High molecular resistance type thin film humidity sensitive element with interpenetrating network structure and fabricating method thereof

A technology of interpenetrating network structure and humidity sensor, which is applied in the field of polymer resistive film humidity sensor, can solve the problems of difficult to measure low humidity environment, poor resistance to high humidity environment, low response sensitivity, etc., and achieve fast moisture absorption and desorption Wet response speed, strong ability to withstand high humidity environment, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

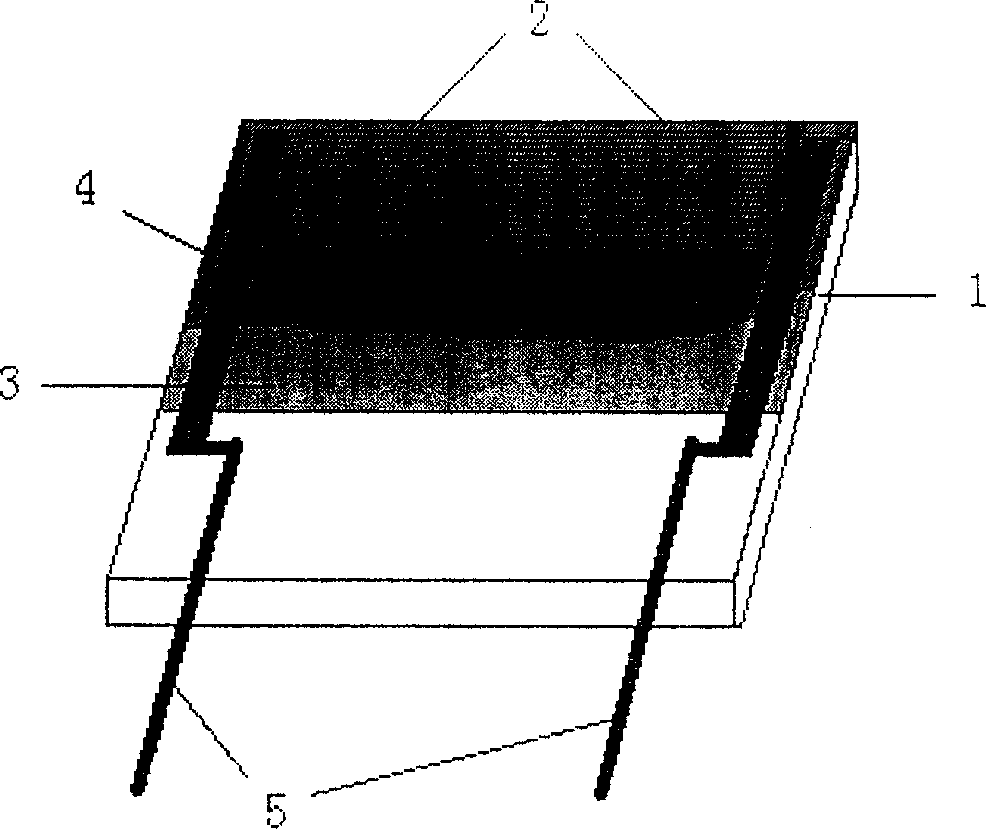

[0023] The preparation method of the moisture-sensitive film is as follows: use a dipping machine to immerse the microcrystalline glass interdigitated gold electrode in the moisture-sensitive liquid, after pulling and taking it out, carry out quaternization at 80-120°C and simultaneously cross-link for 1-15 Hours, a moisture-sensitive film with an interpenetrating network structure was obtained.

[0024] The components of the moisture-sensitive liquid are calculated by weight percentage: 2-5% for polymer, 1-25% for dibromobutane, 0.5-3% for diethylenetriamine, and 70-96% for dimethyl sulfoxide , wherein in the polymer, poly(4-vinylpyridine):poly(glycidyl methacrylate)=1:2-4.

[0025] The preparation method of the protective film is as follows: use a dipping machine to immerse the glass-ceramic interdigitated gold electrode with a moisture-sensitive film in an ethylcellulose absolute ethanol solution with a concentration of 0.5% to 1% by weight, and pull, After taking it out, ...

Embodiment 1

[0028] 1) Coating to prepare moisture-sensitive film and quaternization cross-linking reaction

[0029] Dip the glass-ceramic interdigitated gold electrode into the moisture-sensitive liquid with a dipping machine, pull it up and take it out, then carry out quaternization and cross-linking reaction at 80°C for 15 hours. Each component of the moisture-sensitive liquid is calculated by weight percent: the polymer is 2.5% (poly(4-vinylpyridine): poly(glycidyl methacrylate)=4:1); dibromobutane is 2%; Diethylenetriamine is 0.5%; dimethyl sulfoxide is 95%.

[0030] 2) Preparation of protective film and post-treatment by dip coating

[0031] Use a dipping machine to immerse the glass-ceramic interdigitated gold electrode with a moisture-sensitive film in an ethylcellulose absolute ethanol solution (0.1% by weight), pull it, take it out, and heat-treat it at 70°C for 40 minutes ;

[0032] 3) Aging treatment

[0033] Put the humidity sensitive element with moisture sensitive film a...

Embodiment 2

[0035] 1) Preparation of moisture-sensitive film by dip coating and quaternization crosslinking reaction

[0036] Dip the glass-ceramic interdigitated gold electrode into the moisture-sensitive solution by using a dipping machine, pull it up and take it out, then perform quaternization and simultaneous cross-linking reaction at 90°C for 5 hours. Each component of the moisture-sensitive liquid is calculated by weight percent: the polymer is 5% (poly(4-vinylpyridine):poly(glycidyl methacrylate)=1:1); dibromobutane is 23%; Diethylenetriamine is 2%; dimethyl sulfoxide is 70%.

[0037] 2) Preparation of protective film and post-treatment by dip coating

[0038] Use a dipping machine to immerse the glass-ceramic interdigitated gold electrode with a moisture-sensitive film in an ethyl cellulose absolute ethanol solution (1% by weight), pull it up, take it out, and heat-treat it at 85°C for 20 minutes ;

[0039] 3) Aging treatment

[0040] Put the humidity sensitive element with m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com