Manufacturing method of central tube FTTH enhanced type leading-in optical cable and optical cable

A technology that introduces optical cables and manufacturing methods, applied in the field of optical cable production, can solve problems such as not being suitable for indoor use, not considering water resistance, poor flexibility, etc., and achieves the effects of light weight, simple structure, convenient and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

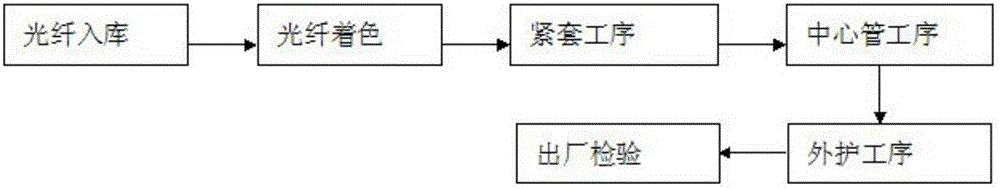

[0035] This embodiment discloses a manufacturing method of central tube FTTH reinforced drop optical cable, the process flow is as follows figure 1 As shown in , the method includes the following process steps:

[0036] Fiber warehousing: Screen the warehousing optical fibers, and select optical fibers with qualified transmission performance and tension.

[0037] Optical fiber coloring: The standard full color spectrum is used to mark the optical fiber. The marked optical fiber does not fade under high temperature and is easy to identify when splicing.

[0038] Tight sleeve process: The optical fiber is covered with a tight cladding material to make a tight sleeve optical fiber.

[0039] Center tube process: Coat the above-mentioned tight-packed optical fiber with a dry-type water-blocking material as a dry-type water-blocking layer, then extrude a layer of center-tube material outside the above-mentioned dry-type water-blocking layer, and then cover it with a dry-type loose ...

Embodiment 2

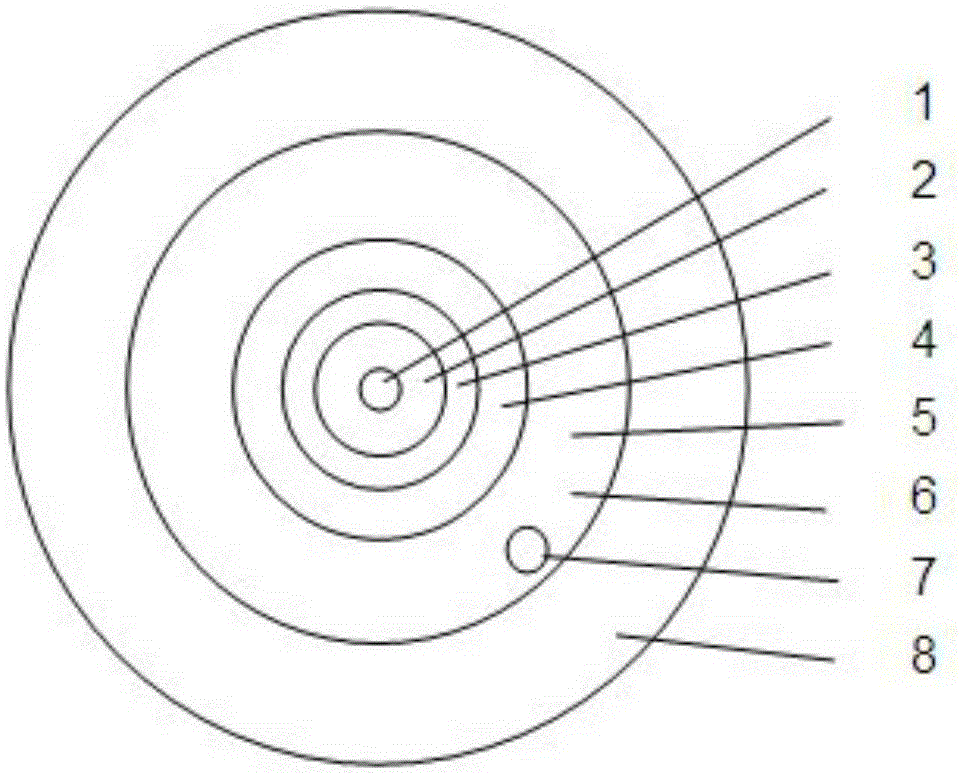

[0050] Embodiment 2 Prepare the optical cable with the manufacturing method of the central tube FTTH reinforced drop optical cable disclosed in Embodiment 1. When designing the structure of the optical cable, in combination with the preparation process in Embodiment 1, pay attention to the following four points:

[0051] 1. The structure of the optical cable adopts a central tube structure, which can ensure that the performance will not be affected during the cable forming process. At the same time, in order to meet the flexibility and lateral pressure resistance of the optical cable, the material of the central tube adopts a specific polybutylene terephthalate Glycol ester (PBT) material, the central tube structure adds a dry water-blocking compound outside the 0.9mm tight-packed optical fiber, and then extrudes a layer of polybutylene terephthalate material, and the outer diameter of the sleeve is controlled at 2.0mm .

[0052] 2. The casing of the optical cable adopts a dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com