Production process of a new type of nylon 6 with fdy flat cross-section

A production process and extinction technology, applied in the field of spinning manufacturing, can solve the problems that the performance indicators cannot meet the requirements, no market competitiveness, different performance, etc., to improve market competitiveness, product quality and stability, and production technology. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

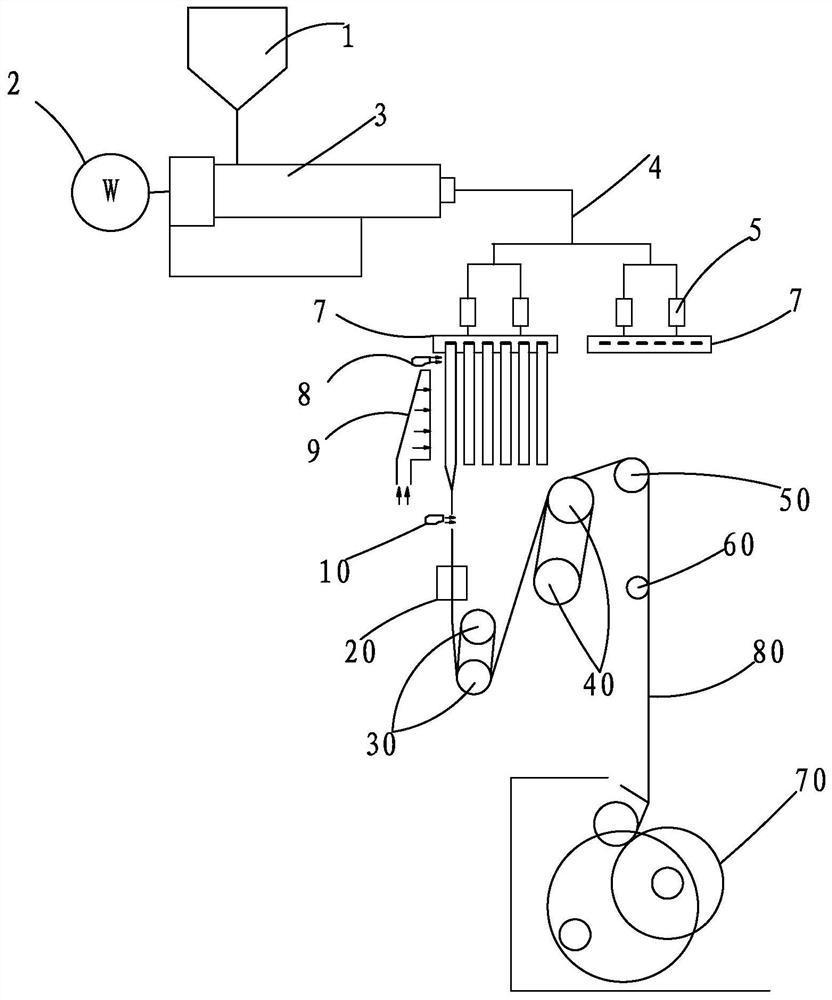

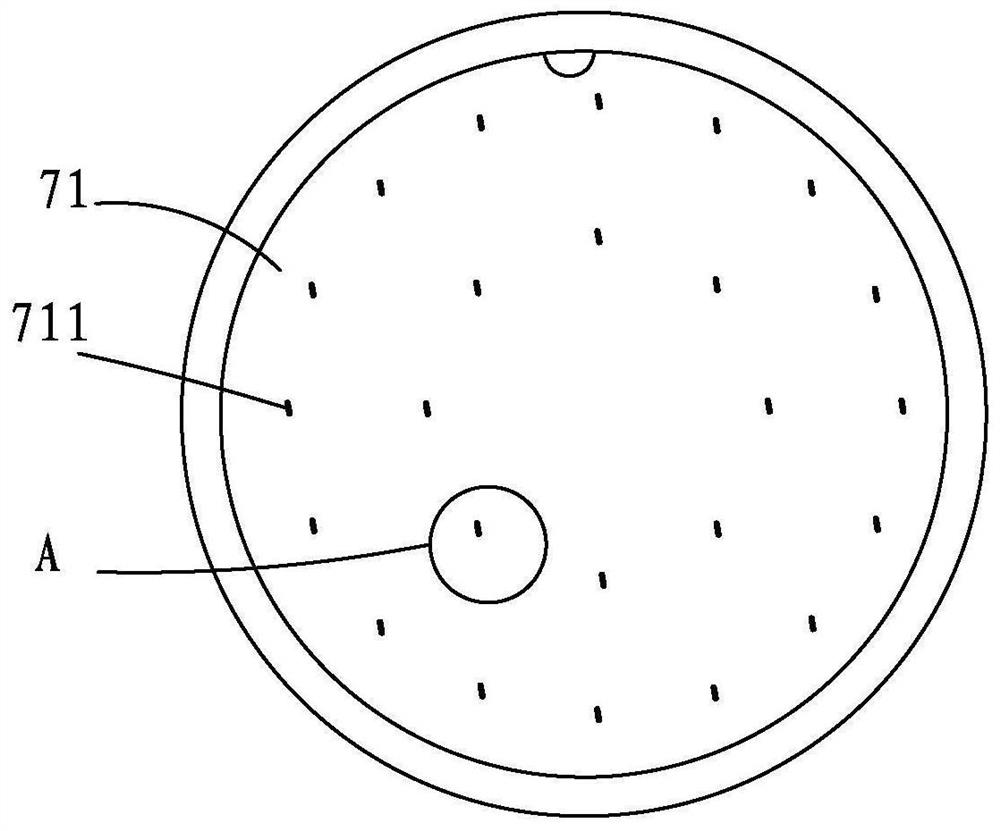

[0032] see Figures 1 to 4 As shown, the reference number of the present invention does not use "6" to avoid confusion with the number in the nylon 6, while the reference number "80" is nylon 6 to avoid confusion, and there is no label behind the nylon 6 80.

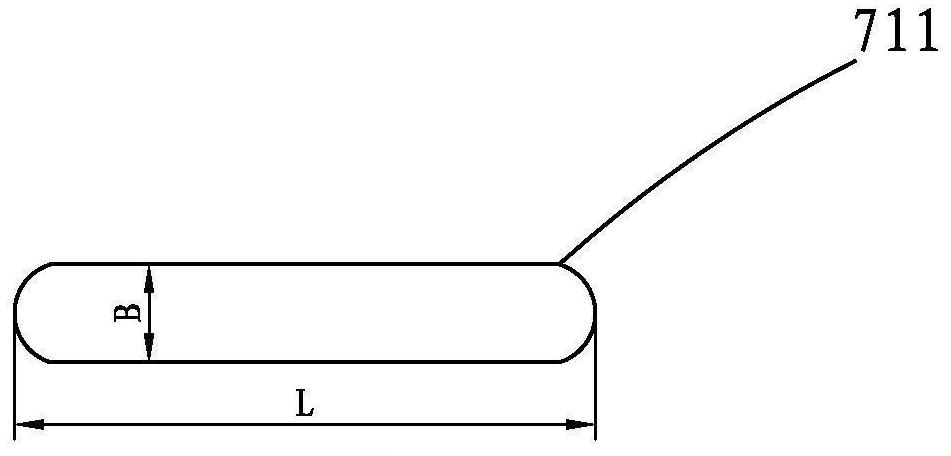

[0033] The invention provides a new type of nylon 6 with FDY matte flat section. The cross section of the nylon 6 is "one" shape, and the two ends of the cross section are arc transitions, so as to form a new filament.

[0034] The nylon 6 has a linear density of 40.6 dtex / F, a breaking strength of 4.59 CN / dtex, a breaking elongation of 48%, a boiling water shrinkage of 9.8%, an oil content of 1.6%, and an unevenness of evenness of 1.33%. , the network is 6 pieces / meter, and the dyeing is controlled at 5.0 grades. When these performance parameters of the nylon 6 of the present invention are satisfied at the same time, the performance is better, and the market value is high, so that the nylon 6 of the present invention h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com