Preparation method and application of high-safety biomass silicon synthesized SiOx@C material

A biomass and product technology, applied in active material electrodes, electrochemical generators, structural parts, etc., can solve the problems of difficult large-scale industrial production, unsuitable large-scale production, harsh synthesis conditions, etc., to achieve enhanced stability, excellent Stable, simple and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

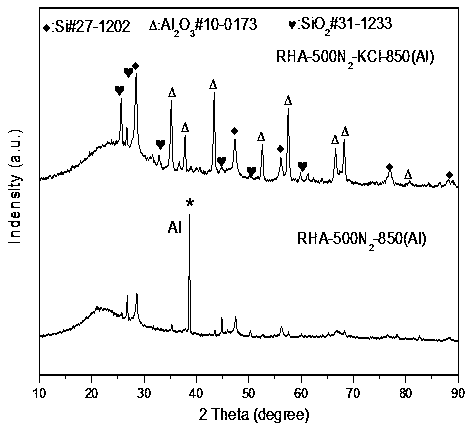

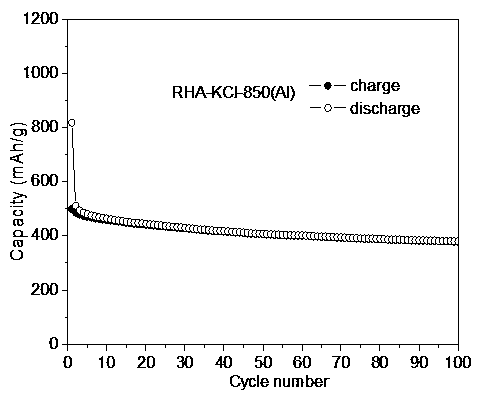

[0022] Pickle the rice husk ash, take 5g and carbonize it under nitrogen at 600°C for 1 h, mix the carbonized product with 0.2g of aluminum powder and 3 g of potassium chloride and ball mill it evenly, put it in a furnace, feed it with nitrogen, and keep it warm at 800°C 5 h, pickling and cleaning the by-product Al 2 o 3 , the product obtained is SiO x @C material; product XRD such as figure 1 As shown, the electrochemical performance of the lithium battery is as follows figure 2 shown.

Embodiment 2

[0024] Pickle the rice husk ash, take 5g and carbonize it under nitrogen for 1 h, mix the carbonized product with 0.3 g of copper powder and 3 g of potassium chloride, and ball mill it evenly, put it in a furnace, feed it with nitrogen, and keep it warm at 900°C for 4 h , pickling and cleaning the by-product CuO, and the product is SiO x @C material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com