Sodium ion battery negative electrode pre-sodium modification method, obtained negative electrode material and sodium ion battery

A sodium ion battery and negative electrode material technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low efficiency in the first week, and achieve the effects of short reaction time, strong safety, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

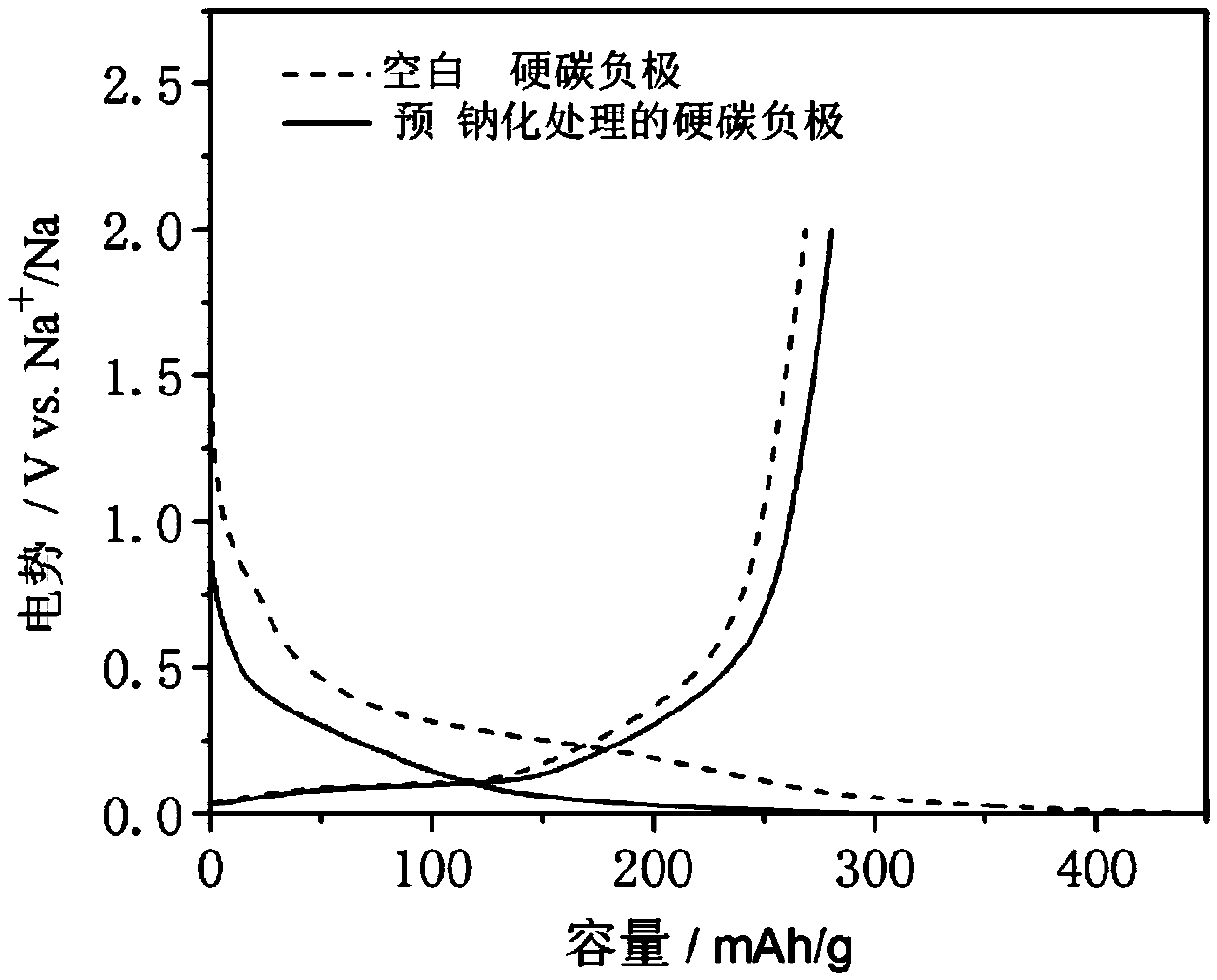

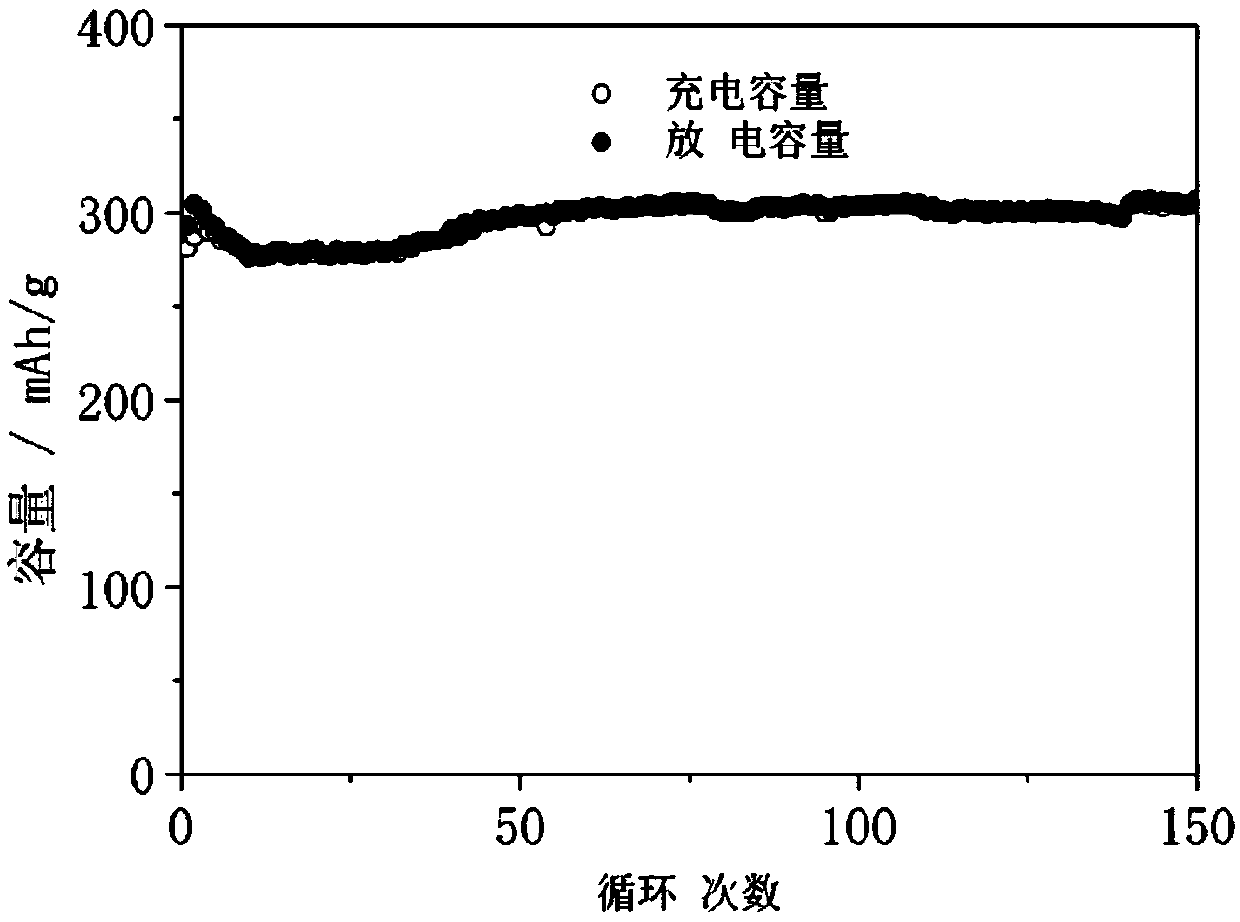

[0025] Mix equimolar biphenyl and metal sodium, dissolve in ethylene glycol dimethyl ether solvent, and prepare 0.25mol / L biphenyl sodium solution. Take 10mL of sodium biphenyl solution, add 1g of hard carbon powder, and react for 10min under the protection of an inert atmosphere. The product is suction-filtered, washed and dried to obtain a pre-sodiumized hard carbon material, and the hard carbon material is used as a negative electrode active material to prepare a negative electrode sheet. figure 1 The first-week charge-discharge curves of the negative electrode sheet with the hard carbon material as the active material were compared before and after pre-sodiumization. It can be seen from the figure that the first-week efficiency of the untreated hard carbon anode is only 60.7%, and the first-week efficiency is significantly increased to 95.8% after pre-sodium treatment; meanwhile, the first-week reversible capacity slightly increases from 269mAh / g to 293mAh / g. figure 2 It...

Embodiment 2

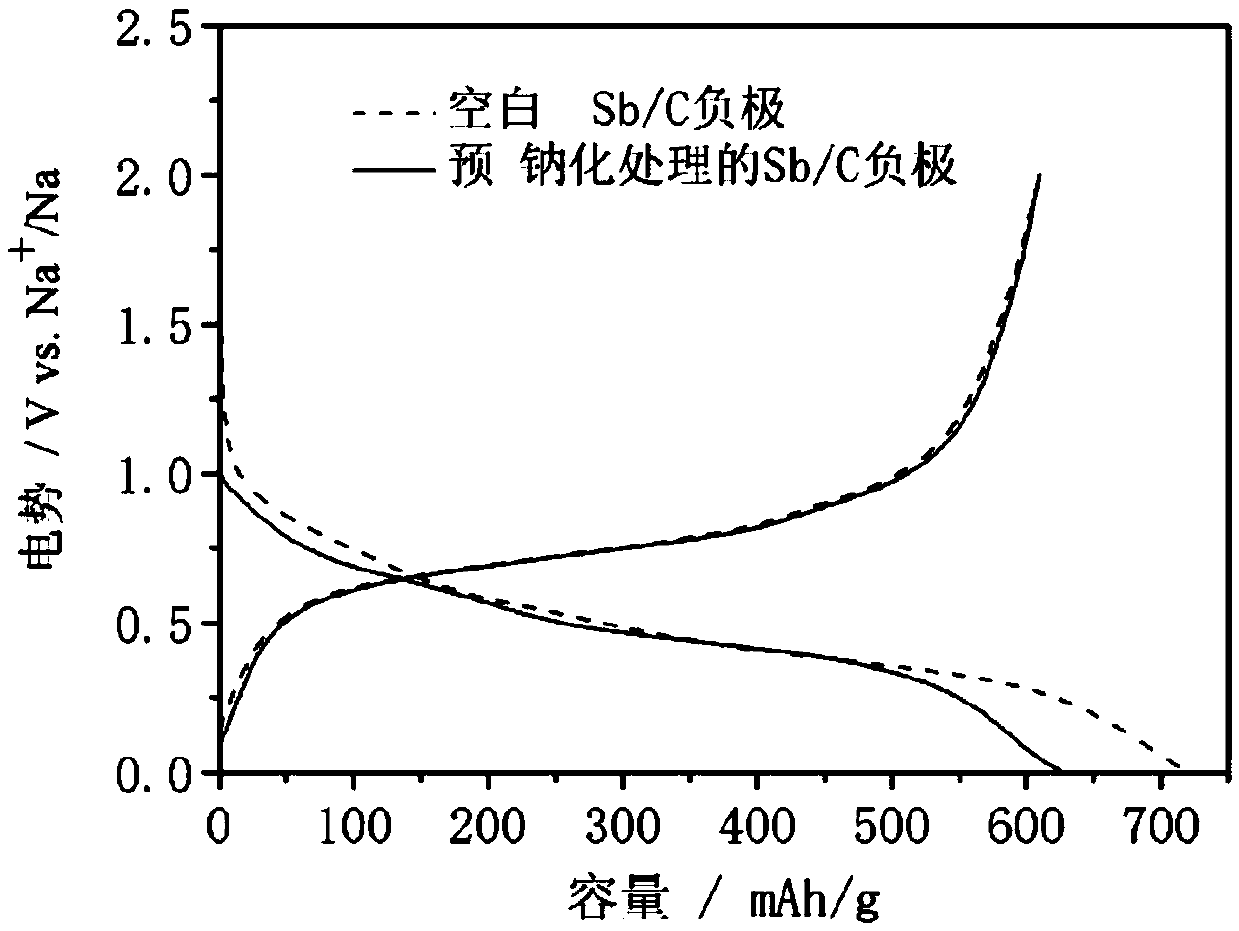

[0027] Mix equimolar naphthalene and metallic sodium, and dissolve them in a solvent of diglyme, to obtain a 0.5 mol / L sodium naphthalene solution. The Sb / C composite electrode sheet is soaked in the sodium naphthalene solution for 30 minutes to react, and after the reaction is completed, it is washed and dried to obtain a pre-sodiumized Sb / C negative electrode sheet. image 3 The charge-discharge curves of the Sb / C anode in the first week before and after pre-sodium treatment were compared. It can be seen from the figure that the first-week efficiency of the untreated Sb / C anode is only 85.23%, and the first-week efficiency increases to 97.5% after pre-sodium treatment, and the reversible capacity of the material remains almost unchanged.

Embodiment 3

[0029] Mix equimolar phenanthrene and sodium metal and dissolve in tetraethylene glycol dimethyl ether solvent to prepare 0.1mol / L sodium phenanthrene solution. Spray the freshly prepared sodium phenanthrene solution evenly on the Sn 4 P 3 / C electrode sheet surface, let it stand for 20 minutes, wash and dry after the reaction is completed, and then the pre-sodiumized Sn 4 P 3 / C electrode. Figure 4 Sn before and after presodiumization was compared 4 P 3 / C material charge and discharge curve. It can be seen from the figure that the untreated Sn 4 P 3 The first-week charge-discharge capacity of the / C material is 846.2 / 1055.2mAh / g, and the first-week efficiency is only 80.2%. After pre-sodium treatment, the charge-discharge capacity in the first week was 851.7 / 878.7mAh / g, and the coulombic efficiency increased to 96.9%. The surface pre-sodium treatment eliminated the irreversible capacity in the first week and improved the coulombic efficiency of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com