Core-sheath composite yarn and preparation method thereof

A technology of composite yarn and core-sheath type, which is applied in the direction of yarn, spinning machine, open-end spinning machine, etc., can solve the problems of low yarn forming efficiency and poor quality of composite yarn, and achieve the effect of improving yarn forming efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

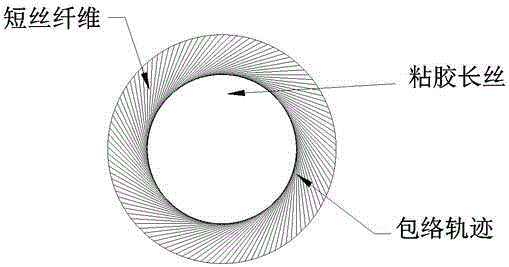

[0039] A core-sheath composite yarn, the core-sheath composite yarn is formed by enveloping staple fibers and viscose filaments, wherein the staple fibers are enveloped raw materials, viscose filaments are yarn cores, and The staple fiber is 0.8d, and the viscose filament is 120d.

[0040] Further, the core-sheath composite yarn is a monofilament core.

[0041] Further, the short filament fibers are bamboo charcoal fibers.

[0042] A method for preparing a core-sheath type composite yarn, comprising the steps of:

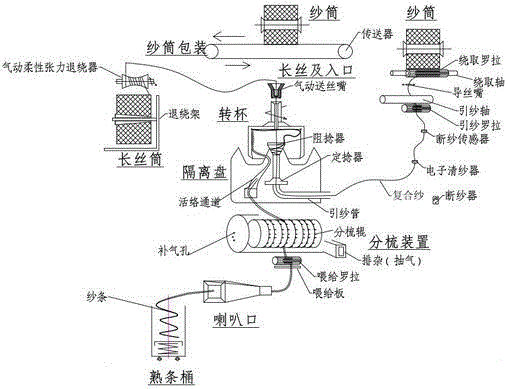

[0043] A. Viscose filament feeding

[0044] Put the viscose filament on the unwinding frame, and then under the action of the pneumatic flexible tension unwinder, the viscose filament is unwound 10 times in the direction of winding, and the unwound viscose filament is then passed through the pneumatic Wire feed nozzle, into the rotor;

[0045] B. Short fiber wire feeding

[0046]The short silk fibers stored in the cans pass through the bell mouth, the feeding p...

Embodiment 2

[0056] A core-sheath composite yarn, the core-sheath composite yarn is formed by enveloping staple fibers and viscose filaments, wherein the staple fibers are enveloped raw materials, viscose filaments are yarn cores, and The staple fiber is 1.2d, and the viscose filament is 300d.

[0057] Further, the core-sheath composite yarn is a double-filament core.

[0058] Further, the short filament fibers are cellulose fibers.

[0059] A method for preparing a core-sheath type composite yarn, comprising the steps of:

[0060] A. Viscose filament feeding

[0061] Put the viscose filament on the unwinding frame, and then under the action of the pneumatic flexible tension unwinder, the viscose filament is unwound 12 times in the direction of winding, and the unwound viscose filament is then passed through the pneumatic Wire feed nozzle, into the rotor;

[0062] B. Short fiber wire feeding

[0063] The short silk fibers stored in the cans pass through the bell mouth, the feeding pla...

Embodiment 3

[0075] A core-sheath composite yarn, the core-sheath composite yarn is formed by enveloping staple fibers and viscose filaments, wherein the staple fibers are enveloped raw materials, viscose filaments are yarn cores, and The staple fiber is 1.2d, and the viscose filament is 120d.

[0076] Further, the core-sheath composite yarn is a double-filament core.

[0077] Further, the short filament fibers are bamboo charcoal fibers.

[0078] A method for preparing a core-sheath type composite yarn, comprising the steps of:

[0079] A. Viscose filament feeding

[0080] Put the viscose filament on the unwinding frame, and then under the action of the pneumatic flexible tension unwinder, the viscose filament is unwound 11 times in the direction of winding, and the unwound viscose filament is then passed through the pneumatic Wire feed nozzle, into the rotor;

[0081] B. Short fiber wire feeding

[0082] The short silk fibers stored in the cans pass through the bell mouth, the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com