Production method of bastose wet spinning yarn

A production method and hemp fiber technology are applied in the production field of hemp fiber wet-spun colored yarns, which can solve the problems of dull appearance of finished products, poor yarn quality, serious sticking of hemp sliver, etc., and meet the requirements of soft hand and color. , The finished product has good color fastness, rich and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

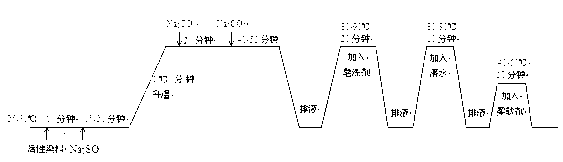

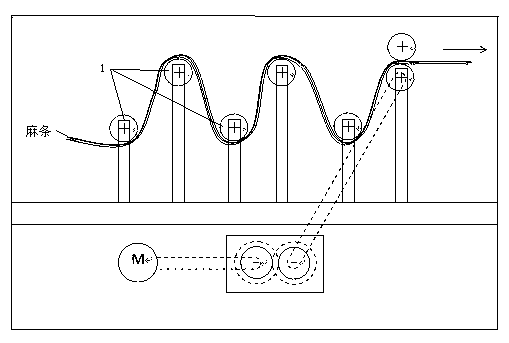

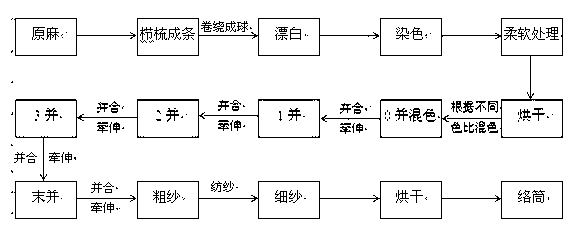

[0021] see figure 1 , figure 2 , Comb the raw hemp. The combing includes two processes of sliver making and balling. The sliver making is to remove the short fibers in the raw hemp, and then make the long hemp fibers into hemp sliver, and then pass through the traverse on the hemp ball winding machine. The feeding device winds the continuous hemp strips layer by layer from the inside to the outside to the winding roller to form a hollow cylindrical hemp ball with uniform inner and outer density. The inner diameter of the hemp ball is 5-10cm, the outer diameter is 35-45cm, and the height of the ball is 30- 40cm. Bleaching is carried out after the hemp ball is degummed, and the bleaching includes two steps of sub-bleaching and low-temperature oxygen bleaching: first add 1.5g / L sodium chlorite NaClO in water 2 , the pH value is 2.5-3.5, the initial temperature is 30°C, and it takes 30 minutes to raise the temperature to 50°C, keep warm for 20 minutes, and then wash with water ...

Embodiment 2

[0023] see figure 1 , figure 2 , Comb the raw hemp. The combing includes two processes of sliver making and balling. The sliver making is to remove the short fibers in the raw hemp, and then make the long hemp fibers into hemp sliver, and then pass through the traverse on the hemp ball winding machine. The feeding device winds the continuous hemp strips layer by layer from the inside to the outside to the winding roller to form a hollow cylindrical hemp ball with uniform inner and outer density. The inner diameter of the hemp ball is 5-10cm, the outer diameter is 35-45cm, and the height of the ball is 30- 40cm. Bleaching is carried out after the hemp balls are degummed, and the bleaching includes two steps of sub-bleaching and low-temperature oxygen bleaching: now add 1g / L sodium chlorite NaClO to the water 2 , the pH value is 2.5-3.5, the initial temperature is 30°C, and it takes 30 minutes to raise the temperature to 50°C, keep warm for 20 minutes, and then wash with wate...

Embodiment 3

[0025] see figure 1 , figure 2 , Comb the raw hemp. The combing includes two processes of sliver making and balling. The sliver making is to remove the short fibers in the raw hemp, and then make the long hemp fibers into hemp sliver, and then pass through the traverse on the hemp ball winding machine. The feeding device winds the continuous hemp strips layer by layer from the inside to the outside to the winding roller to form a hollow cylindrical hemp ball with uniform inner and outer density. The inner diameter of the hemp ball is 5-10cm, the outer diameter is 35-45cm, and the height of the ball is 30- 40cm. Bleaching is carried out after the hemp ball is degummed, and the bleaching includes two steps of sub-bleaching and low-temperature oxygen bleaching: now add 2g / L sodium chlorite NaClO to the water 2 , the pH value is 2.5-3.5, the initial temperature is 30°C, and it takes 30 minutes to raise the temperature to 50°C, keep warm for 20 minutes, and then wash with water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com