Special high-elasticity yarn and fabric thereof

A high-elastic yarn and high-elastic technology, applied in the direction of yarn, textile, fabric, etc., can solve the problems of unsatisfactory performance of polyester fiber yarn, poor elastic recovery, poor moisture absorption and perspiration performance, etc., to improve moisture absorption and quick drying Good performance, elastic recovery, dry and soft touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

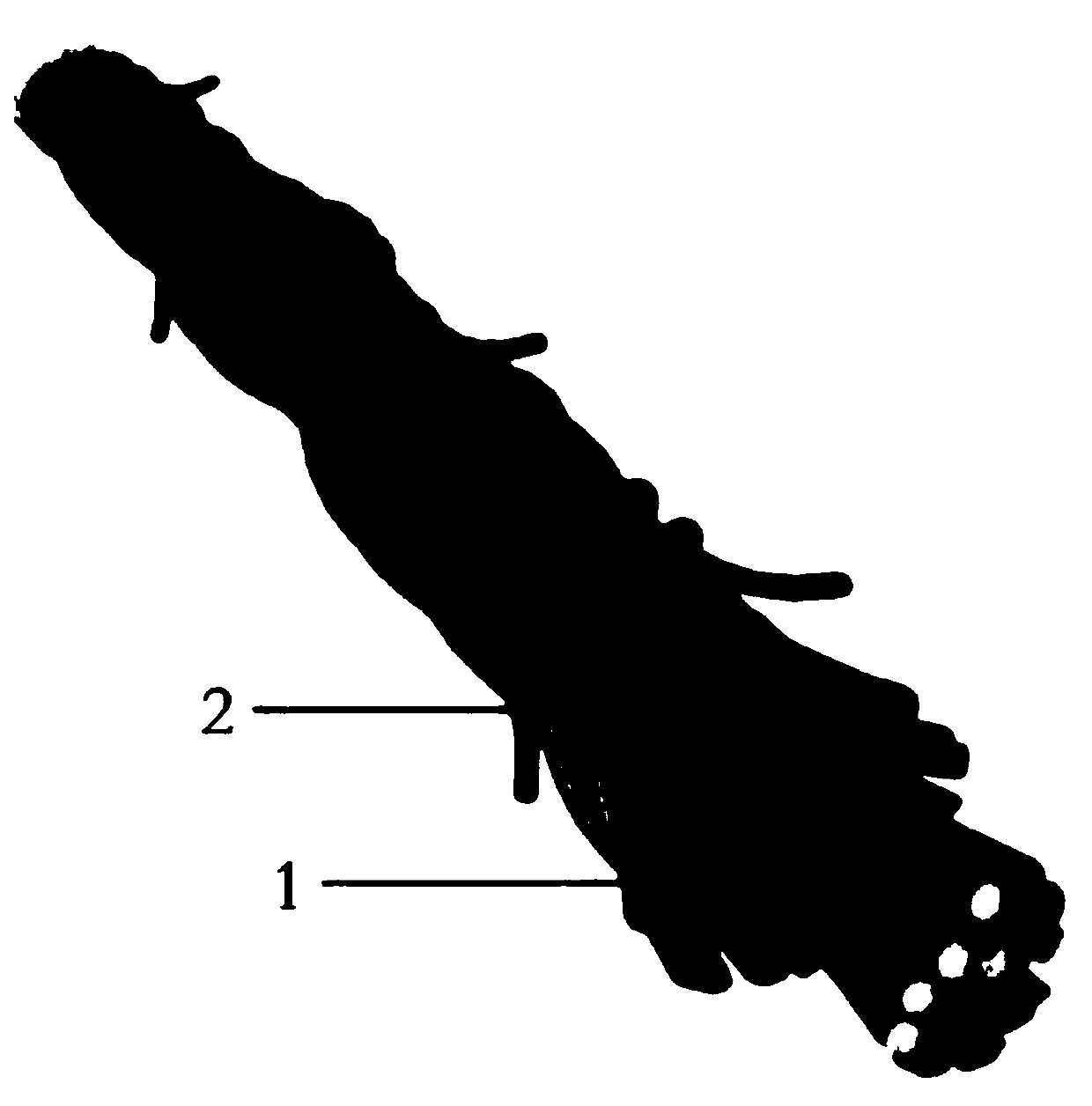

[0020] combine figure 1 , the invention discloses a special high-elastic yarn, which includes an outer covering fiber 2 and a core yarn 1 . The outer covering fiber 2 is spirally wrapped outside the core yarn 1 . The outer covering fiber 2 is a high-elastic composite yarn. The core yarn 1 is a PTT filament. In the invention, the high-elastic composite yarn and the PPT filament are passed through a sheath-core structure to realize synergistic promotion and improve the overall performance of the yarn. The high-elastic composite yarn mainly exhibits the soft and elastic touch and moisture absorption and moisture-conducting properties of the special high-elastic yarn, while the PTT filament mainly optimizes the structural strength and elastic recovery of the special high-elastic yarn. combine figure 2 , the high-elastic composite yarn is a bicomponent composite yarn made of PBT and PET through twin-screw spinning machine conjugate spinning. The mass ratio of PBT and PET in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com