Ultra-coarse denier flat shredded and method for making same

A technology of flat yarn and ultra-coarse denier, which is applied in filament/thread forming, textile and papermaking, fiber treatment, etc. It can solve the problems of increased yarn twist and prolonged reaction time, etc., and achieves smooth, elastic and soft fabric. , rich in three-dimensional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

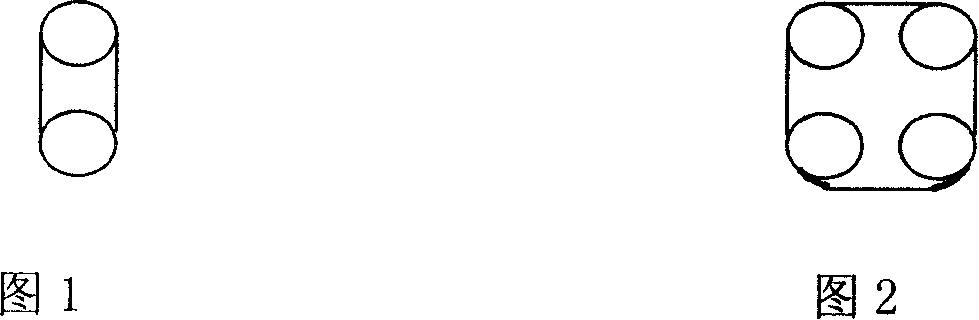

Image

Examples

Embodiment 1

[0035] The preparation of embodiment 1 1200D / 20F ultra-coarse denier flat yarn

[0036] a. Prepare color paste;

[0037] The described process of preparing color paste is:

[0038] (1) Titanium dioxide preparation: take 50kg of titanium dioxide, use 450kg of soft water, and prepare through dilution, stirring, mixing, grinding and filtration;

[0039] (2) Preparation of mixed slurry: take 70kg of titanium white solution prepared in step a, mix it with 10kg of color paste in a mass ratio of 7:1, grind and filter it; the ratio can be adjusted according to the color requirements; the filtration pressure is 2 .

[0040] (3) Dilute mixed slurry: Dilute the 80kg mixed slurry in step b with 80kg soft water, mix and stir evenly.

[0041] b. Take the recovered glue for deep aging, the aging time is 12 hours, the aging degree is 8.5ml; defoaming; the defoaming time in step b is 8 hours; the vacuum degree of defoaming is 100mbar.

Embodiment 2

[0044] The preparation of embodiment 2 600D / 10F ultra-coarse denier flat yarn

[0045] a. Prepare color paste;

[0046] The described process of preparing color paste is:

[0047] (1) Titanium dioxide preparation: take 50kg of titanium dioxide, use 250kg of soft water, and prepare through dilution, stirring, mixing, grinding and filtration;

[0048] (2) Preparation of mixed slurry: take 70kg of titanium white solution prepared in step a, mix it with 10kg of color paste in a mass ratio of 7:1, grind and filter it; the ratio can be adjusted according to the color requirements; the filtration pressure is 2 .

[0049] (3) Dilute mixed slurry: Dilute the 80kg mixed slurry in step b with 80kg soft water, mix and stir evenly.

[0050] b. Take the recovered glue for deep aging, the aging time is 12 hours, the aging degree is 8.0ml; defoaming; the defoaming time in step b is 8 hours; the vacuum degree of defoaming is 120mbar.

Embodiment 3

[0053] Embodiment 3 Preparation of 1200D / 10F ultra-coarse denier flat yarn

[0054] a. Prepare color paste;

[0055] The described process of preparing color paste is:

[0056] (1) Titanium dioxide preparation: take 50kg of titanium dioxide, use 500kg of soft water, and prepare through dilution, stirring, mixing, grinding and filtration;

[0057] (2) Preparation of mixed slurry: take 70kg of titanium white solution prepared in step a, mix it with 10kg of color paste in a mass ratio of 7:1, grind and filter it; the ratio can be adjusted according to the color requirements; the filtration pressure is 2 .

[0058] (3) Dilute mixed slurry: the 80kg mixed slurry of step b is diluted with 400kg soft water, mixed and stirred evenly.

[0059] b. Take the recovered glue for deep aging, the aging time is 15 hours, the aging degree is 8.0±1.0m1; defoaming; the defoaming time in step b is 10 hours; the vacuum degree of defoaming is 120mbar.

[0060] c. Using an acid bath system, spinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dimension | aaaaa | aaaaa |

| dimension | aaaaa | aaaaa |

| dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com