Super thin spring socks and producing method

An ultra-thin, elastic stocking technology, applied in socks, pantyhose, clothing and other directions, can solve the problems of reduced thickness, unsuitable for hot summer wear, etc., to achieve the effect of not easy to break, wide application range, and fast moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific embodiment the present invention is described in further detail:

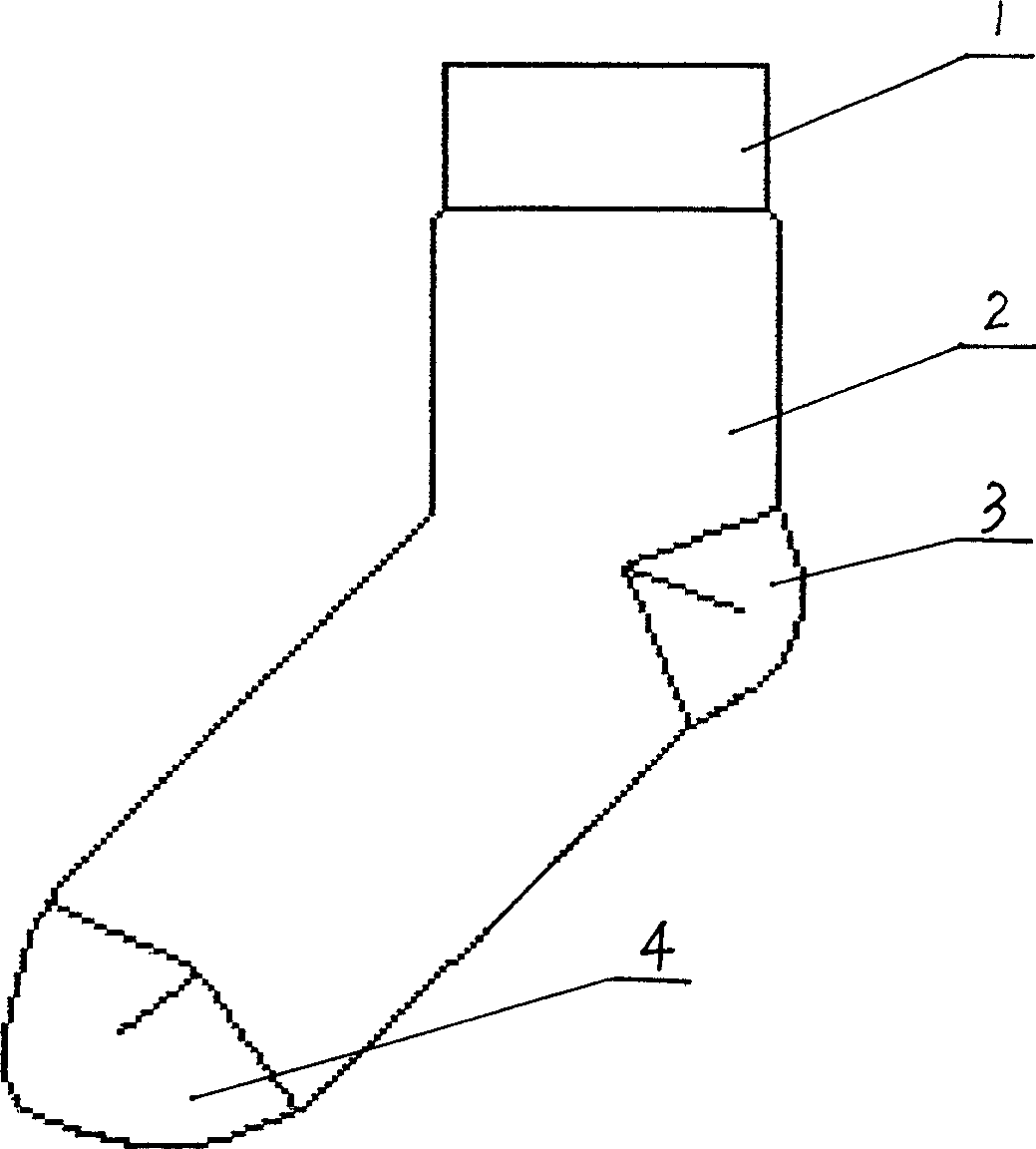

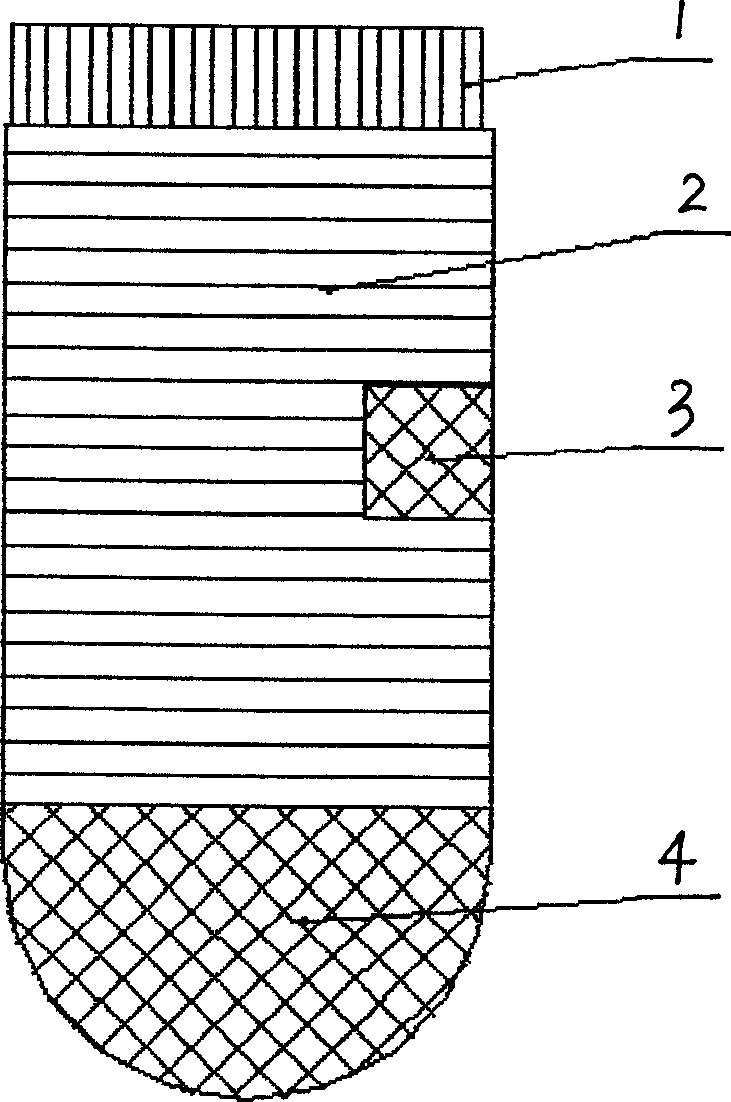

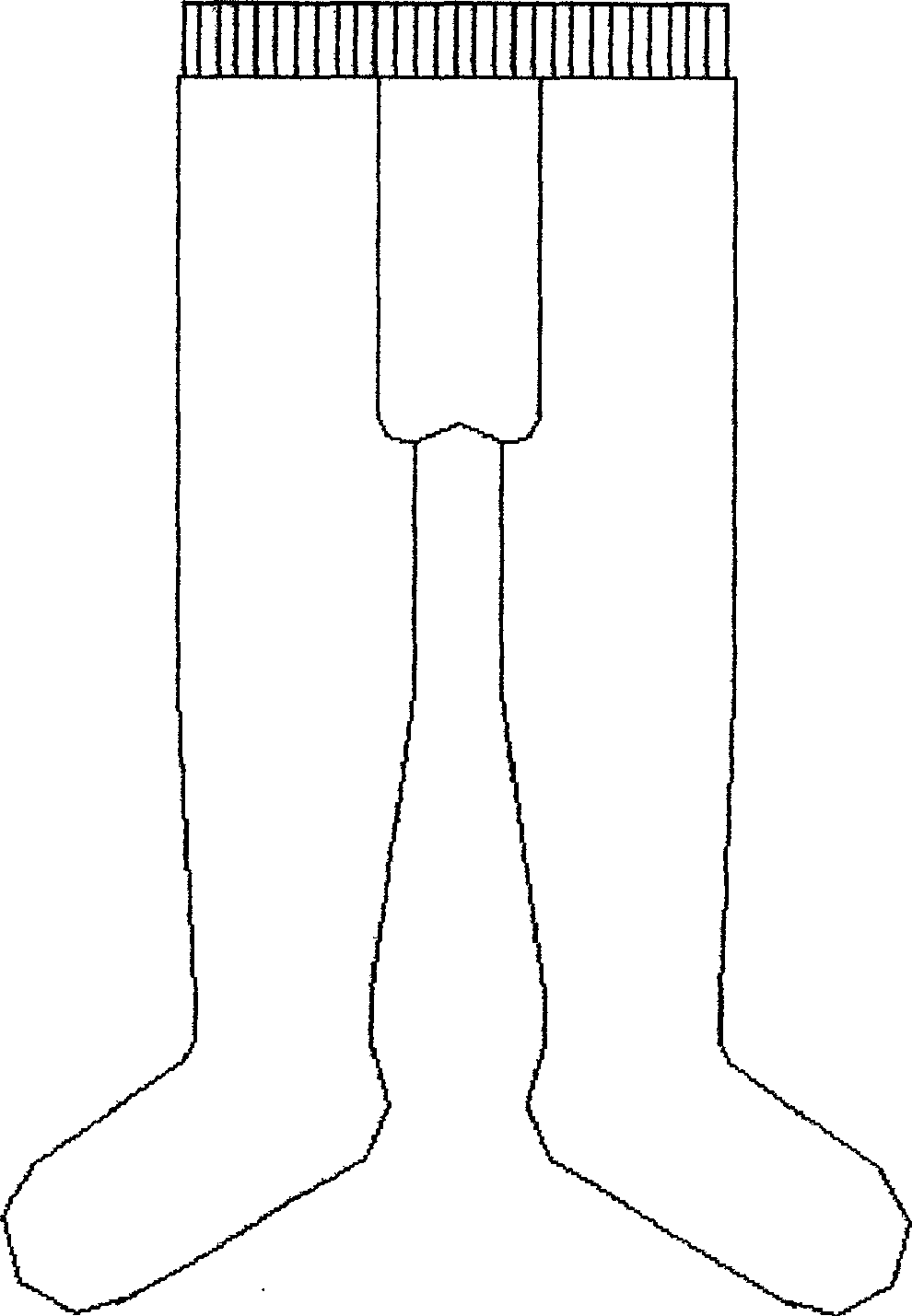

[0018] Product of the present invention is produced on silk stocking machine: as figure 1 or as figure 2 Shown: Cuff 1 is woven with 100% nylon and spandex, of course, it can also be woven with mercerized cotton and spandex.

[0019] The sock body 2 is woven with four-way yarn feeding, feeding 20 / 12 spandex nylon covered yarn in two symmetrical ways (yarn way 1 and 3), and feeding 60S / 2 mercerized cotton. In fact, one path is made of ultra-fine denier elastic fiber, and the adjacent yarn path is 60S / 2 mercerized cotton, which goes round and round and weaves in a spiral shape. When knitting the sock body, it is also necessary to consider the change of the number of needles, because 60S / 2 is relatively thick on a 400N stocking machine, and the socks will be thicker. 400N can be considered to be halved to 200N evenly. Implemented on the stockings machine, so as to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com