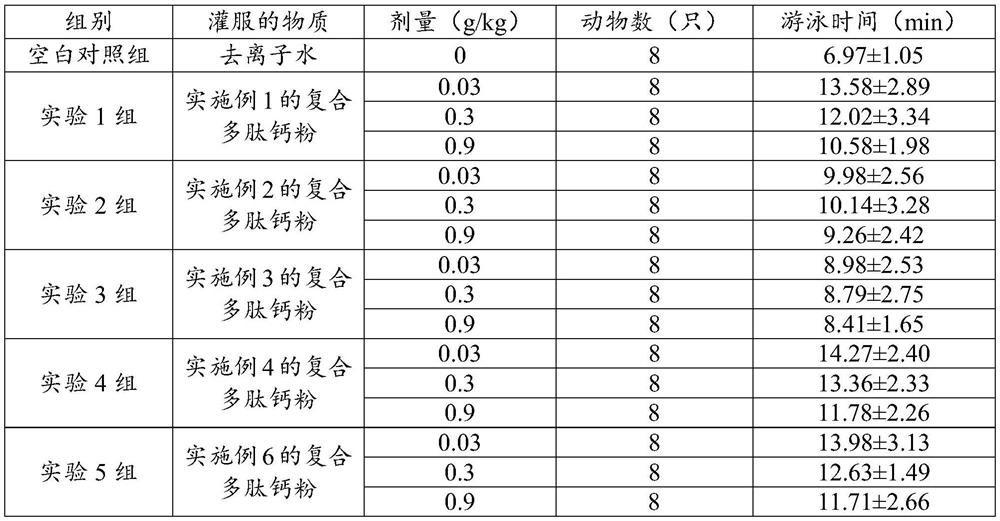

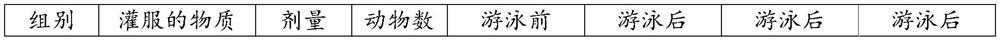

Composite polypeptide calcium powder and preparation method and application thereof

PendingCN112262993AImprove bioavailabilityReduce competitive antagonismOrganic active ingredientsHydrolysed protein ingredientsBone qualityImmunity

The invention belongs to the technical field of health care products, and particularly relates to composite polypeptide calcium powder and a preparation method and application thereof. The composite polypeptide calcium powder comprises the components in percentage by weight: 20-30 parts of bone collagen peptide, 10-30 parts of soybean peptide, 3-15 parts of sea cucumber peptide, 3-6 parts of oyster peptide, 2-5 parts of ginseng peptide, 15-25 parts of maltodextrin, 5-15 parts of fruit powder, 5-8 parts of calcium aspartate and 3-6 parts of casein phosphopeptide. According to the composite polypeptide calcium powder, plant-derived bioactive peptides and animal-derived bioactive peptides are combined, so that the body immunity can be enhanced, the immune system of the body can be regulated,the physical fatigue can be relieved, the bone mineral density can be increased, and the composite polypeptide calcium powder is suitable for adjuvant therapy of patients suffering from susceptible fatigue and osteoporosis.

Owner:上海嘉香实业有限公司

Preparation method of nano zinc carbon antibacterial and anti-mite fiber

InactiveCN111270338AChange permeabilityAchieve bactericidalMonocomponent cellulose artificial filamentMonocomponent polyesters artificial filamentBiotechnologyMicroorganism

The invention discloses a preparation method of a nano zinc carbon antibacterial and anti-mite fiber, and belongs to the technical field of antibacterial and anti-mite fiber materials. The preparationmethod comprises the following steps of mixing particles, zinc oxide and carbon through multiple crushing treatments to obtain primary micro-powder; dispersing the above primary micro-powder in a spinnable spinning solution to form a mixed spinning solution; adding the primary micro-powder to the spinning solution through a melt spinning process, and spinning into the fiber; and the formed fiberhas the advantages of being permanent antibacterial, anti-mite, moisture-absorbing and quick-drying. Compared with ordinary fibers, the fiber prepared by the invention has a variety of strain antibacterial tests. According to the preparation method of the nano zinc carbon antibacterial and anti-mite fiber provided by the invention, the permeability of a bacterial cell wall can be changed, so thatenzymes, coenzymes and metabolic intermediate products in the bacteria overflow, thus respiratory functions of microorganisms are stopped and the microorganisms die, so as to achieve the functions ofsterilization and bacteriostasis.

Owner:江苏康溢臣生命科技有限公司

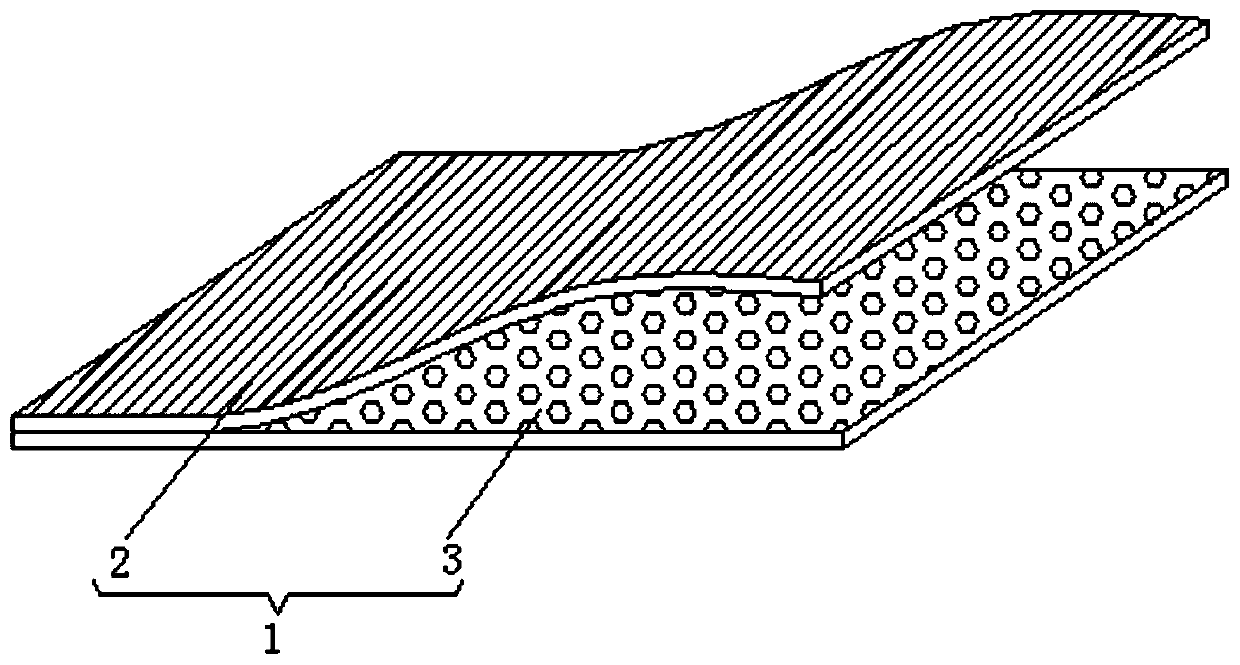

Production process of high-breathability fabric for western-style clothes

InactiveCN113249969AImprove breathabilityGood hygroscopicitySynthetic resin layered productsLaminationPolyesterCotton fibre

The invention discloses a production process of a high-breathability fabric for western-style clothes, and relates to the field of fabrics. The production process comprises the following steps of spinning silk fibers to form an outer layer fabric; placing the outer layer fabric in anti-wrinkle finishing liquid, performing treating by adopting a two-dipping and two-padding mode, firstly performing pre-drying, and then performing baking to obtain an anti-wrinkle outer layer fabric; spinning polyester fibers to form a middle-layer fabric; spinning cotton fibers to form an inner-layer fabric; and bonding and pressing the anti-wrinkle outer-layer fabric, the middle-layer fabric and the inner-layer fabric together by adopting an adhesive, so as to obtain the high-breathability fabric for the western-style clothes. The fabric has high breathability and hygroscopicity and is comfortable to wear; and after the outer-layer fabric is placed in the anti-wrinkle finishing liquid to be finished, an anti-wrinkle agent reacts with active groups on the silk fibers to limit relative slippage or deformation of fiber macromolecular chains due to external force, so that the wrinkle resistance is improved, and the fabric for the western-style clothes is not prone to wrinkle and good in wrinkle resistance.

Owner:安徽弋尚纺织科技有限公司

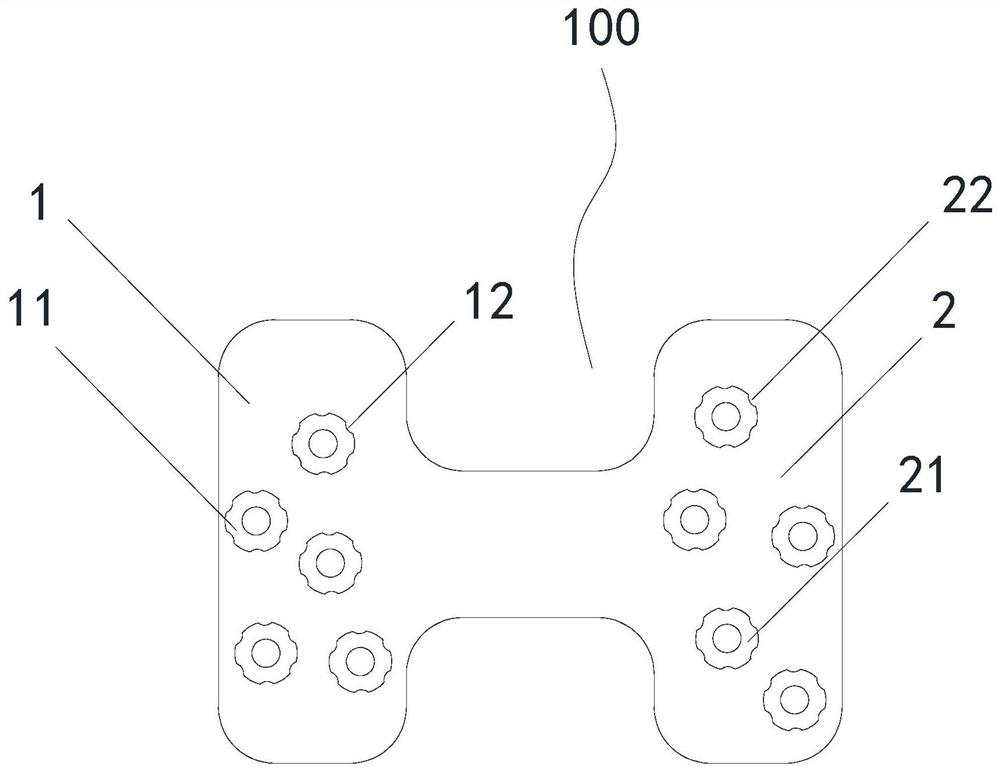

Cotton-like modified polyester filament yarn and preparation method thereof

InactiveCN111647987AMoisture absorption fastDrain fastHollow filament manufactureFilament/thread formingPolymer scienceMoisture absorption

The invention discloses cotton-like modified polyester filament yarn and a preparation method thereof. The surface of the H-shaped filament yarn is dissolved into uneven holes, and then the uneven holes gradually develop into the interior of fiber. Water-soluble polyester in the fiber is dissolved, the fiber is dissolved into a plurality of small holes penetrating through two H-shaped parallel hole chambers, and the small holes and the two H-shaped parallel hole chambers form longitudinal and transverse penetrated channels with moisture absorption, moisture removal and air permeation functions. The fabric woven from the filament yarn is light in weight, plump in hand feeling and soft in luster, and has the functions of quick moisture absorption, perspiration and air permeation.

Owner:太仓逸枫化纤有限公司

Method for making ramie blended fiber towel

A manufacturing method of a ramie blend fiber towel relates to the technical field of the ramie weaving technology. The manufacturing method comprises the steps of: 1, combining two ramie blended yarns by using a doubling winder and then winding to form a bobbin; 2, feeding the combined bobbin into a doubling and twisting machine for twisting; 3, winding the twisted yarns into bobbin yarns and weaving to form grey cloth; 4, immerging and steaming the grey cloth through a solution, removing a sizing agent and cotton yarn impurities; deoxidizing, dyeing, enzyme-washing, softening, drying and sewing to form a towel. The manufacturing method of the ramie blend fiber towel avoids the problems of exposure of hairs due to too high elasticity of the ramie fibers, serious itchy feeling in use and the like, has few hairs, high strength, good abrasive resistance and fast moisture absorption and moisture diffusion, is anti-microbial and mildew-proof, anti-static, anti-UV, flexible, comfortable, and not easy to generate peculiar smell in the rainy weather.

Owner:和盛包装科技(海宁)股份有限公司

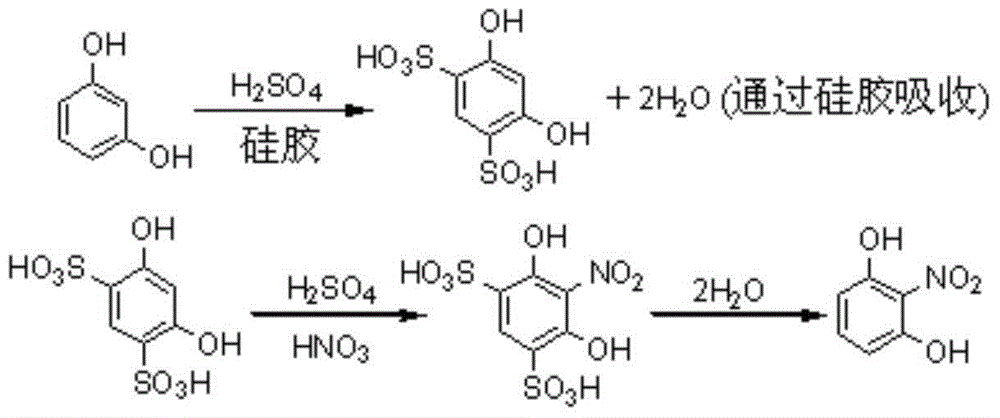

Method of synthesizing 2-nitroresorcinol by utilizing silica gel as assistant dehydrant

InactiveCN103910637AImprove performanceImprove adsorption capacityOrganic compound preparationSulfonic acid preparationIce waterSynthesis methods

The invention relates to a synthesis method of 2-nitroresorcinol, and particularly relates to a method of synthesizing 2-nitroresorcinol by utilizing silica gel as an assistant dehydrant. The method includes: mixing concentrated sulfuric acid and concentrated nitric acid to obtain sulfuric-nitric mixed acid; mixing resorcinol and the silica gel, adding the mixture of the resorcinol and the silica gel into a reactor, slowly adding dropwise concentrated sulfuric acid, cooling with an ice-water bath, adding dropwise the sulfuric-nitric mixed acid, adding crushed ice and urea, subjecting the mixture to steam distillation, collecting fractions, refluxing and dissolving the solid obtained by suction filtration with the ratio of the resorcinol to the ethanol having a concentration of 50% being 1:4, taking out after the solid is fully dissolved, cooling with ice water, and subjecting the precipitate to suction filtration, washing and drying to obtain a finished product. In the method, the silica gel is adopted as the dehydrant and has excellent performances, and therefore the yield of the product is increased and can be higher than 44%, so that obvious economic benefit is generated. By adoption of the silica gel for dehydration, reaction conditions are mild and the production cost is reduced.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Urine isolating composite fabric infantile pad

InactiveCN107234843AMoisture absorption fastImprove water absorptionPersonal careSynthetic resin layered productsPolyesterSurface layer

The invention discloses a baby urine-proof composite fabric protective pad, comprising: a surface care layer, a middle water storage layer and a bottom waterproof layer, the surface care layer is arranged on the upper surface of the middle water storage layer, and the middle water storage layer Set on the upper surface of the bottom waterproof layer, the surface care layer is a health-care fabric made of milk fiber and polyester fiber blend, and the middle water storage layer is a moisture-absorbing and antibacterial fabric made of flax fiber and bamboo fiber. The bottom waterproof layer is a waterproof breathable film, the proportion of polyester fiber in the health-care fabric is 35%~45%, the proportion of milk fiber is 55%~65%, and the flax fiber in the hygroscopic and antibacterial fabric The proportion of bamboo fiber is 55%~75%, and the proportion of bamboo fiber is 25%~45%. Through the above-mentioned method, a kind of infant urine-separating composite fabric protective pad pointed out by the present invention, the surface care layer is breathable and moisture-conducting, maintains the skin, the moisture absorption of the middle water storage layer is fast, the water absorption capacity is large, and the antibacterial property is good, and the bottom waterproof layer is in While ensuring waterproofness, it improves breathability.

Owner:TAICANG XINTAI KNITTING

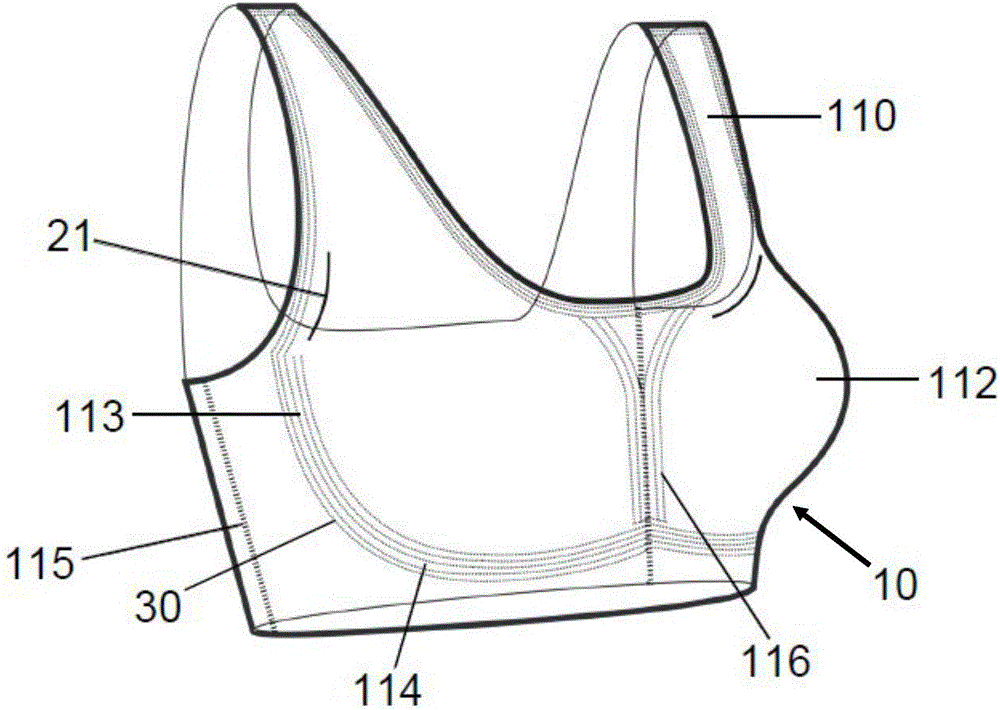

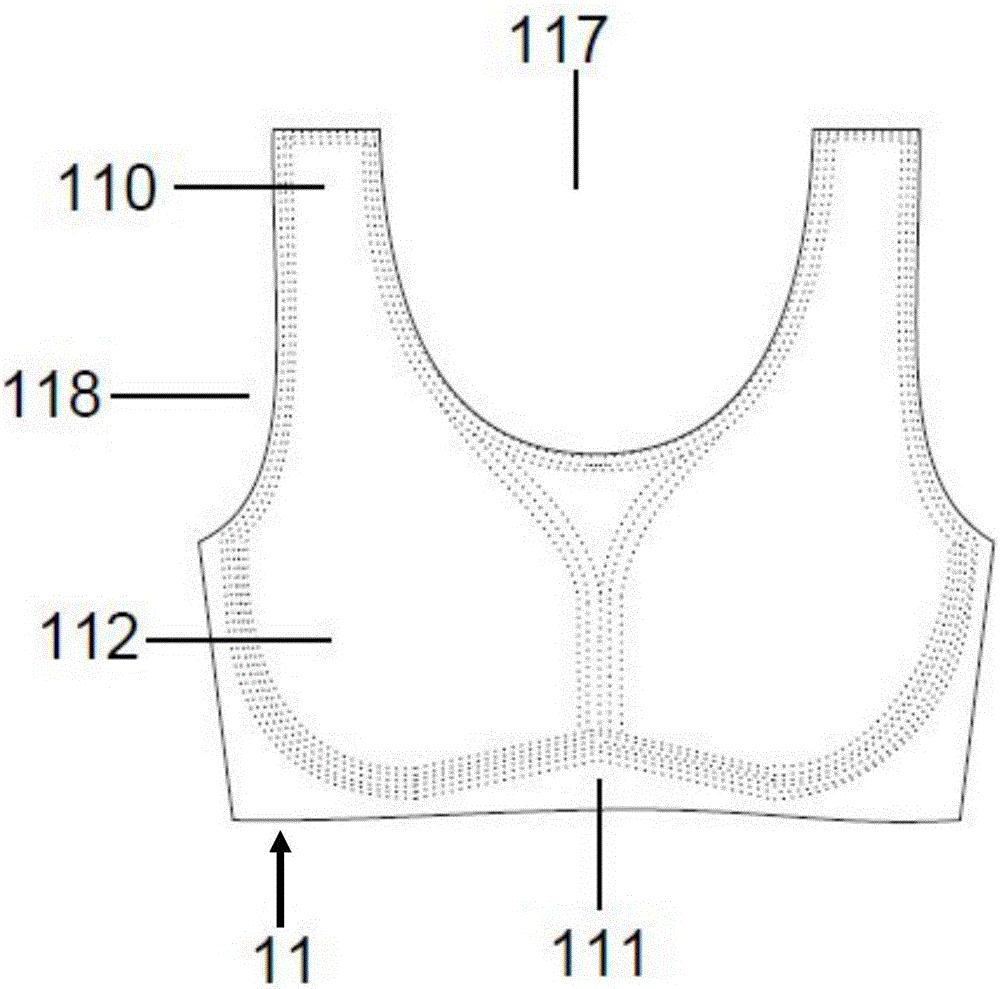

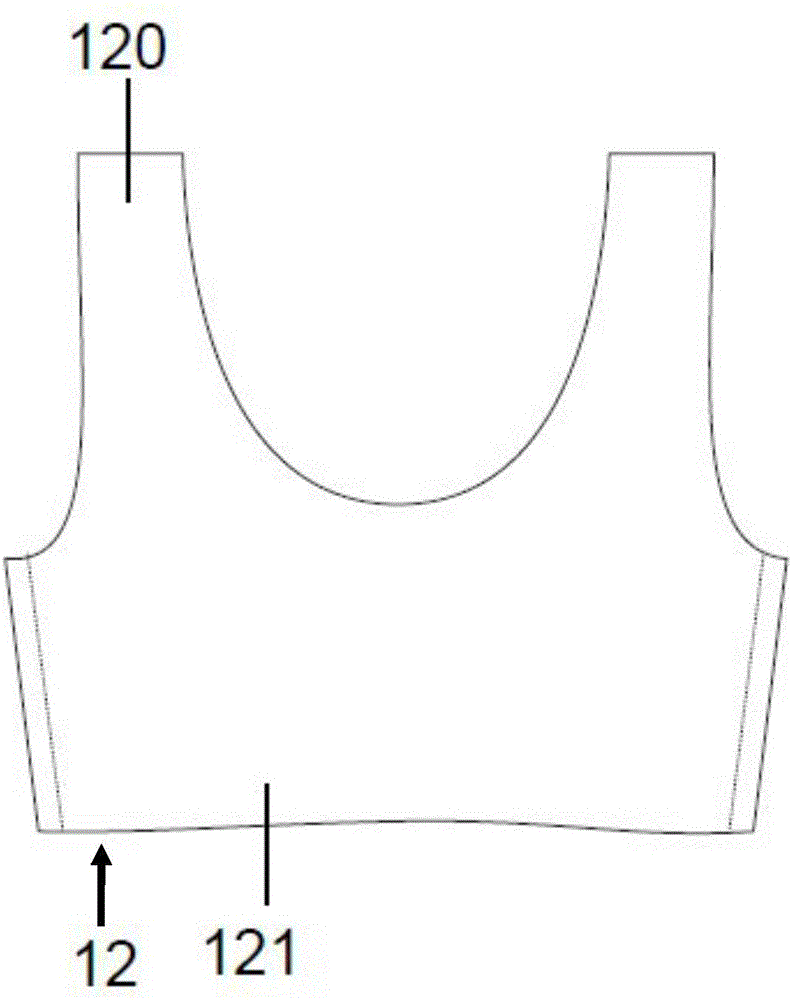

Free-cut bra and method of manufacturing the same

Owner:上海安蒂斯内衣服饰有限公司

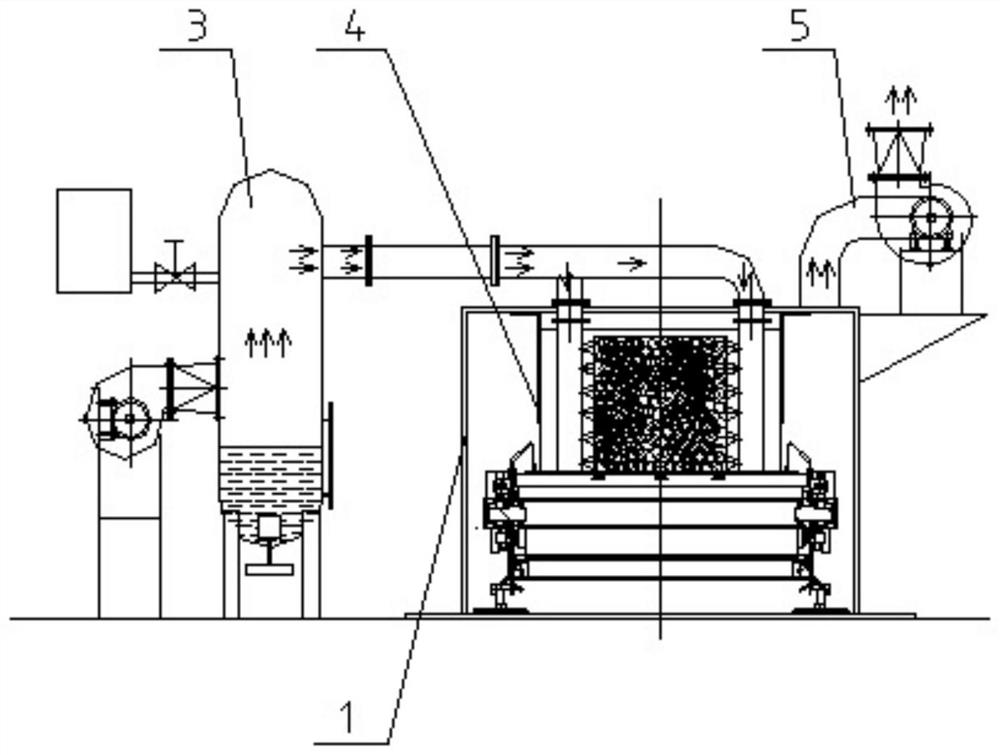

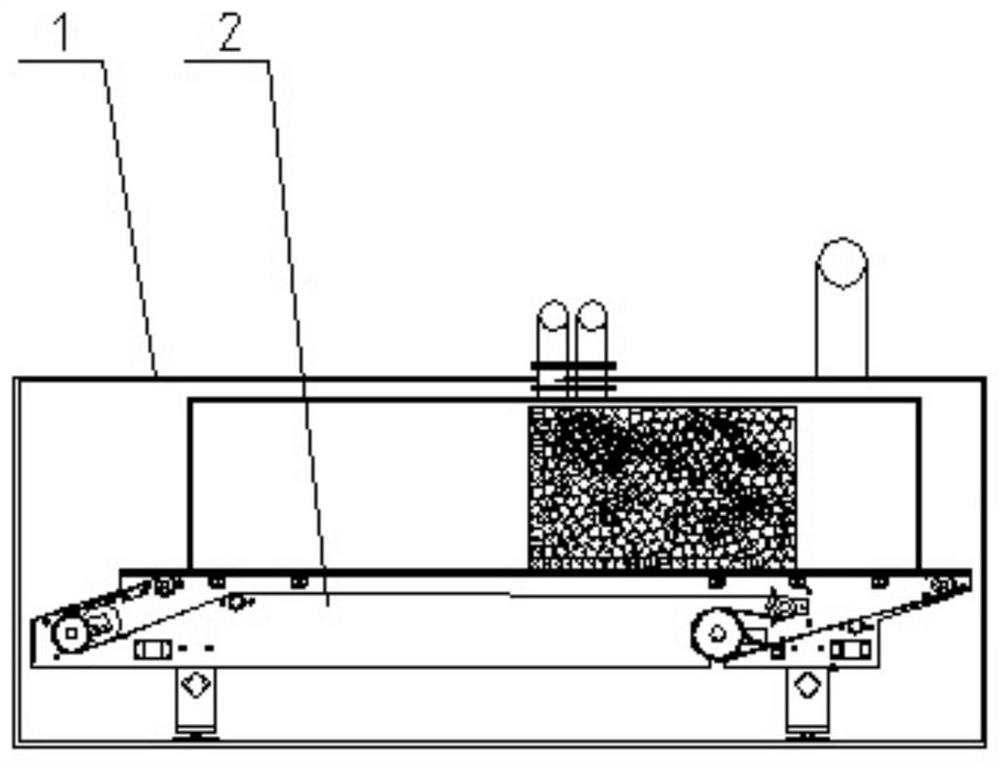

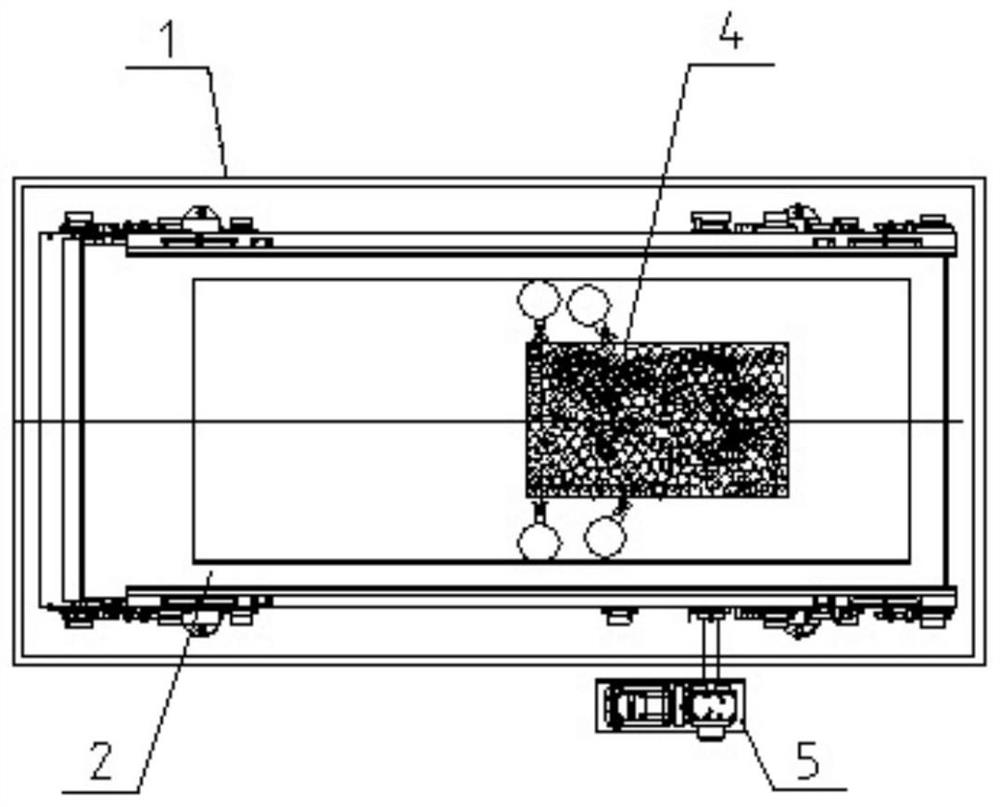

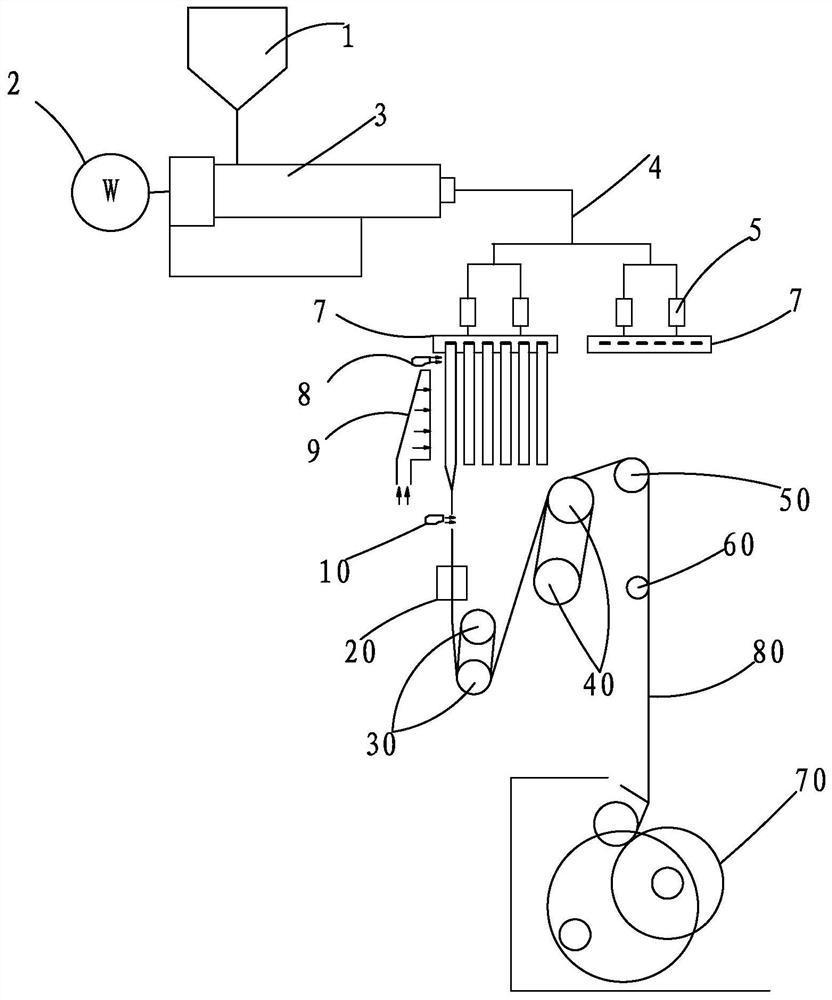

A device and method for loosening cigarette packs using ultrasonic humidification

ActiveCN111869916BMoisture absorption fastHeating up fastTobacco preparationEngineeringCigarette pack

The invention discloses a device and method for loosening cigarette packs by ultrasonic humidification, and belongs to the technical field of tobacco processing. It includes an outer cavity and a cigarette pack receiving device arranged in the outer cavity, an ultrasonic steam generator, and a humidification cavity, and the ultrasonic steam generator is used to generate liquid water mist; the humidification cavity is covered by the cigarette pack Above the pick-up device, two groups of nozzles are arranged in the humidification cavity, and the two groups of nozzles are respectively connected with the ultrasonic steam generator; the injection direction of one group of nozzles is the same as that of the cigarette pack, and the other group of nozzles The injection direction of the tube has an included angle with the layer of the cigarette pack. One group of nozzles repeatedly sprays steam on the cigarette pack along the layer direction, and the steam penetrates into the cigarette pack along the layer gap, and the other group of nozzles sprays to separate the layers of the cigarette pack after moisture absorption and heat up, and the separation between the smoke packs Finally, the steam enters the inside of the cigarette pack more easily, ensuring that the inner and outer leaves absorb moisture and heat up more evenly, so as to achieve the effect of loose cigarette packs.

Owner:ZHISI HLDG GRP

Siliceous copolymer resistor type thin film humidity sensitive element and method for making same

InactiveCN100385703CLower impedanceReduce volumeSolid-state devicesMaterial moisture contentDewCopolymer

This invention discloses a siliceous copolymer resistance thin film dew sensor and its process method, wherein the sensor comprises the following parts: micro crystal glass base with multiple pairs of crossed gold electrode connected with wires on the surface; dew sensitive film coated on the surface of the micro crystal glass and the crossed gold electrode, wherein the film is the siliceous positive ion electrolyte copolymer. The method comprises the following steps: a, dipping the micro crystal glass and the crossed gold electrode into the dew sensitive liquid by dipping machine; pulling and taking out the electrode for thermal process to make the dew sensitive film; b, electrifying the micro crystal glass with dew sensitive film and the electrode under certain temperature and the humidity to get the dew sensor.

Owner:上海华实纳米材料有限公司

Production process of a new type of nylon 6 with fdy flat cross-section

ActiveCN109440206BFeel softRich in three-dimensionalityMonocomponent copolyamides artificial filamentMelt spinning methodsWinding machineFiber

The present invention provides a kind of production technology of the polyamide fiber 6 of a kind of novel FDY matting flat section, step S1, add full matting slice in the silo; Step S2, slice enter screw extruder, extrude from the top of screw extruder; Step S3. After the melt is metered by the spinning metering pump, filtered, mixed and pressurized by the spinning assembly, a thin stream of the melt is sprayed from the spinneret hole, and then cooled and solidified to form; step S4, the formed primary fiber is processed Oiling operation; step S5, the primary fiber after oiling enters the pre-netting device, and under the action of a certain low air pressure, the tows are intertwined with each other; step S6, the primary fiber is first wound on the cold roll and then pulled in an orderly manner Winding and shaping on the hot roller; step S7, the fiber filaments are sent into the main network device, and the network is carried out; step S8, then winder is wound into a silk cake; the production process of the present invention is simple and efficient. High, high and stable product quality, can effectively meet the needs of the market, and has broad application prospects.

Owner:CHANGLE LIHENG POLYAMIDE TECH +1

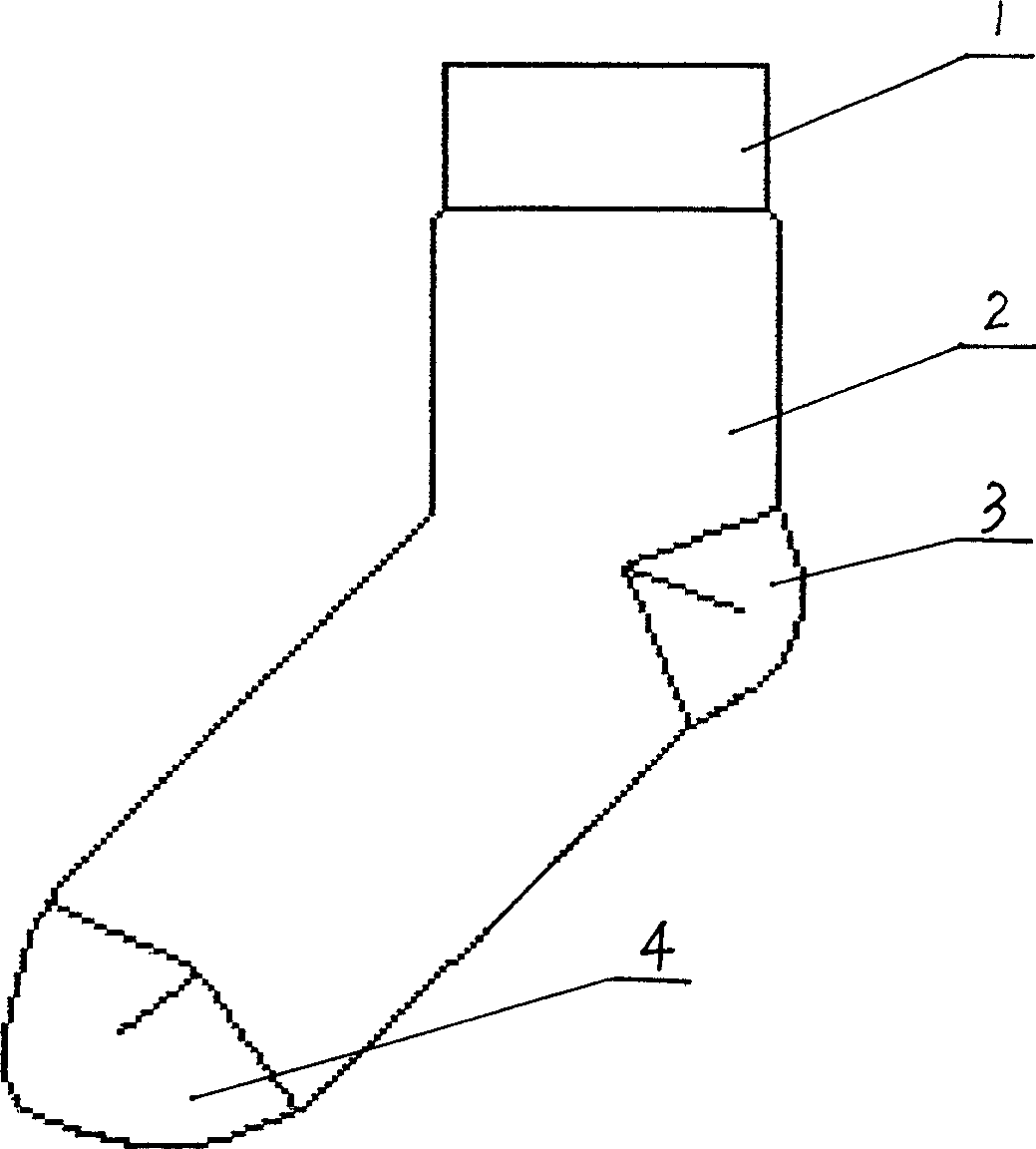

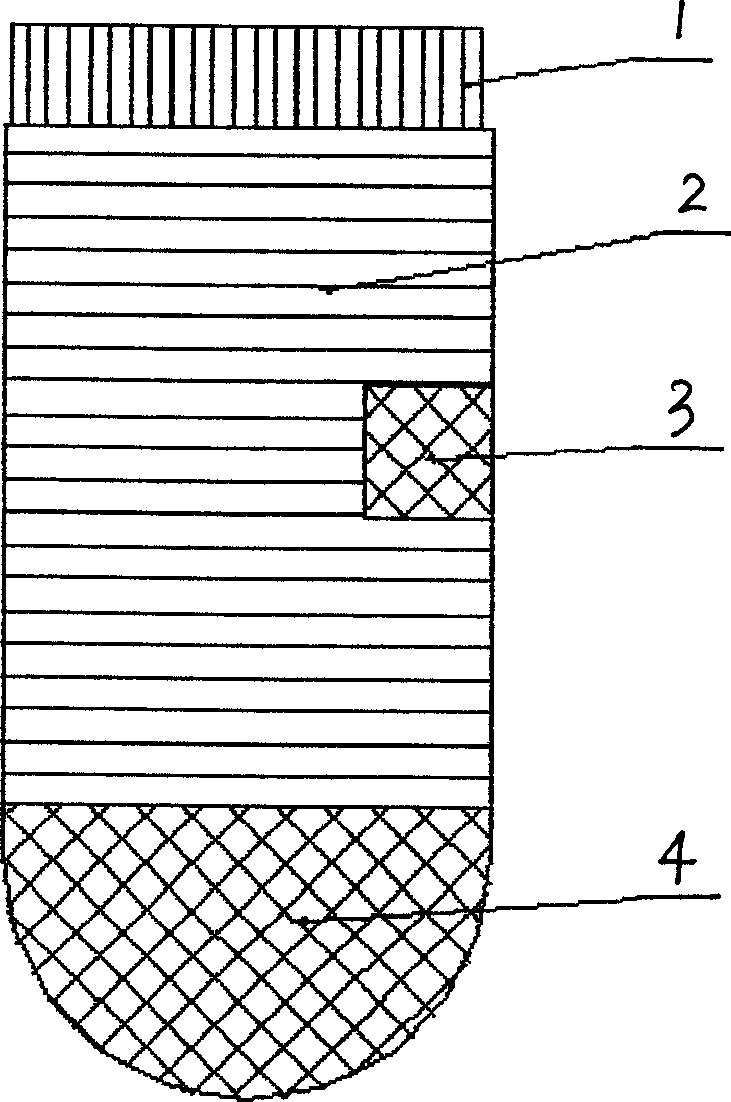

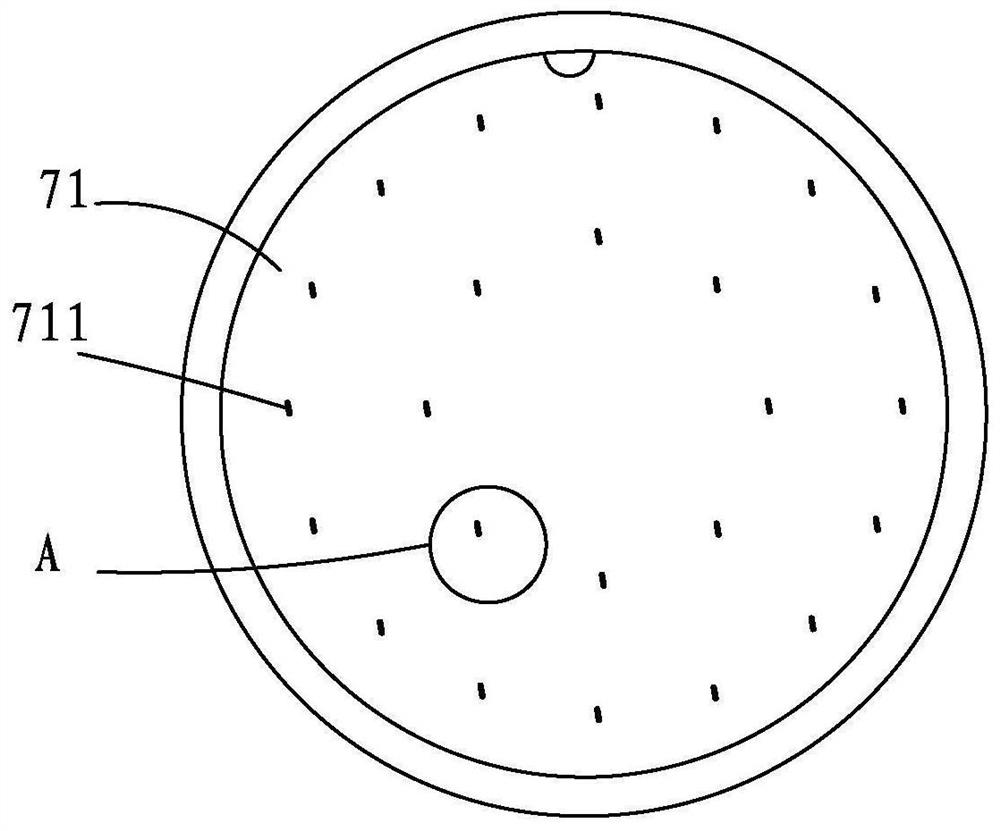

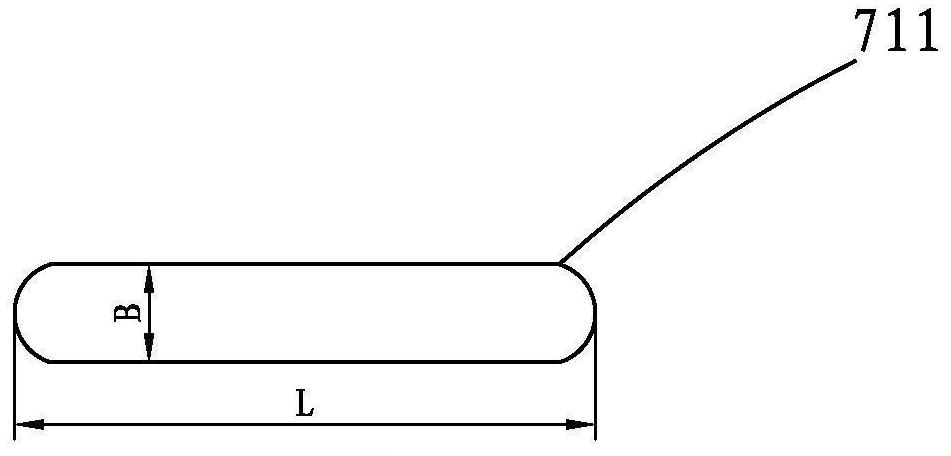

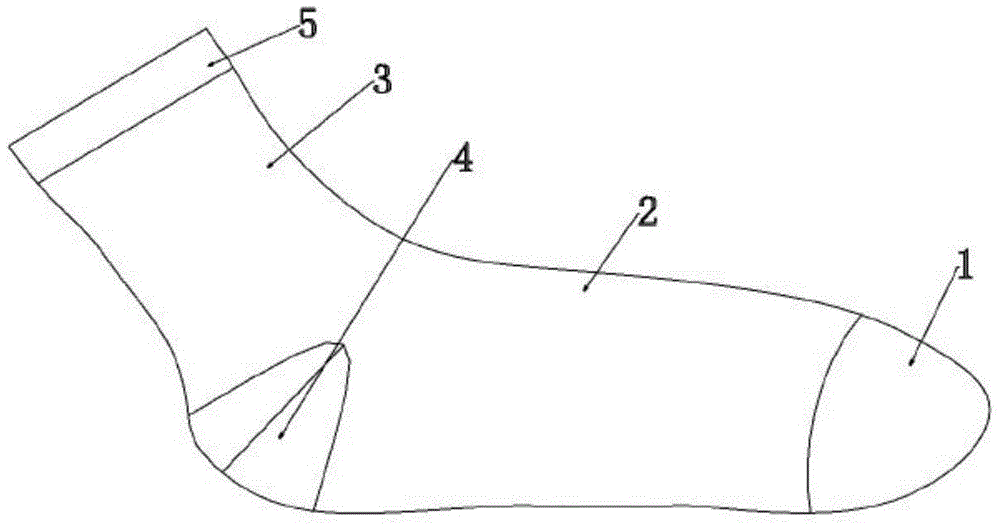

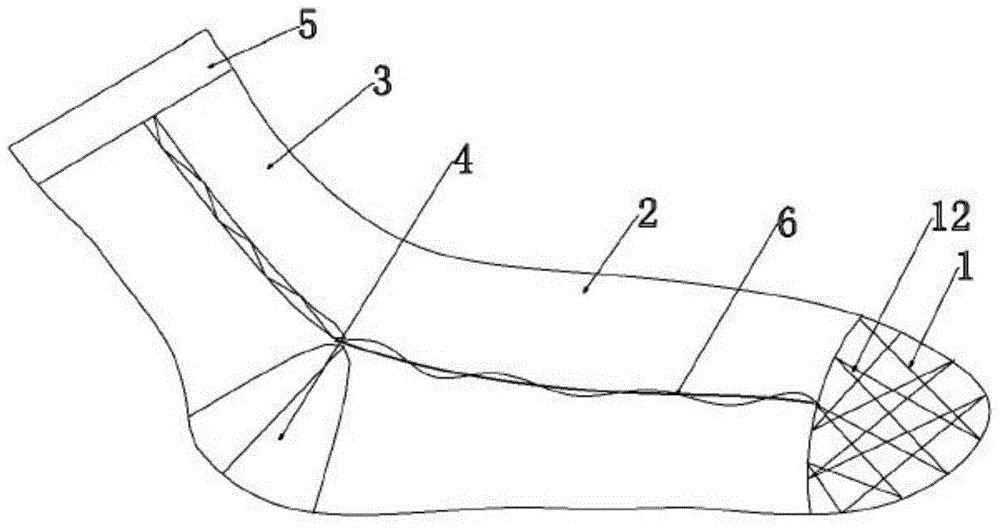

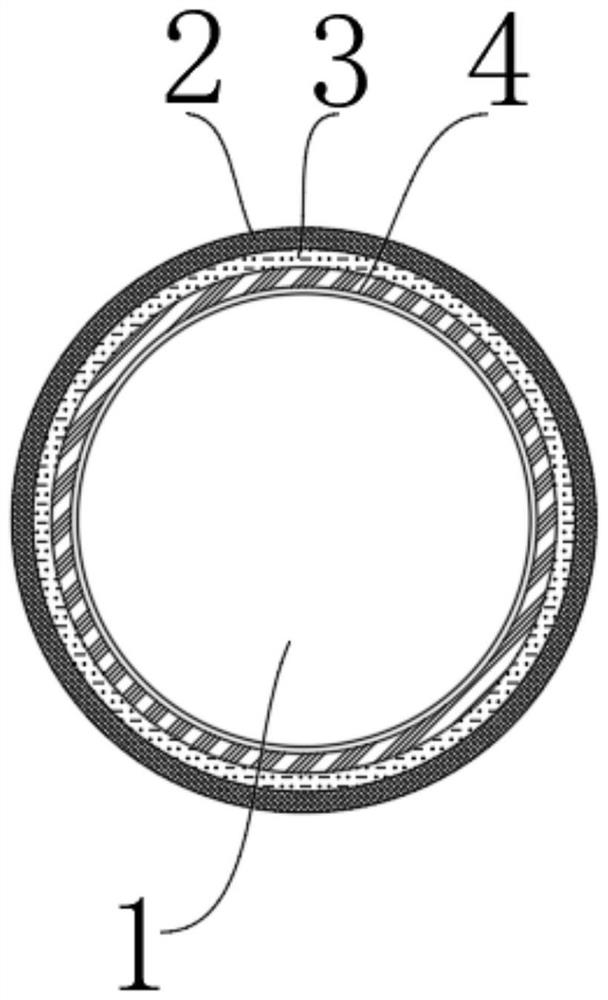

Health-care ramie socks and its weaving method

InactiveCN104041943BGood sweat absorption and breathabilityQuick dehumidificationSucessive textile treatmentsWeft knittingYarnEngineering

The invention discloses a health ramie sock and a waving method of the ramie sock, wherein the health ramie sock is good in breathability and sweat absorption capacity, and simple in the waving method. The sock comprises a sock palm sleeve, a sock leg sleeve, a sock head and a sock foot. The sock palm sleeve and the sock head at least comprise an elastic wrapping yarn layer and a ramie layer or a cotton- linen-mixing yarn layer. The sock leg sleeve and the sock foot comprise at least an elastic wrapping yarn layer and a combed cotton layer or a cotton- linen-mixing yarn layer, and the sock foot is provided with a health film layer. According to the method, the corresponding yarn processing, knitting sock processing and sock weaving are included, the yarn processing comprises softening of the ramie yarns, and the knitting sock processing comprises emulsion removing and leveling and shaping of the knitting sock and the forming of the health film layer in the sock foot of the knitting sock.

Owner:JIANGXI JINGZHU IND

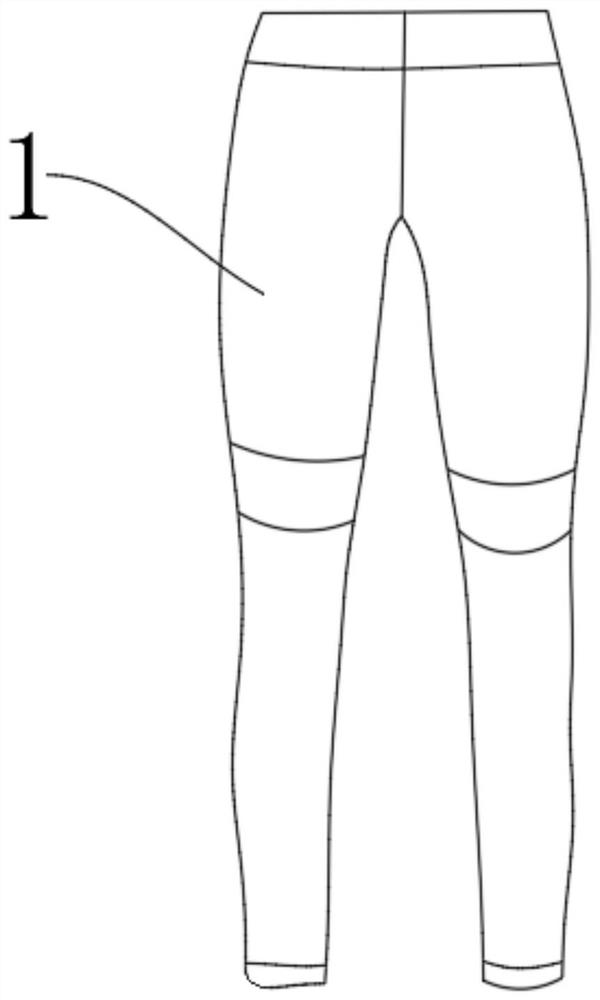

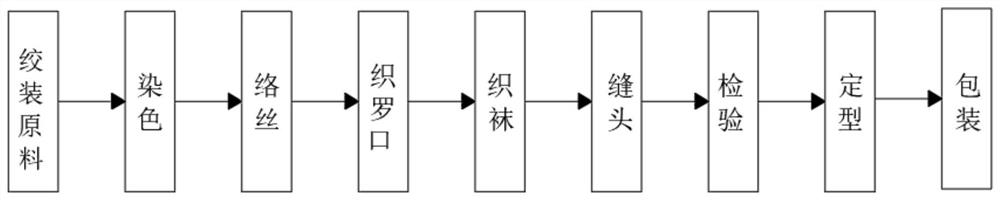

Production and manufacturing method of yoga pants with terahertz fibers

InactiveCN112401335AReduced blood flow resistance and blood viscosityImprove microcirculationTrousersClothes making applicancesPerspirationBlood flow

The invention discloses a production and manufacturing method of yoga pants with terahertz fibers. The yoga pants comprise a yoga pants main body, and the raw materials in the yoga pants main body arechinlon, spandex and terahertz fibers. The yoga pants body is produced and manufactured through the following steps of raw material twisting, dyeing, reeling, rib top weaving, sock weaving, end sewing, inspection, shaping and packaging. According to the invention, the pants have the characteristics of moisture removal, perspiration, breathability and quick drying, moisture absorption can be conducted quickly, a high-tech grinding technology is adopted, terahertz fibers are adopted in the yoga pants to promote blood circulation, the waist can be protected, uterus can be warmed, lasting and effective antibiosis and mite resistance are achieved, the immunity of the organism is improved, and terahertz can promote blood circulation, reduce blood vessel expansion, blood flow resistance and blood viscosity, improve microcirculation, increase oxygen storage and eliminate carbon dioxide after terahertz light waves permeate into a human body, and has a good effect of preventing and improving cardiovascular and cerebrovascular diseases.

Owner:义乌市完型科技有限公司

High molecular resistance type thin film humidity sensitive element with interpenetrating network structure and fabricating method thereof

InactiveCN1300575CLower impedanceReduce volumeMaterial resistanceMaterial electrochemical variablesTectorial membraneGlycidyl methacrylate

This invention discloses a macromolecule resistance film wet-sensitive element with mutual network structure and its process method. The wet-sensitive element is characterized by the micro-crystal glass base plate surface with eight to sixteen pairs of gold electrode and the coated wet-sensitive film and protective film. The wet-sensitive film has crosslinked (4-vinyl pyridine) and crosslinked (methacrylic acid compressed glyceride) to form mutual network structure.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com