Patents

Literature

30results about How to "Controllable oxygen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

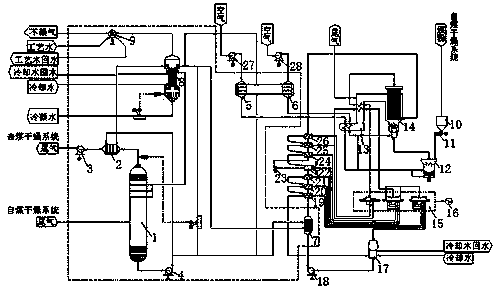

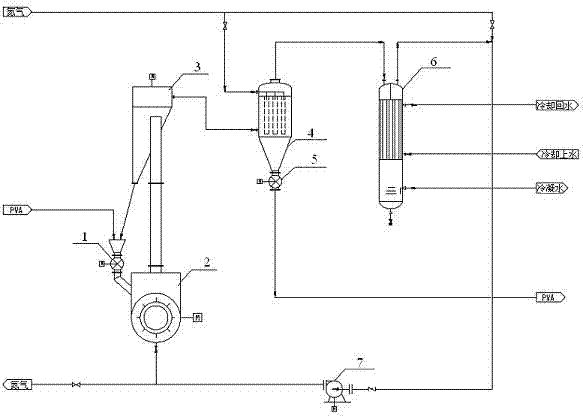

Powder coal gasification powder processing and water recovery integrated system for high-moisture coal and method of system

ActiveCN103234214AReduce water dischargeTake advantage ofDrying solid materials with heatIndirect carbon-dioxide mitigationMoistureVacuum pump

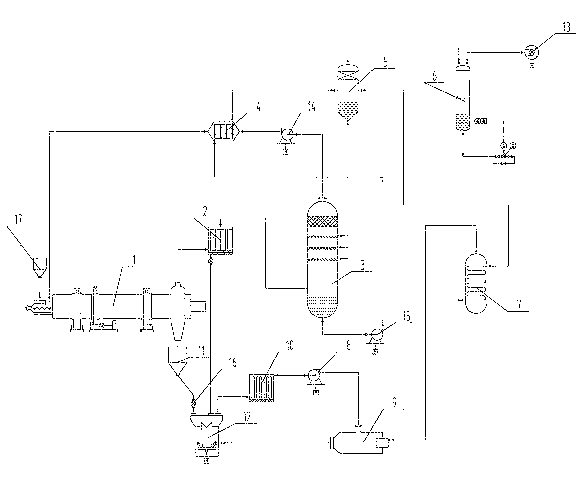

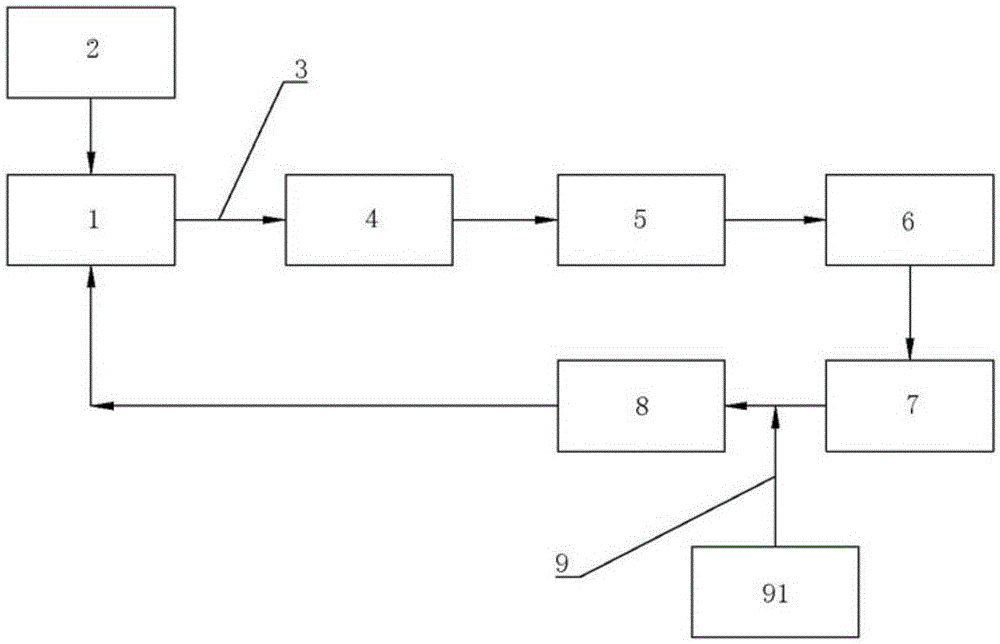

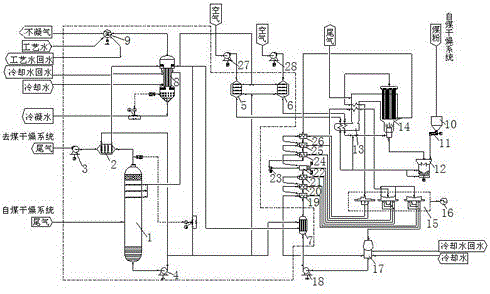

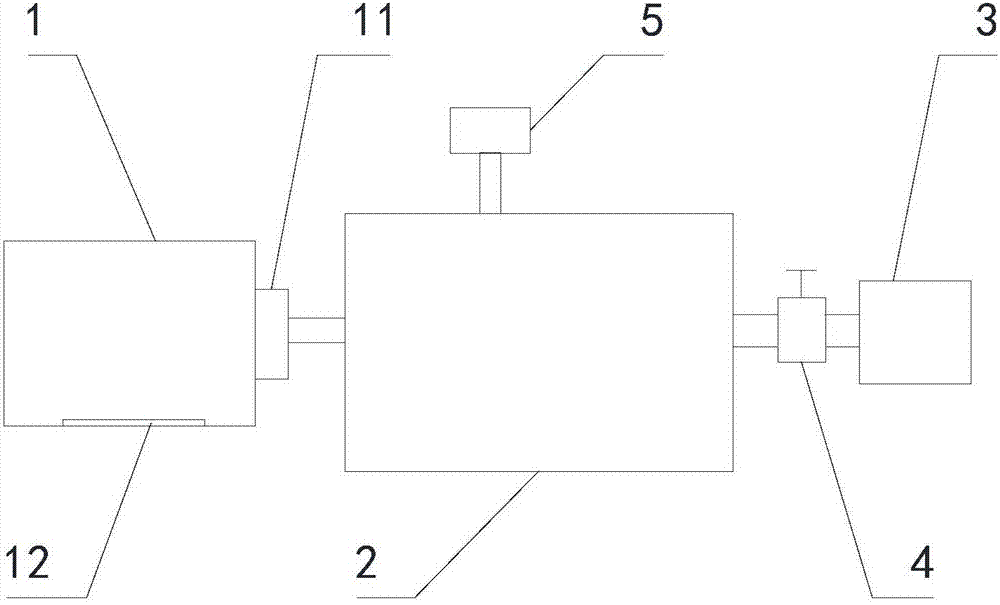

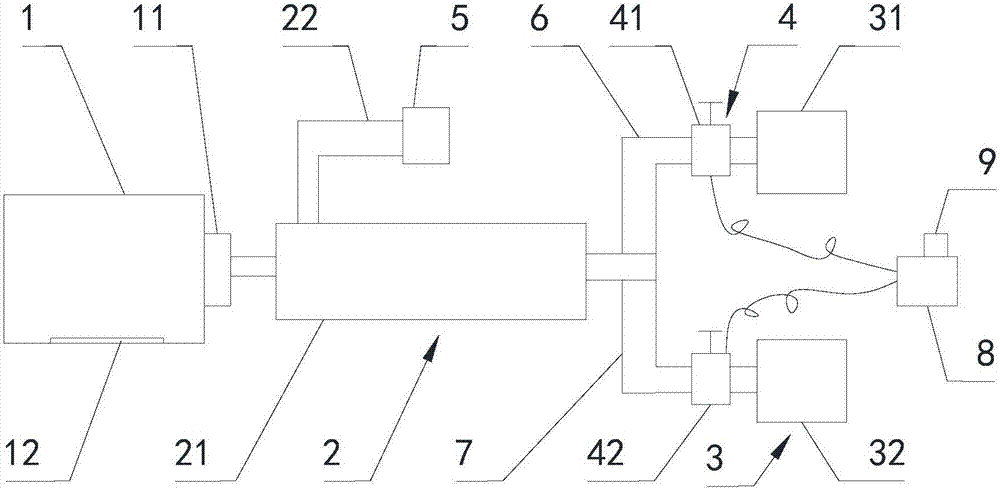

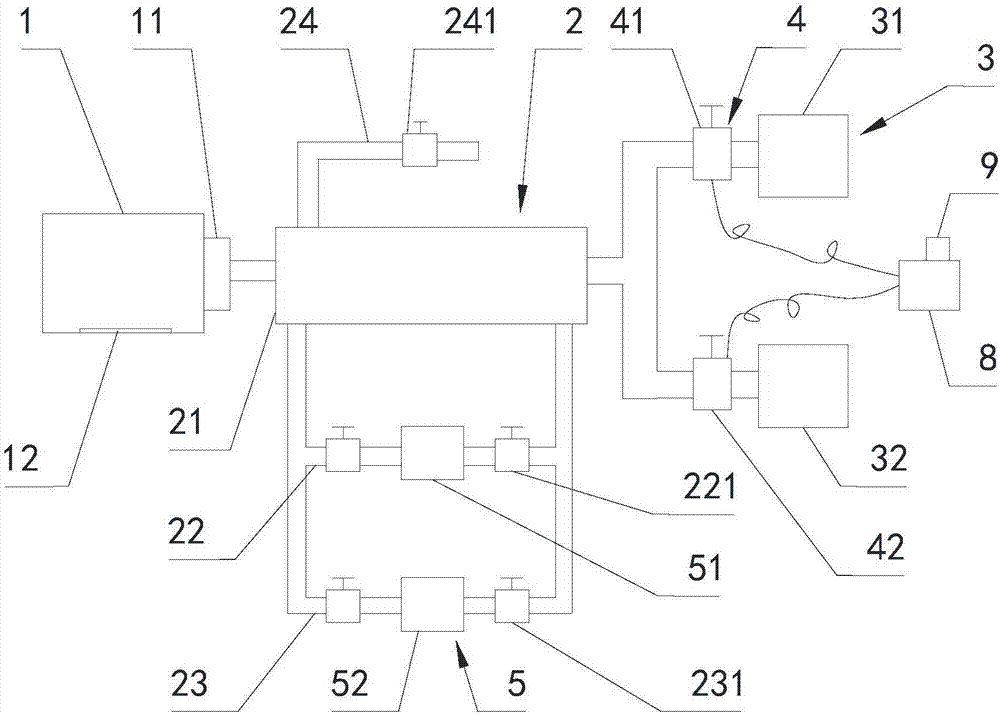

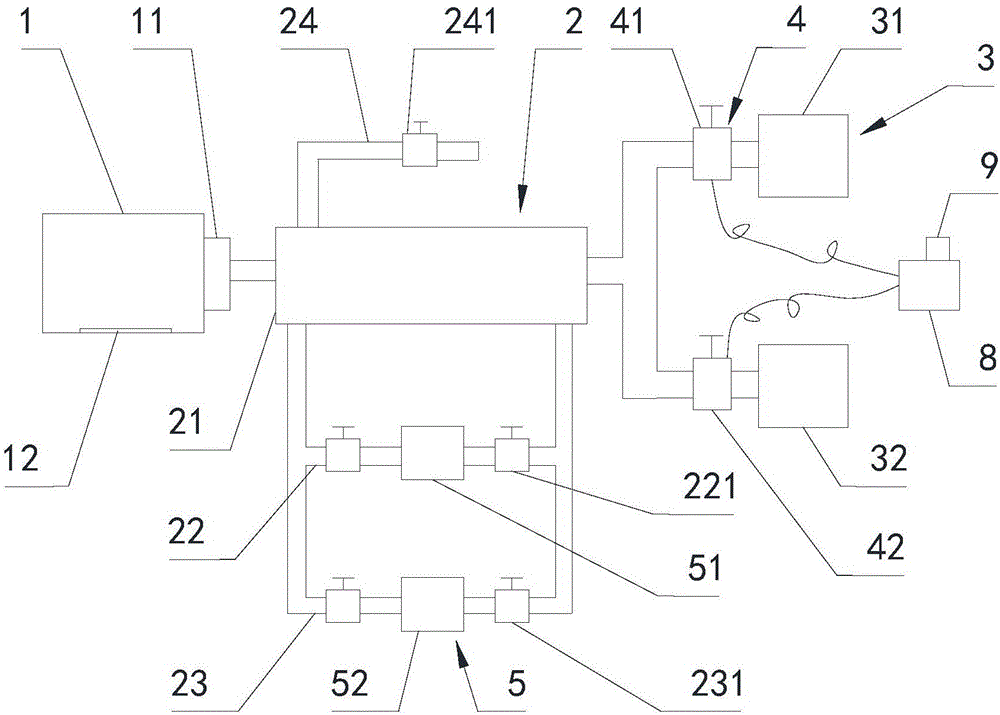

The invention relates to a powder coal gasification powder processing and water recovery integrated system for high-moisture coal. The system comprises a steam indirect heat transfer drying machine, an absorption tower, a flash tower, a vacuum pump / Venturi injection pump and a raw coal bunker. The steam indirect heat transfer drying machine is connected with the raw coal bunker, a bag-type dust collector I and a surge bunker; the surge bunker is connected with a coal mill; the coal mill is connected with a hot blast heater, and a bag-type dust collector II and a delivery pipe II are arranged at the top of the coal mill respectively; the top of the absorption tower is connected with a carrier gas initial heater, a circulating pump is arranged at the bottom, and the side of the absorption tower is connected with the flash tower; the circulating pump is connected with an air heater and connected with the carrier gas initial heater; the air heater is connected with the flash tower and the hot blast heater respectively; the flash tower is connected with a condenser which is connected with the vacuum pump / Venturi injection pump; and the flash tower is connected with the carrier gas initial heater. The invention further discloses an application method of the system. According to the system and the method, the investment is small, and energy consumption can be reduced effectively.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

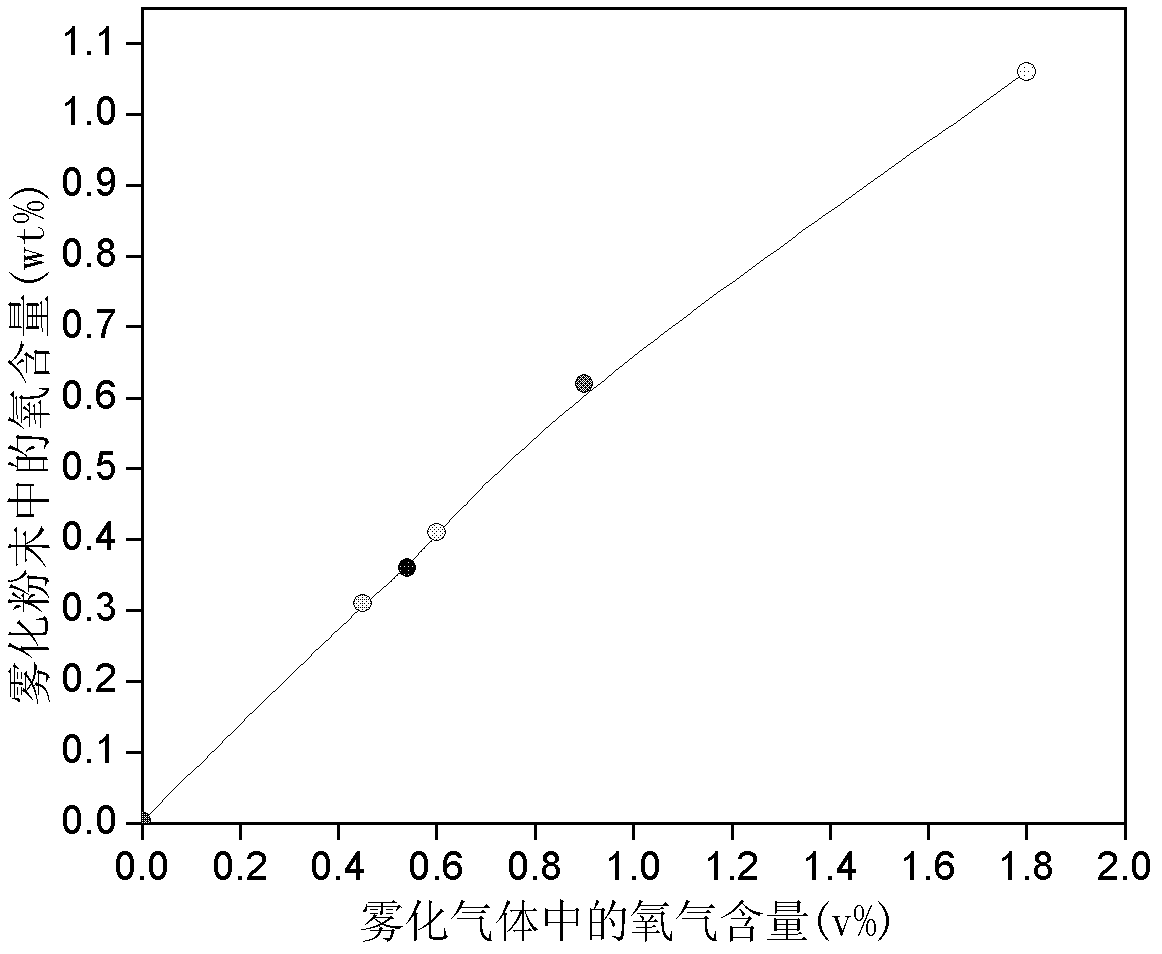

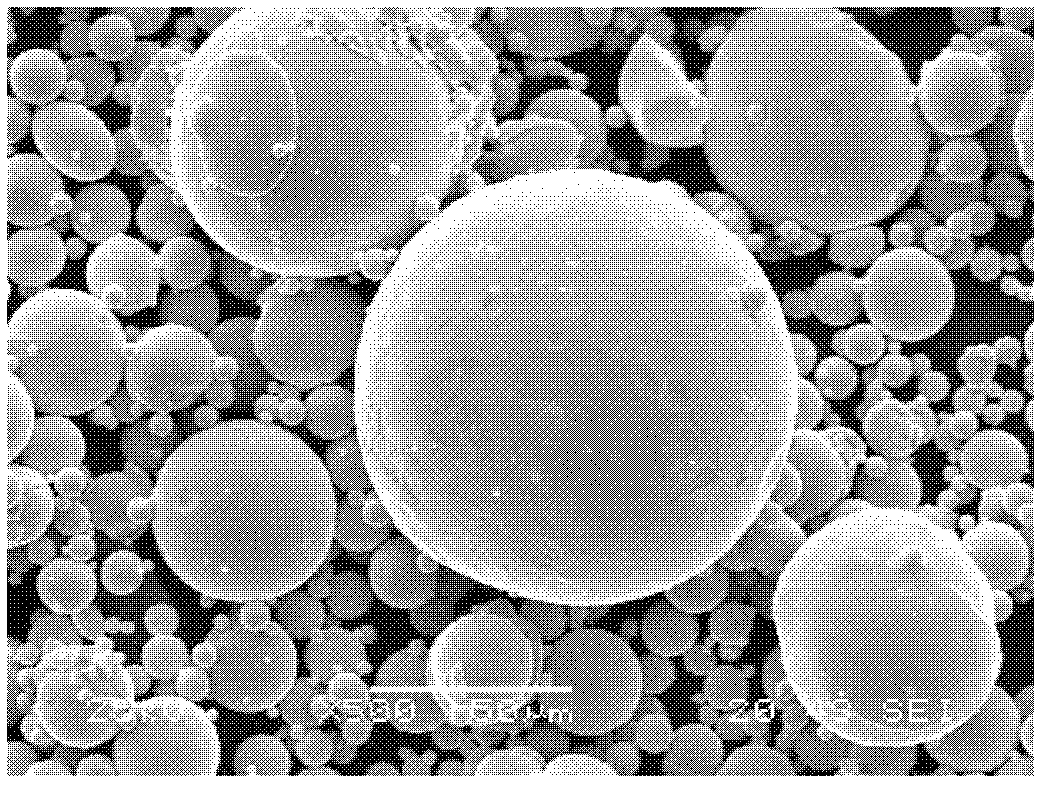

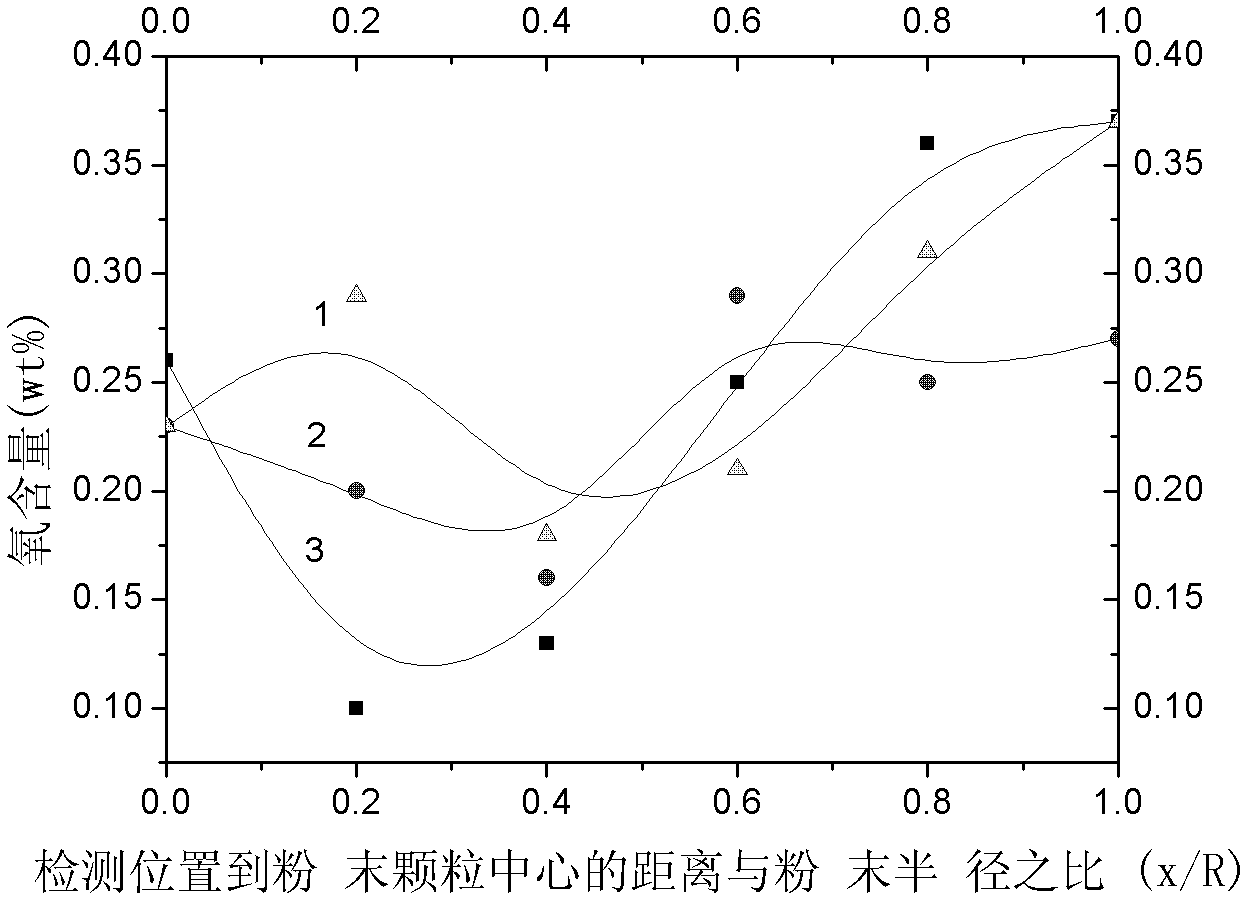

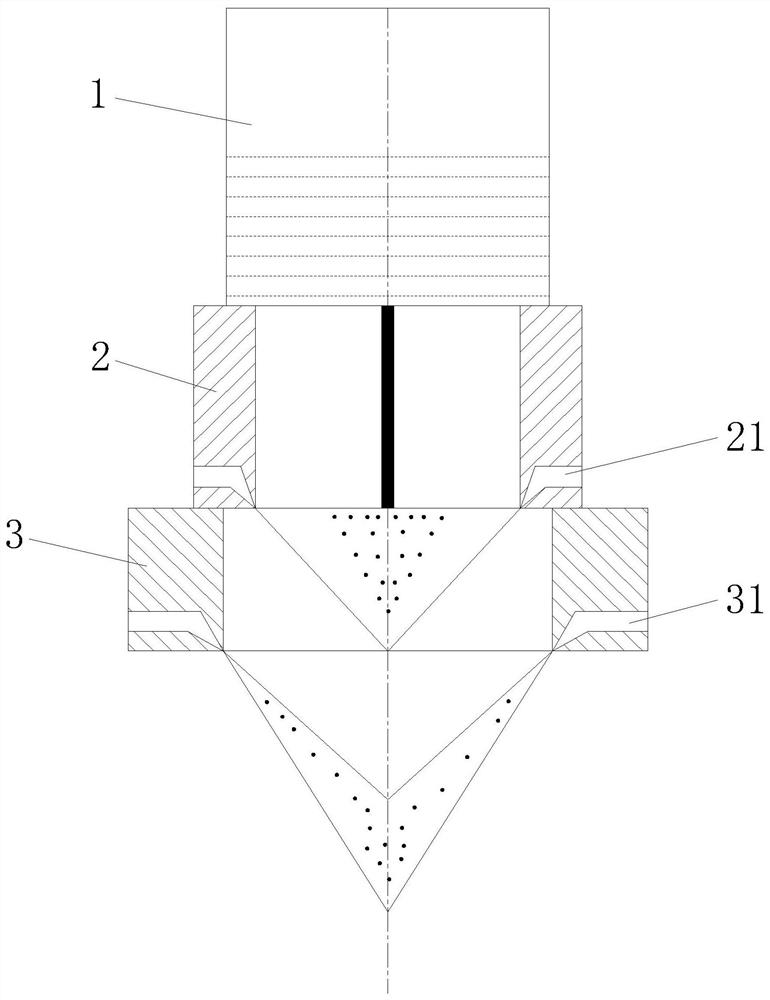

Gas atomization method for preparing oxygen supersaturated iron-based alloy powder

The invention relates to a gas atomization method for preparing oxygen supersaturated iron-based alloy powder. The iron-based alloy powder is prepared by the gas atomization method, an alloy melt is subjected to high-speed gas atomization and quick cooling by comprehensively controlling the oxygen content and atomization pressure of an atomization medium and the superheat degree of the melt, oxygen is introduced in the atomization process, the oxygen content of atomized powder is controlled by controlling the oxygen content of atomization gas, high-concentration solid solution oxygen and high-concentration vacancies are obtained according to the quick solidification characteristic of gas atomization, the oxygen is prevented from reacting with alloy elements so as not to form stable oxide, and a high-purity high-quality powder raw material is provided for preparing a nano cluster strengthened alloy. The oxygen content of the iron-based alloy powder prepared by the gas atomization method is controllable in the range of less than or equal to 1.00 percent, the oxide is not generated, and the method is particularly suitable for preparing the iron-based alloy powder containing high-activity alloy elements such as rare earth, Ti, Cr and the like, and is simple, high in production efficiency, low in cost and suitable for large-scale production.

Owner:CENT SOUTH UNIV

Method for preparing titanium and titanium alloy powder for 3D printing on basis of fluidized bed jet milling technology

ActiveCN109877329AIncrease productivitySave energyAdditive manufacturing apparatusTransportation and packagingThermal sprayingDehydrogenation

The invention discloses a method for preparing titanium and titanium alloy powder for 3D printing on the basis of a fluidized bed jet milling technology, and belongs to the field of powder preparationand modification. According to the method, hydrogenated dehydrogenation titanium powder and titanium alloy powder are adopted as main raw material powder, jet milling and shaping are carried out under the protective atmosphere of nitrogen or argon, and finally the high-performance titanium and titanium alloy powder meeting the 3D printing technology is obtained. Compared with the prior art, the method has the advantages of being high in production efficiency, low in production cost and the like. The prepared titanium and titanium alloy powder also has the advantages of being narrow in particle size distribution, close to the spherical shape, controllable in oxygen content, good in liquidity, high in purity and the like, therefore, the industrial production technical requirements of 3D printing, injection molding, thermal spraying and the like can be met.

Owner:UNIV OF SCI & TECH BEIJING

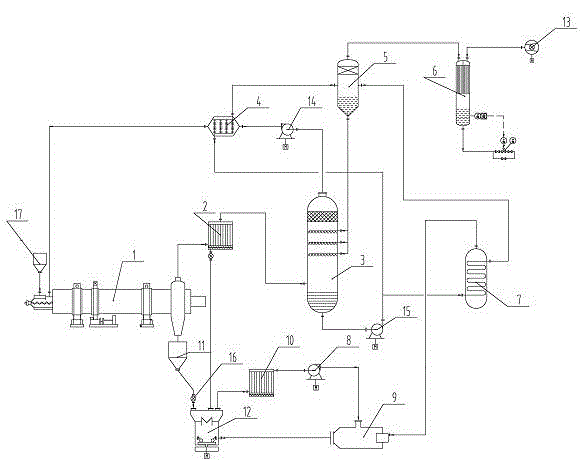

Method of utilizing coal drying exhaust steam to reduce coal consumption of coal-fired power generator set and recovering water

ActiveCN103968659AReduce coal consumption for power supplyIncrease temperatureDrying solid materialsProcess engineeringThermal water

The invention relates to a method of utilizing coal drying exhaust steam to reduce coal consumption of a coal-fired power generator set and recovering water. The method is to add a heat and water recovery system between a coal drying system and the coal-fired power generator set, wherein the heat and water recovery system can convert heat and water vapor carried by the dry tail gas to heat and water carried by hot water, and then the hot water carrying a lot of heat is used for preheating carrier gas entering the coal drying system, air entering a coal-fired boiler system and condensed water after condensing steam by a steam turbine in order to realize efficient transfer of the heat carried by the dry tail gas to the coal-fired power generator set, reduce the coal consumption for the coal-fired power generator set and recover water. The method is characterized by completely recovering and utilizing heat and water vapor carried by the dry tail gas, so as to obviously reduce the coal consumption of a power plant, and conform to the national industry policy of energy conservation and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Activated coal modified material for removing thiophen compounds in gasoline and method for preparing and using the same

InactiveCN101462041AEasy to makeControllable oxygen contentOther chemical processesHydrocarbon oils refiningActivated carbonHydrofluoric acid

The invention relates to a method for modifying active carbon for removing thiophene compounds in gasoline. The technical proposal comprises that: ozone is used as an oxidizing medium to oxidation and modify the active carbon so as to obtain an active carbon adsorbing material with higher sulfur capacity. The method comprises: using a mixed acid of a hydrochloric acid and a hydrofluoric acid to remove ash from the active carbon, using deionized water to wash the active carbon to be neutral, soaking the active carbon in a 1 to 4mol / L sodium hydroxide solution, placing the active carbon in a reaction container after filtering, introducing 5 to 15mg / L ozone-air gas mixture, using the deionized water to wash the active carbon to be neutral, and performing filtering and drying to obtain the active carbon adsorbing material with higher sulfur capacity. Compared with non-modified active carbon, the active carbon modified by the method obviously improves the sulfur capacity of the thiophene compounds in the gasoline, and can be applied to absorption and desulfurization processes of the gasoline; at normal temperature and normal pressure, the active carbon can absorb and remove the thiophene compounds in the gasoline, and the removal rate is more than 80 percent; and in the recycling process, the efficiency of the active carbon is almost kept unchanged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

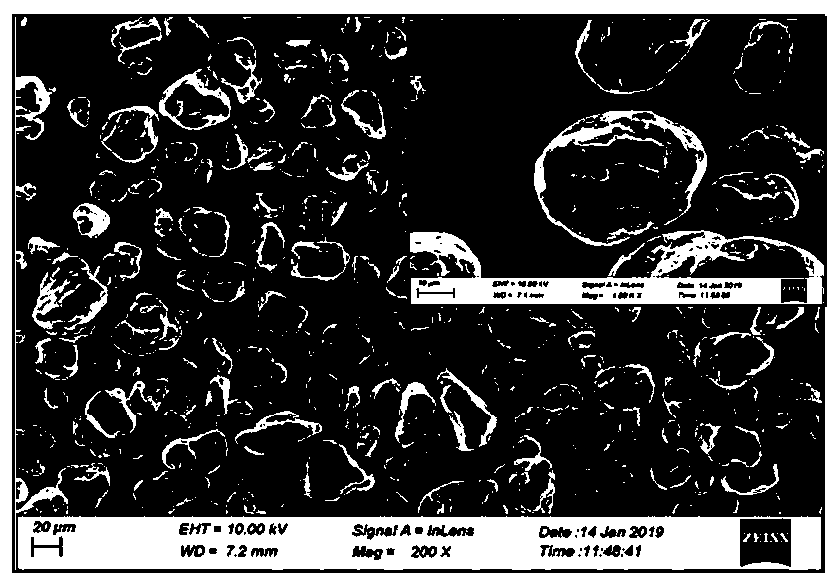

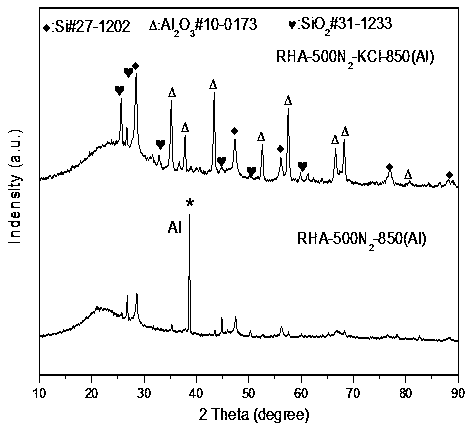

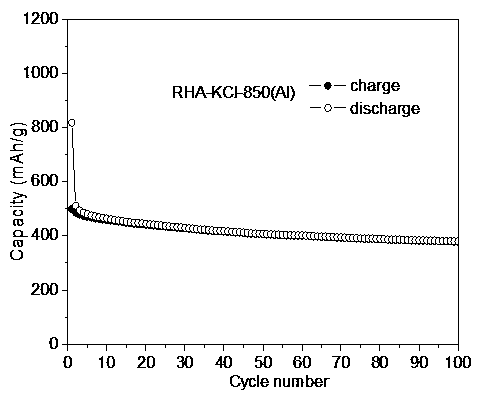

Preparation method and application of high-safety biomass silicon synthesized SiOx@C material

ActiveCN110867567AImprove stabilityImproved magnification performanceNegative electrodesSecondary cellsCarbon coatingCarbonization

The invention provides a preparation method of a high-safety biomass silicon synthesized SiOx@C material. The method comprises the following steps: pickling rice hull ash, carbonizing a proper amountof the rice hull ash in an inert atmosphere, uniformly mixing and ball-milling the carbonized product, metal powder and molten salt, putting the mixture into a furnace, introducing inert gas, carryingout a high-temperature reaction, and pickling to clean byproducts to obtain the product of the SiOx@C material. The method is simple and feasible in process, rich and cheap in raw materials and higher in safety compared with magnesiothermic reduction, and the obtained SiOx@C particles have porous structures, are uniform in carbon coating and good in rate capability and can be applied to the fieldof lithium battery negative electrode materials.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

Continuous casting and rolling production process of oxygen-free copper rod

ActiveCN107214194AImprove qualityControllable oxygen contentMetal rolling arrangementsOxidation resistantNozzle

The invention discloses a continuous casting and rolling production process of an oxygen-free copper rod. The continuous casting and rolling production process comprises the following steps of putting electrolytic copper raw materials in a sealed mixing melting furnace for smelting, introducing reduction gas, then discharging from a copper outlet of the sealed mixing melting furnace, flowing into a molten copper casting ladle through a molten copper diversion trench, opening a casting gate of the molten copper casting ladle, continuously and uniformly pouring molten copper to a continuous casting crystallizer through a stainless steel pouring nozzle of the molten copper casting ladle so as to form a continuous casting copper ingot, quickly and uniformly applying oxidation resistant lubricating oil to the surface of the continuous casting copper ingot, sending to a rolling mill so as to be rolled into the oxygen-free copper rod, cooling the oxygen-free copper rod until the temperature of the oxygen-free copper rod is reduced below 80 DEG C, then wiping to remove the oxidation resistant oil from the surface of the oxygen-free copper rod, and then wiping the surface of the oxygen-free copper rod with a small amount of industrial alcohol so as to package and store. By adopting the continuous casting and rolling production process, the quality of the oxygen-free copper rod prepared by adopting the continuous casting and rolling process can be increased.

Owner:NANTONG MINGGUANG ELECTRIC WIRE

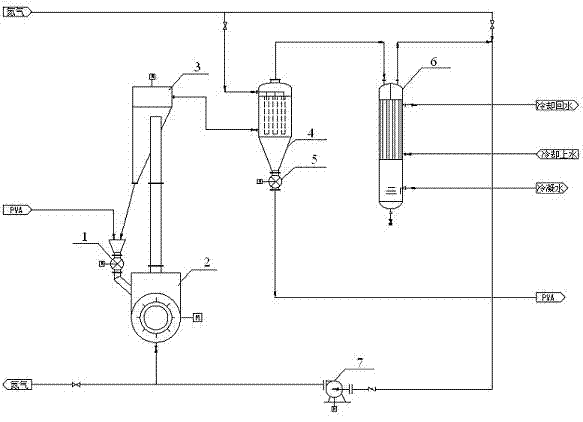

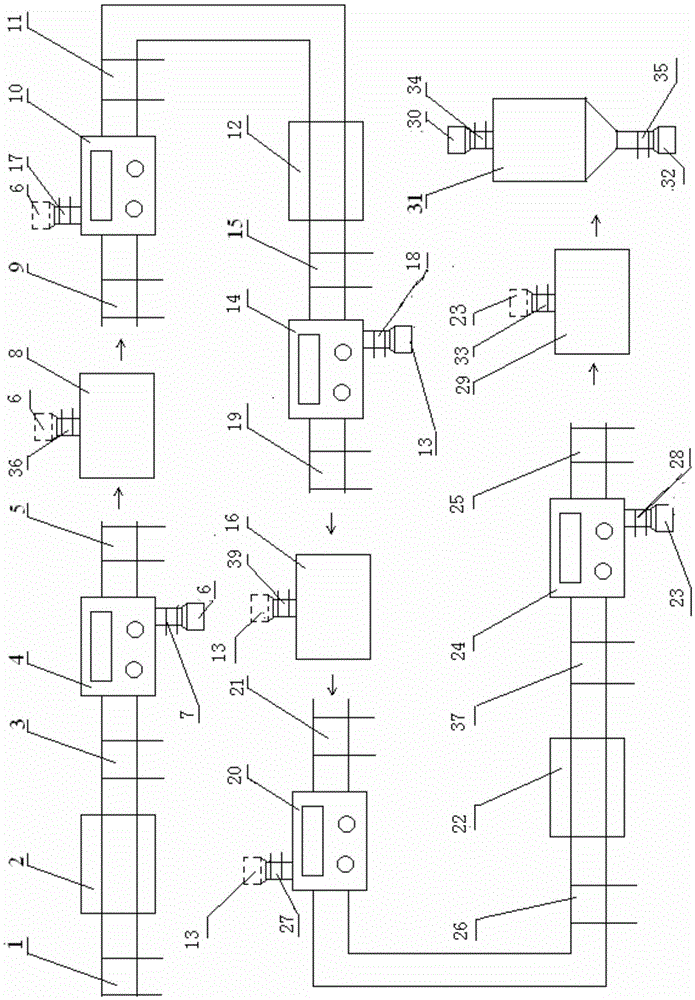

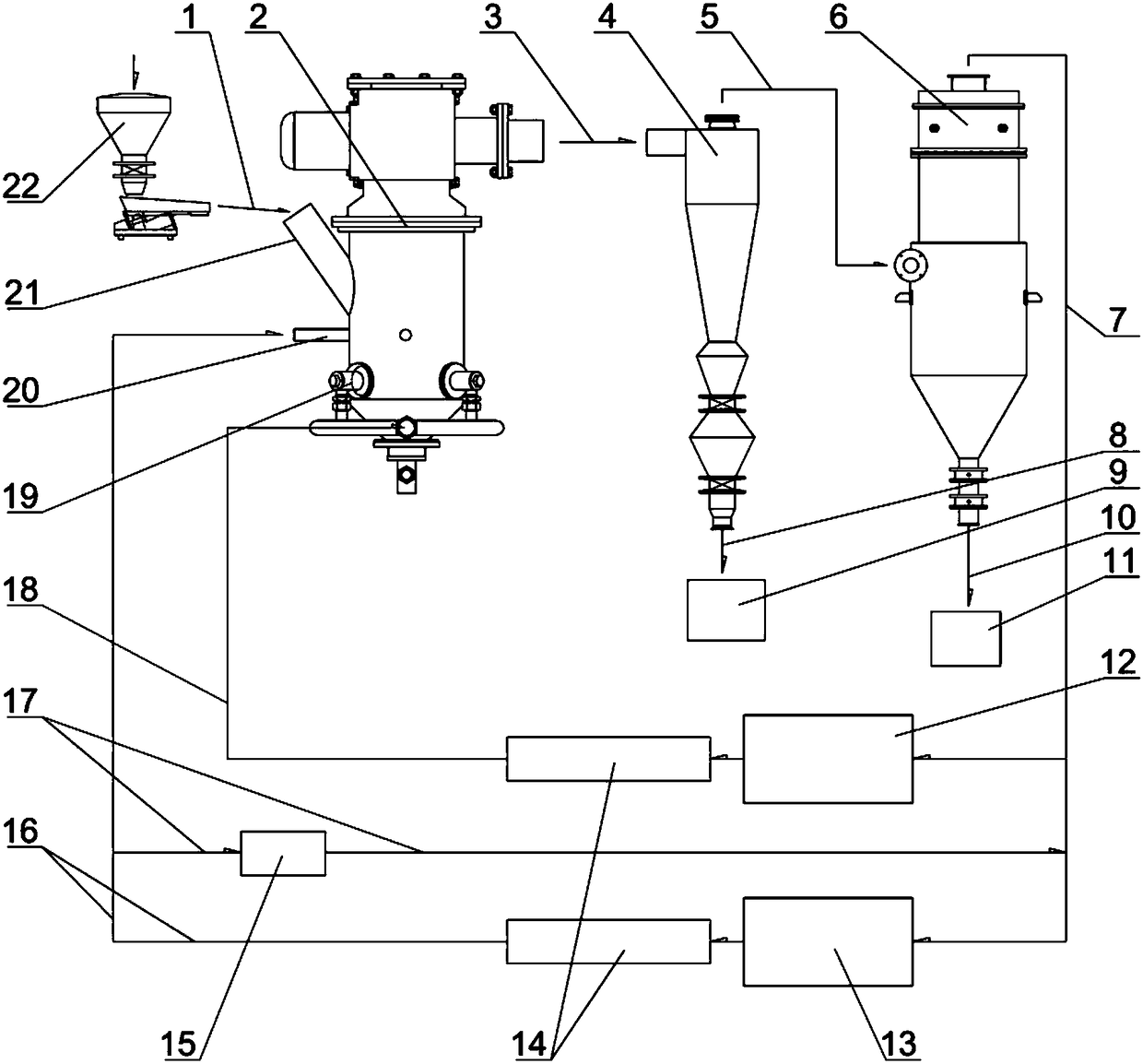

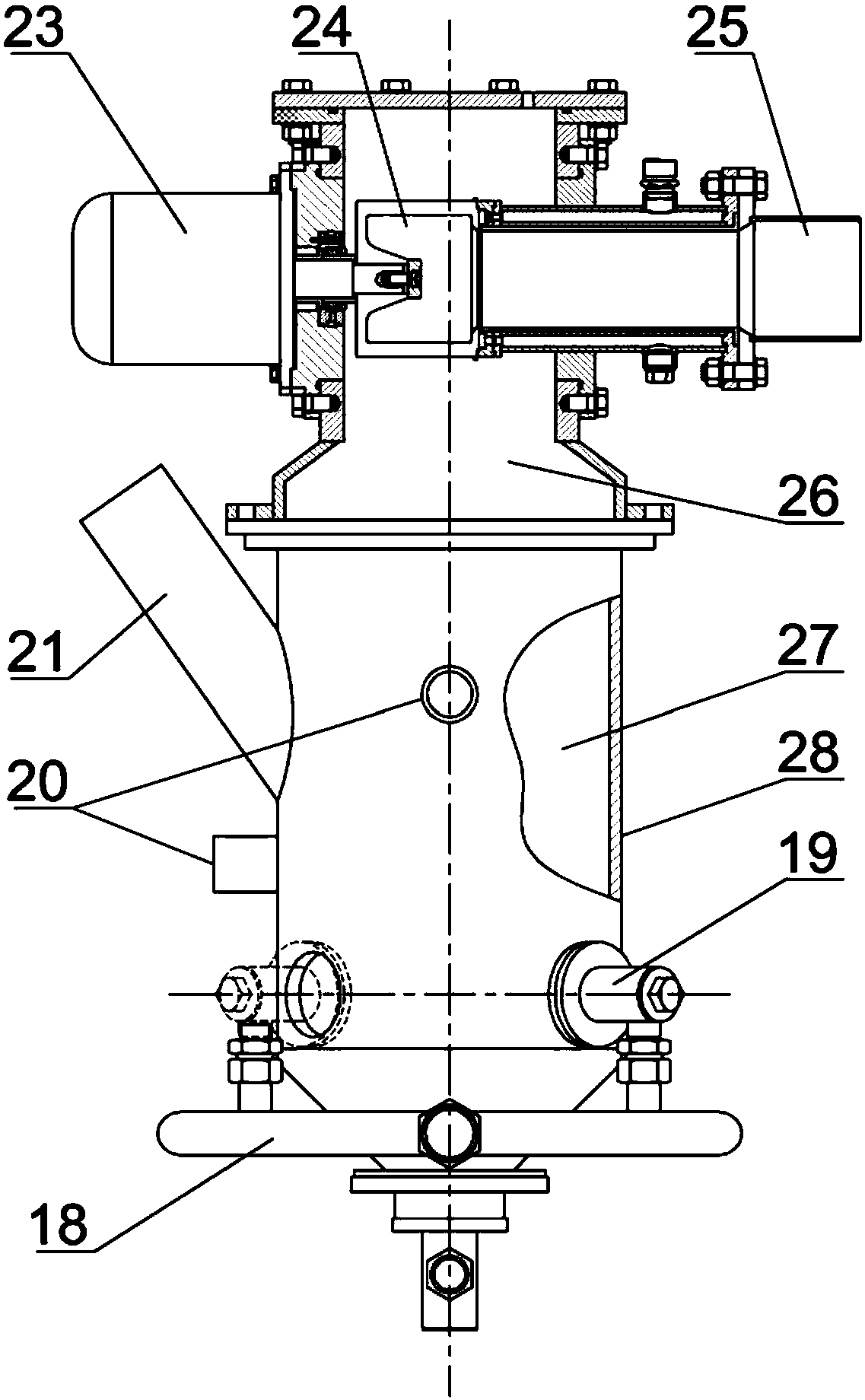

Nitrogen gas sealed circulating PVA powder processing method

ActiveCN104841544ABroken safe and reliableControllable oxygen contentGrain treatmentsNitrogen gasCrusher

The invention relates to a nitrogen gas sealed circulating PVA powder processing method. The method comprises the following steps: (1) after a PVA polymer or resin passes through a rotary gas locking device I, the PVA polymer or resin is continuously and uniformly added into a crusher to obtain PVA particles; (2) nitrogen gas is conveyed into the crusher, the PVA particles are conveyed into a grading device to be graded to obtain large-particle PVA and nitrogen gas containing qualified PVA particles, and the large-particle PVA falls into the crusher to be crushed again; (3) the nitrogen gas containing the qualified PVA particles enters a cloth bag dust remover to be subjected to gas-solid separation to obtain fine powder and separated nitrogen gas, and the fine powder passes through a rotary gas locking device II to enter a stock bin; (4) the separated nitrogen gas enters a condenser to be subjected to indirect cooling with a cooling medium to obtain condensed nitrogen gas and condensate water; and (5) the condensed nitrogen gas is boosted by a circulating draught fan and then enters the crusher to be circularly utilized in a sealed manner. The nitrogen gas sealed circulating PVA powder processing method has the characteristics of safety and low energy consumption.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

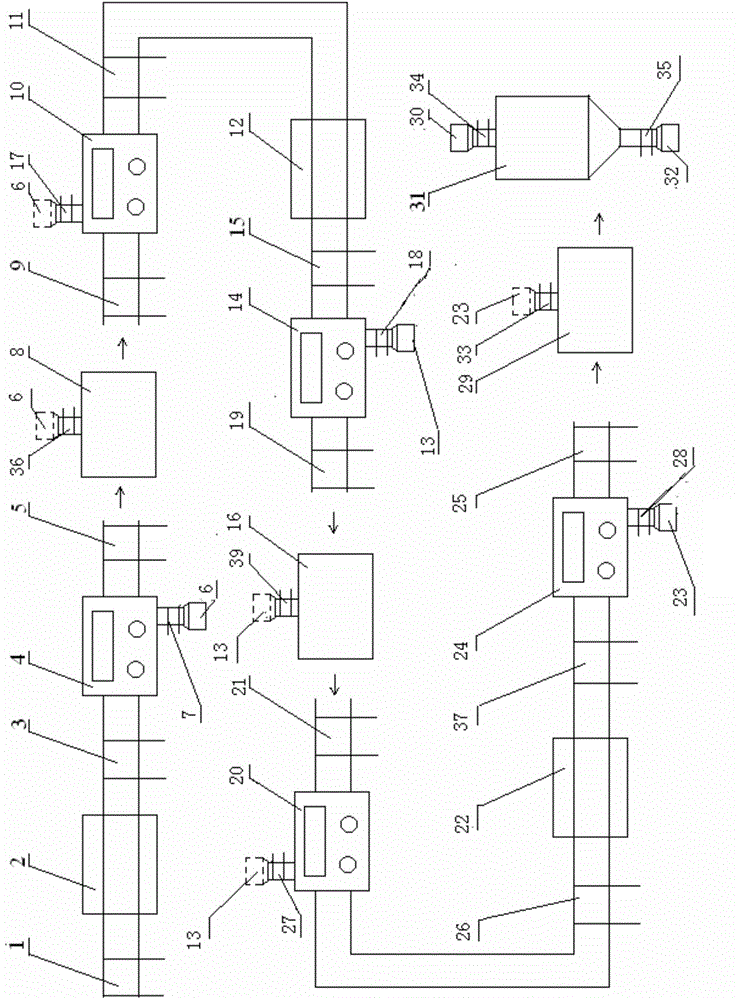

Production line for low-oxygen-content hard alloy mixture and production technology thereof

The invention relates to a production line for low-oxygen-content hard alloy mixture. The production line is a sealed system formed by a reduction part used for preparing blue tungsten powder, a reduction part used for preparing tungsten powder, a carbonization part and a pelletizing part. According to the production line disclosed by the invention, nanometer tungsten trioxide is still in the sealed production line from the rotary reduction furnace inlet of a starting end to the spraying drying tower of a tail end; the sealed production line is filled with nitrogen or hydrogen, so that nanometer powder is prevented from contacting with external air all the time so as to reduce the size of nanometer WC (wolfram carbide) particles and prevent nanometer WC from being oxidized and auto-ignited; the oxygen content of the hard alloy mixture is lowered; the stability and the controllability of the ultra-fine grain hard alloy quality are improved; the combination property of the alloy is improved.

Owner:UNIV OF SCI & TECH BEIJING

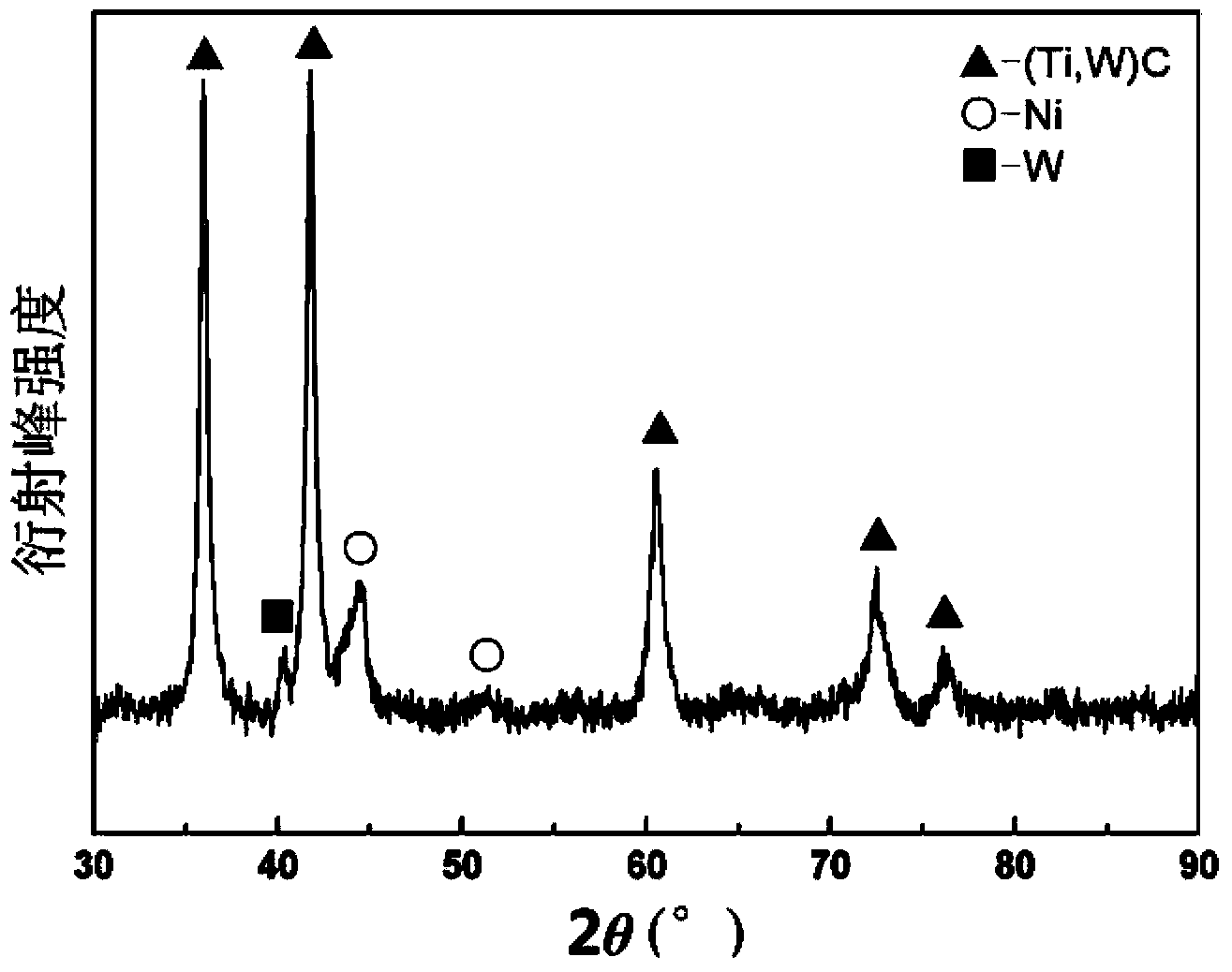

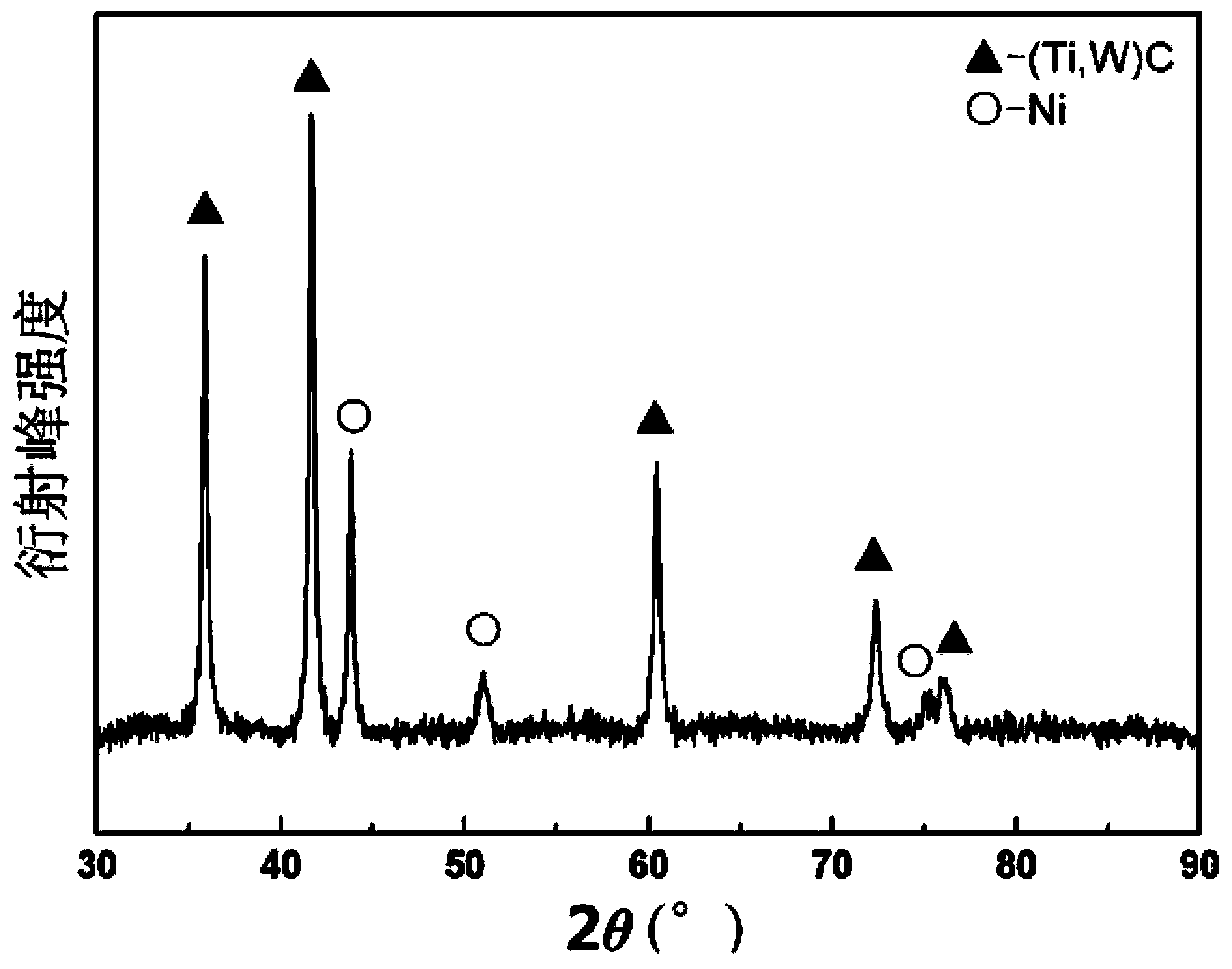

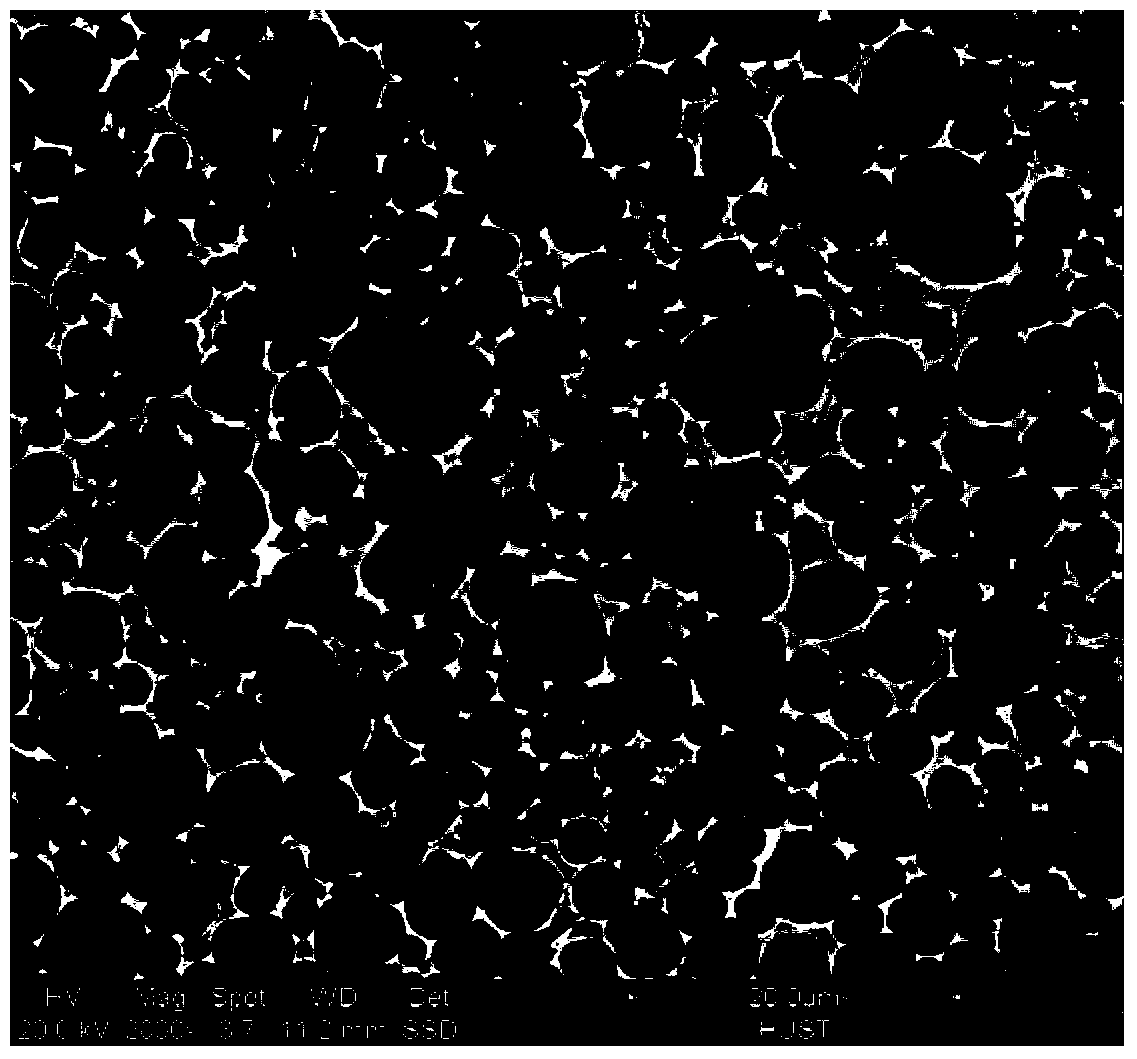

Titanium carbide-based solid solution metal ceramic and preparation method thereof

ActiveCN103361533BImprove the bonding strength of the interfaceSmall granularityWear resistantHigh energy

The invention discloses titanium carbide-based solid solution metal ceramic and a preparation method thereof. The titanium carbide-based solid solution metal ceramic is composed of a hard phase (Ti, W) C solid solution and an adhesive phase Ni, wherein the composite material powder is prepared by mold pressing forming, degreasing and vacuum sintering; the composite material is synthesized by utilizing Ti powder, W powder, Ni powder and graphite powder as raw materials and performing a high-energy ball milling induced self-propagating reaction under argon protection, and the raw materials comprise the following ingredient by mass percent: 40.60-58.02% of Ti powder, 11.02-29.18% of W powder, 15.00-20.00% of Ni powder and 11.94-15.27% of graphite powder. The preparation of solid solution powder is simple in process, short in cycle, low in energy consumption and easy to control the oxygen content, the hardness of the prepared titanium carbide-based solid solution metal ceramic is 89.0-91.8HRA, the bending strength is not smaller than 1680MPa, and the fracture toughness KIC is not smaller than 12.5MPa.m1 / 2, so that the titanium carbide-based solid solution metal ceramic is suitable for serving as high-speed and high-efficiency cutting tools, hot extrusion molds and heat-resistant, corrosion-resistant and wear-resistant parts and components.

Owner:HUAZHONG UNIV OF SCI & TECH

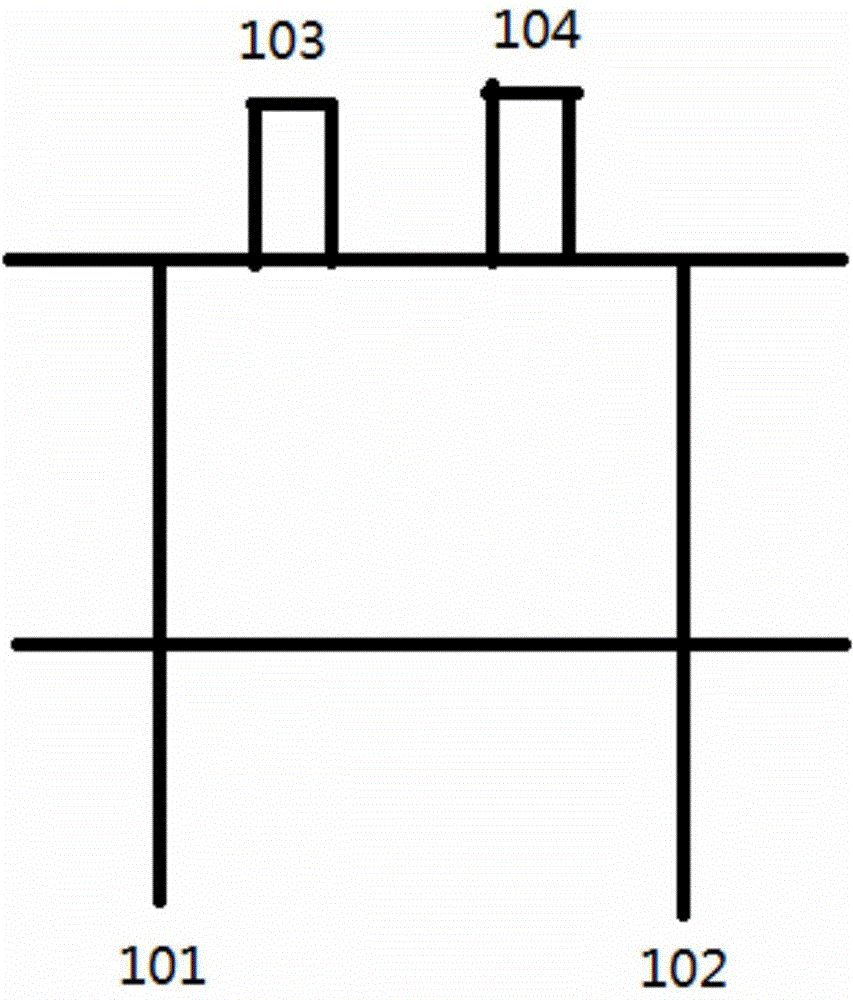

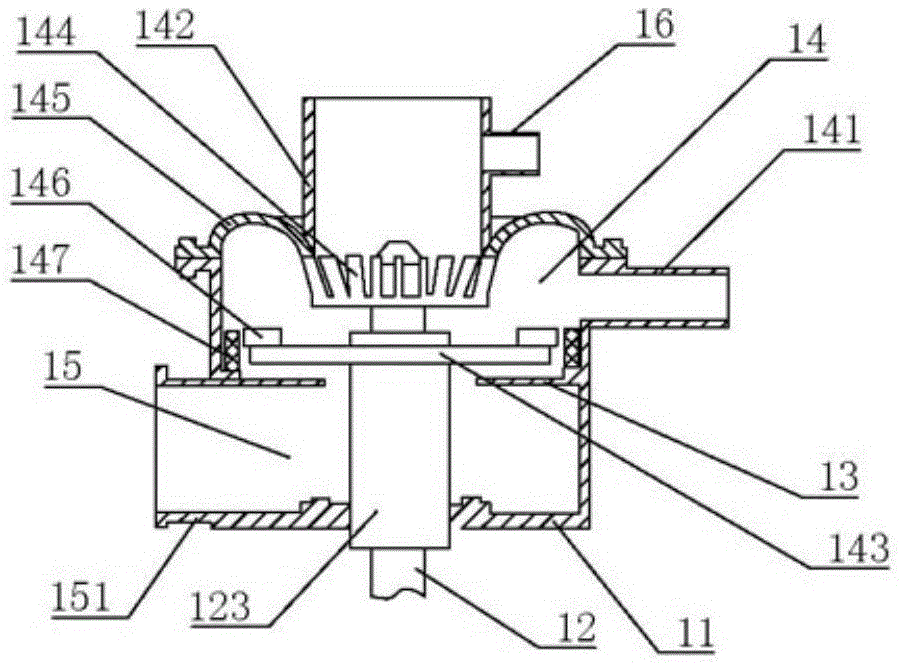

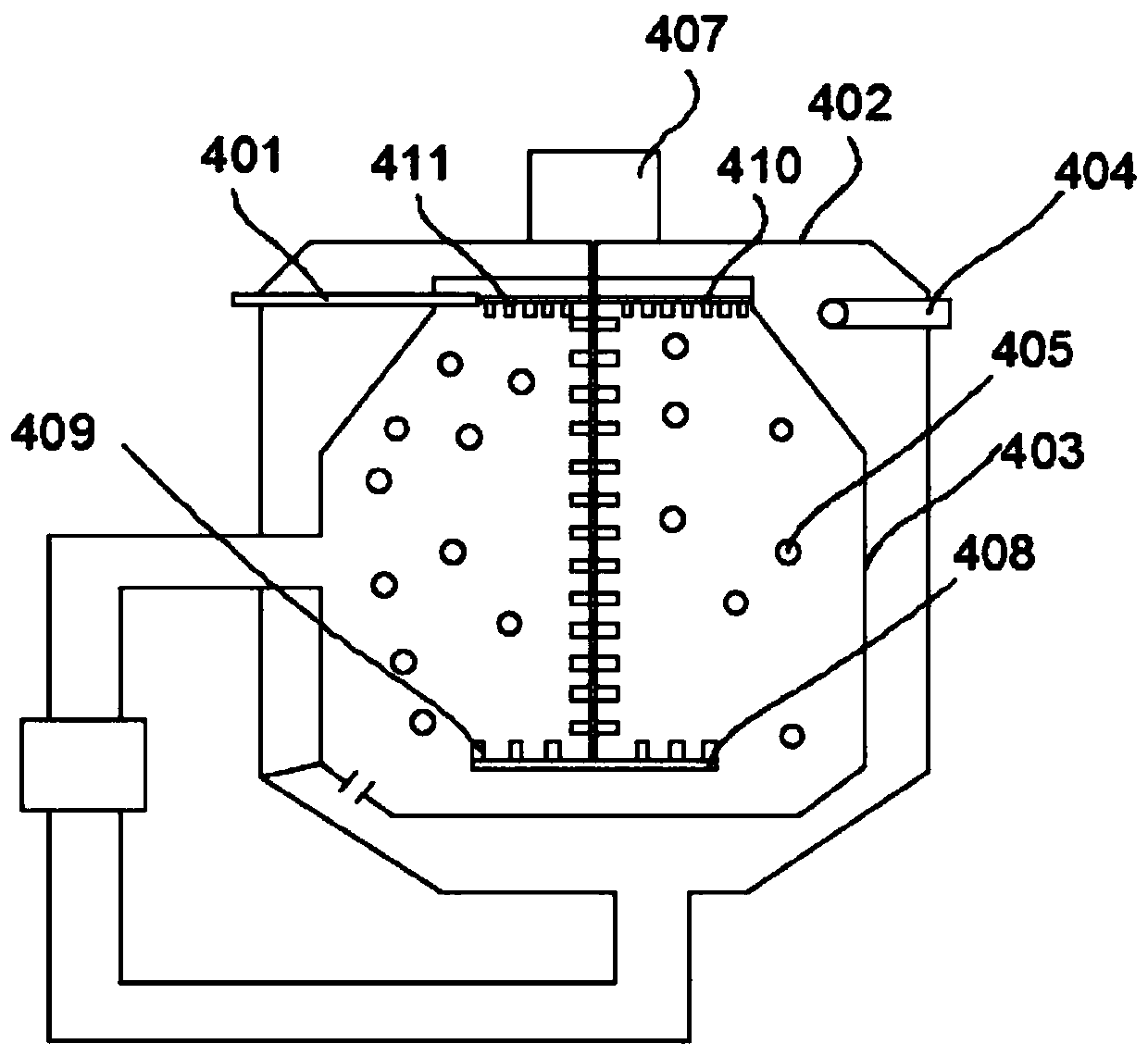

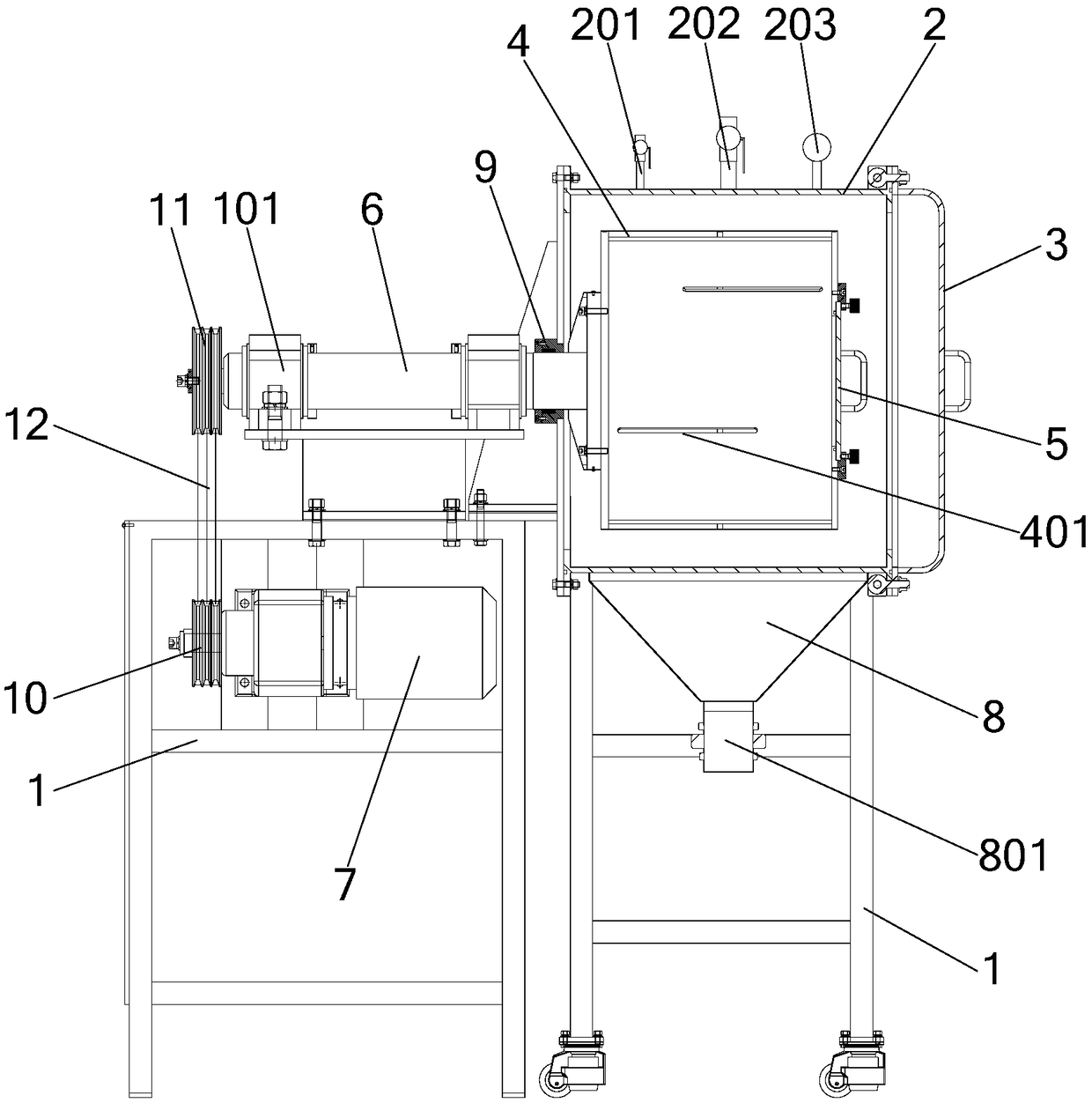

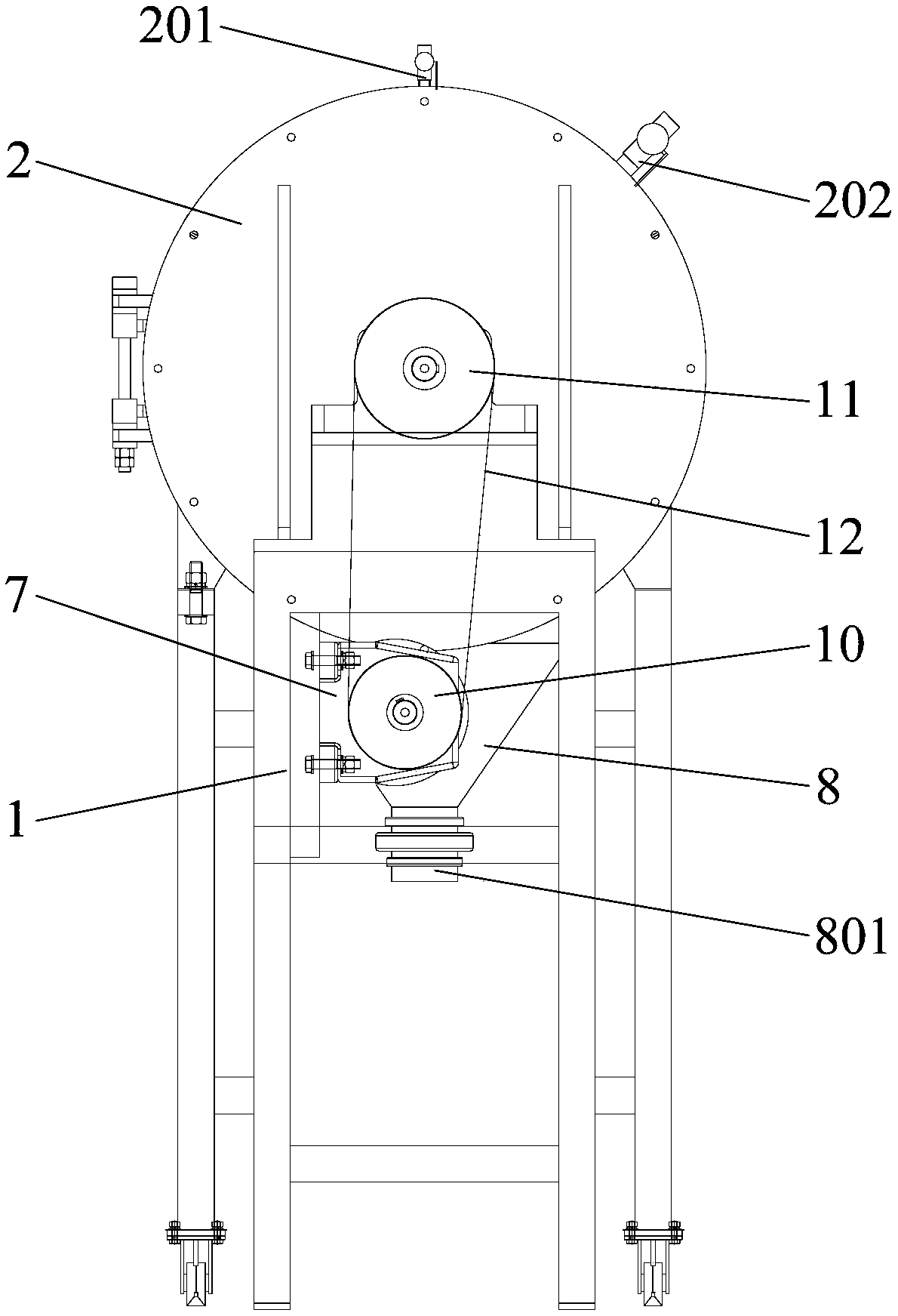

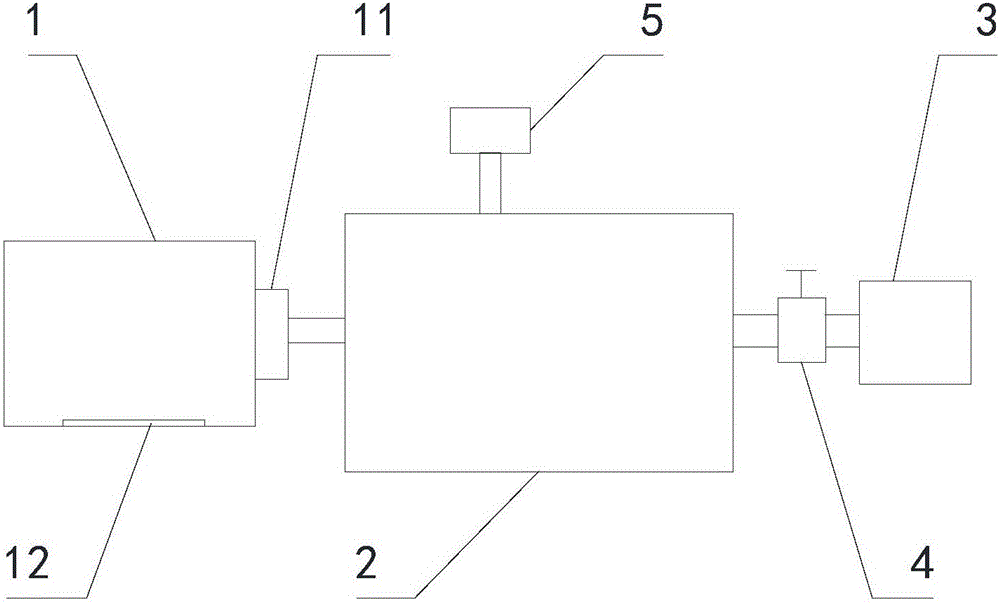

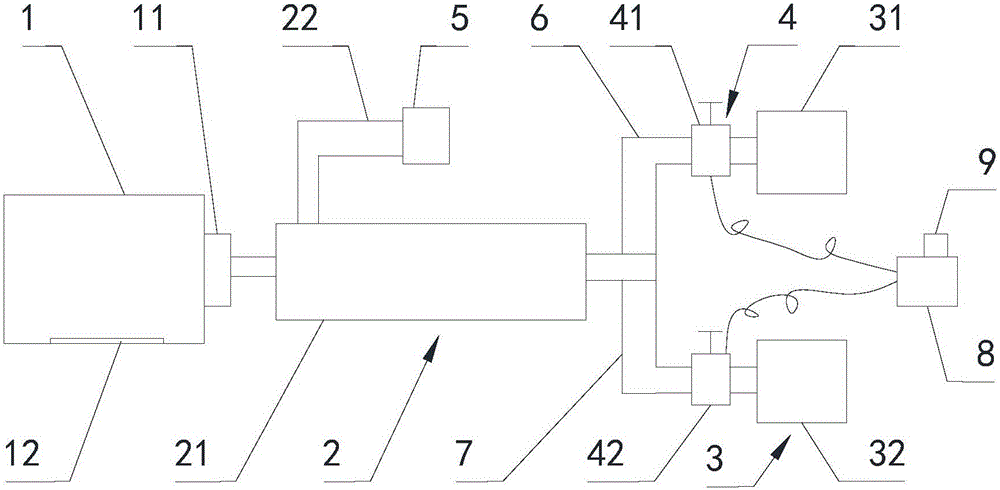

Pulverizer special for lithium battery cathode material and closed-loop cyclic pulverizing system of pulverizer

The invention discloses a pulverizer special for a lithium battery cathode material and a closed-loop cyclic pulverizing system of the pulverizer. The system comprises the pulverizer special for the lithium battery cathode material; a feeding device is connected to a feeding pipe of the pulverizer, and a discharging pipe is sequentially connected with a cyclone collector, a pulse dust remover and an induced draft fan through a connecting pipeline; an outlet of the induced draft fan is connected to an air inlet pipe through the connecting pipeline, and an air inlet of the induced draft fan is provided with an inert gas input pipeline in a parallel-connection manner; and an inert gas source is connected to the inert gas input pipeline. The pulverizer has the advantages of a mechanical pulverizer and advantages of a gas flow pulverizer, the whole system carries out sealed pulverizing, the inert gas can be recycled, the intake water is little, the noise is low, the production process is clean and environment-friendly, collection and recycling of the inert gas can be achieved, the water intake of the whole system is little, and the oxygen content is controllable. According to the pulverizer and the pulverizing system of the pulverizer, under the condition that the inert gas does not need to be inflated for protection, air recycling can be achieved, and the water intake can be reduced to the maximum extent.

Owner:山东埃尔派粉体科技股份有限公司

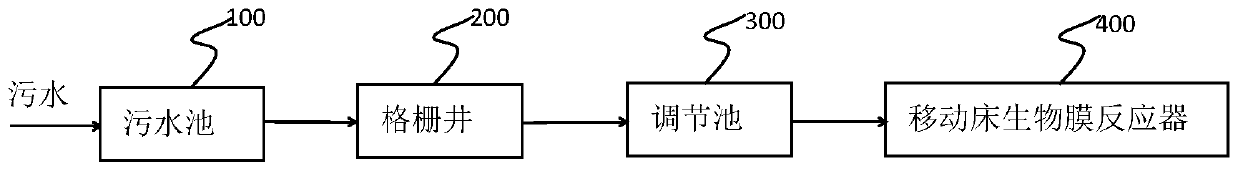

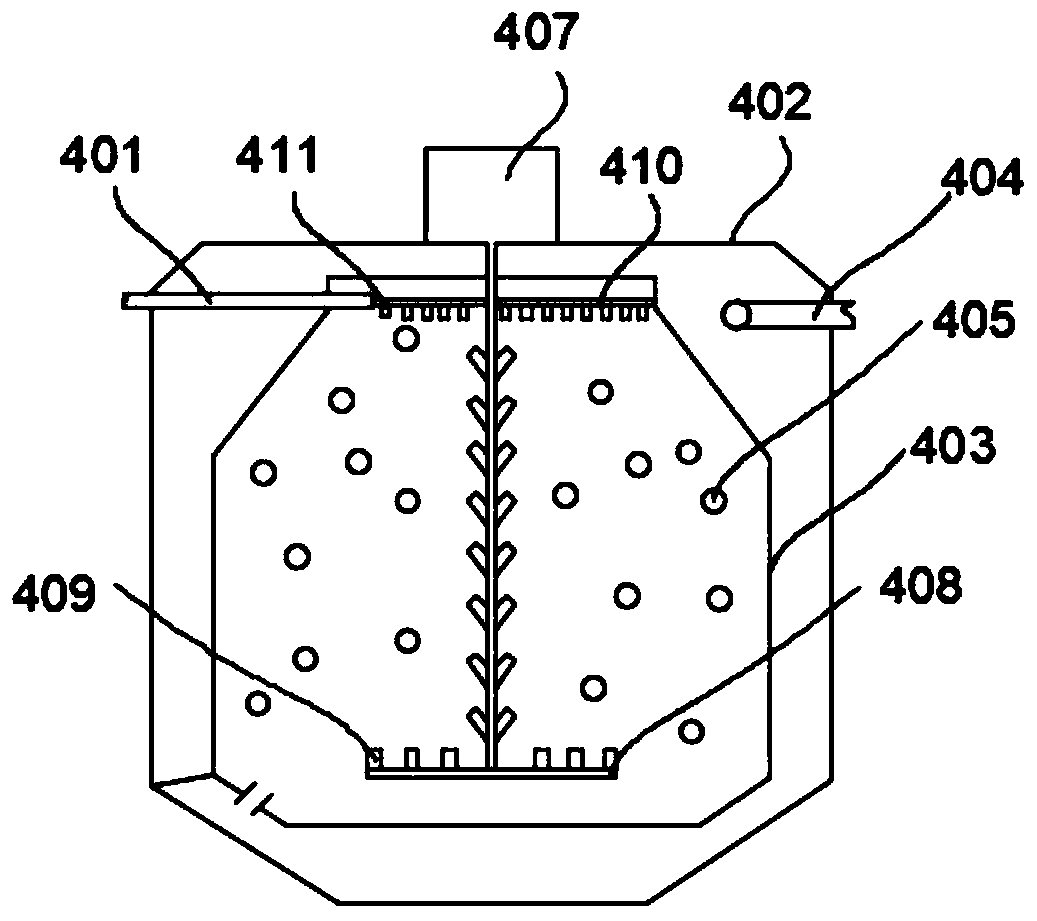

Moving bed biofilm reaction system

InactiveCN111592102AControllable oxygen contentImprove processing efficiencyWater treatment parameter controlTreatment using aerobic processesBiofilmAnaerobic reactor

The invention discloses a moving bed biofilm reaction system, and belongs to the technical field of sewage treatment. The moving bed biofilm reaction system comprises: a first water inlet pipe; an anoxic reactor communicated with the first water inlet pipe; an anaerobic reactor communicated with the anoxic reactor; and the aerobic reactor is communicated with the anaerobic reactor. The system solves the problems of low sewage treatment efficiency and poor quality of a moving bed biofilm reaction system.

Owner:深圳市辰中环境技术有限公司 +1

A method for reducing coal consumption and water recovery of coal-fired generating units by using coal drying and exhaust steam

ActiveCN103968659BReduce coal consumption for power supplyIncrease temperatureDrying solid materialsWater vaporProcess engineering

The invention relates to a method of utilizing coal drying exhaust steam to reduce coal consumption of a coal-fired power generator set and recovering water. The method is to add a heat and water recovery system between a coal drying system and the coal-fired power generator set, wherein the heat and water recovery system can convert heat and water vapor carried by the dry tail gas to heat and water carried by hot water, and then the hot water carrying a lot of heat is used for preheating carrier gas entering the coal drying system, air entering a coal-fired boiler system and condensed water after condensing steam by a steam turbine in order to realize efficient transfer of the heat carried by the dry tail gas to the coal-fired power generator set, reduce the coal consumption for the coal-fired power generator set and recover water. The method is characterized by completely recovering and utilizing heat and water vapor carried by the dry tail gas, so as to obviously reduce the coal consumption of a power plant, and conform to the national industry policy of energy conservation and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Animal hood noninvasive oxygen inhalation device

PendingCN113244015AOptimize the way of non-invasive oxygen supplyFully contactedVeterinary instrumentsNoseCatheter

The invention provides an animal hood noninvasive oxygen inhalation device. The device comprises a hood body without a bottom cover, wherein the hood body is used for covering the head of an animal; a neck clamping unit is arranged on one side of the hood body and used for clamping the neck of the animal; the hood body is provided with an air inlet and an air outlet; and the air inlet is detachably connected with an oxygen catheter and used for delivering oxygen into the hood body. The device is easy and convenient to operate and high in practicability, the oxygen inhalation requirement of the animal is considered, and the animal noninvasive oxygen supply mode is optimized. During use, oxygen enters from the head side and makes full contact with the mouth and nose of the animal. Compared with nasal catheter oxygen inhalation, the hood oxygen inhalation airflow is gentle, and the oxygen content in the hood is relatively controllable.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +1

Pulverized coal gasification pulverization and water recovery integrated system and method for high-moisture coal

ActiveCN103234214BReduce water dischargeTake advantage ofDrying solid materials with heatIndirect carbon-dioxide mitigationVacuum pumpMoisture

The invention relates to a powder coal gasification powder processing and water recovery integrated system for high-moisture coal. The system comprises a steam indirect heat transfer drying machine, an absorption tower, a flash tower, a vacuum pump / Venturi injection pump and a raw coal bunker. The steam indirect heat transfer drying machine is connected with the raw coal bunker, a bag-type dust collector I and a surge bunker; the surge bunker is connected with a coal mill; the coal mill is connected with a hot blast heater, and a bag-type dust collector II and a delivery pipe II are arranged at the top of the coal mill respectively; the top of the absorption tower is connected with a carrier gas initial heater, a circulating pump is arranged at the bottom, and the side of the absorption tower is connected with the flash tower; the circulating pump is connected with an air heater and connected with the carrier gas initial heater; the air heater is connected with the flash tower and the hot blast heater respectively; the flash tower is connected with a condenser which is connected with the vacuum pump / Venturi injection pump; and the flash tower is connected with the carrier gas initial heater. The invention further discloses an application method of the system. According to the system and the method, the investment is small, and energy consumption can be reduced effectively.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Production line and production process of a low-oxygen cemented carbide mixture

The present invention relates to a production line of cemented carbide mixture with low oxygen content. The production line is composed of a reduction part for preparing blue tungsten powder, a reduction part for preparing tungsten powder, a carbonization part and a granulation part to form a closed system; the present invention The production line can make the nano-tungsten trioxide be in the closed production line from the inlet of the rotary reduction furnace at the starting end to the outlet of the spray drying tower at the end. The closed production line is filled with nitrogen or hydrogen, so that the nano-powder will never contact the outside air, thereby reducing the particle size of the nano-WC and preventing the oxidation and spontaneous combustion of the nano-WC, reducing the oxygen content of the cemented carbide mixture, and improving the ultra-fine particle size. The stability and controllability of the quality of the crystalline carbide can be improved, and the overall performance of the alloy can be improved.

Owner:UNIV OF SCI & TECH BEIJING

A kind of nitrogen airtight cycle pva powder making method

The invention relates to a nitrogen gas sealed circulating PVA powder processing method. The method comprises the following steps: (1) after a PVA polymer or resin passes through a rotary gas locking device I, the PVA polymer or resin is continuously and uniformly added into a crusher to obtain PVA particles; (2) nitrogen gas is conveyed into the crusher, the PVA particles are conveyed into a grading device to be graded to obtain large-particle PVA and nitrogen gas containing qualified PVA particles, and the large-particle PVA falls into the crusher to be crushed again; (3) the nitrogen gas containing the qualified PVA particles enters a cloth bag dust remover to be subjected to gas-solid separation to obtain fine powder and separated nitrogen gas, and the fine powder passes through a rotary gas locking device II to enter a stock bin; (4) the separated nitrogen gas enters a condenser to be subjected to indirect cooling with a cooling medium to obtain condensed nitrogen gas and condensate water; and (5) the condensed nitrogen gas is boosted by a circulating draught fan and then enters the crusher to be circularly utilized in a sealed manner. The nitrogen gas sealed circulating PVA powder processing method has the characteristics of safety and low energy consumption.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

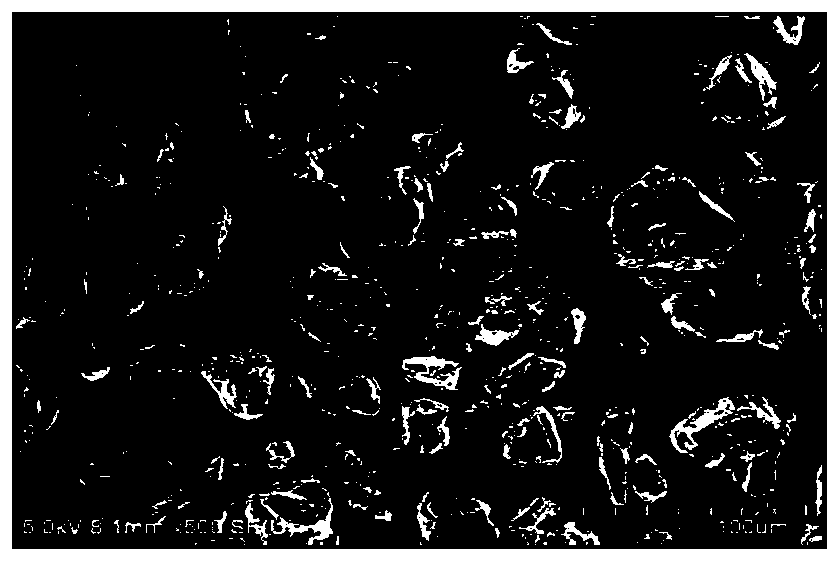

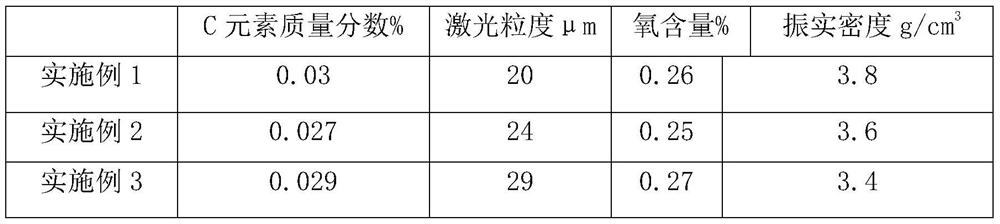

Low-tap-density 316 powder and preparation method thereof

InactiveCN111705271AControllable oxygen contentHigh mechanical strengthOxygen contentUltimate tensile strength

The invention discloses low-tap-density 316 powder. The low-tap-density 316 powder consists of the following alloy elements in percentage by mass: 0.3-1.0% of Si, 16-18% of Cr, 0.3-1.2% of Mn, 12-14%of Ni and the balance of Fe. The powder is controllable in powder oxygen content, is low in impurity content, and has an element C with mass fraction smaller than or equal to 0.03%. The powder has anirregular morphology, is high in finished product mechanical strength after being pressed and sintered, is good in gas permeability, is resistant to a high temperature, and is wider in filter precision range. Moreover, a laser particle size is 20-30[mu]m, oxygen content is smaller than 0.28%, and tap density is smaller than or equal to 3.8 g / cm<3>.

Owner:江苏萌达新材料科技有限公司

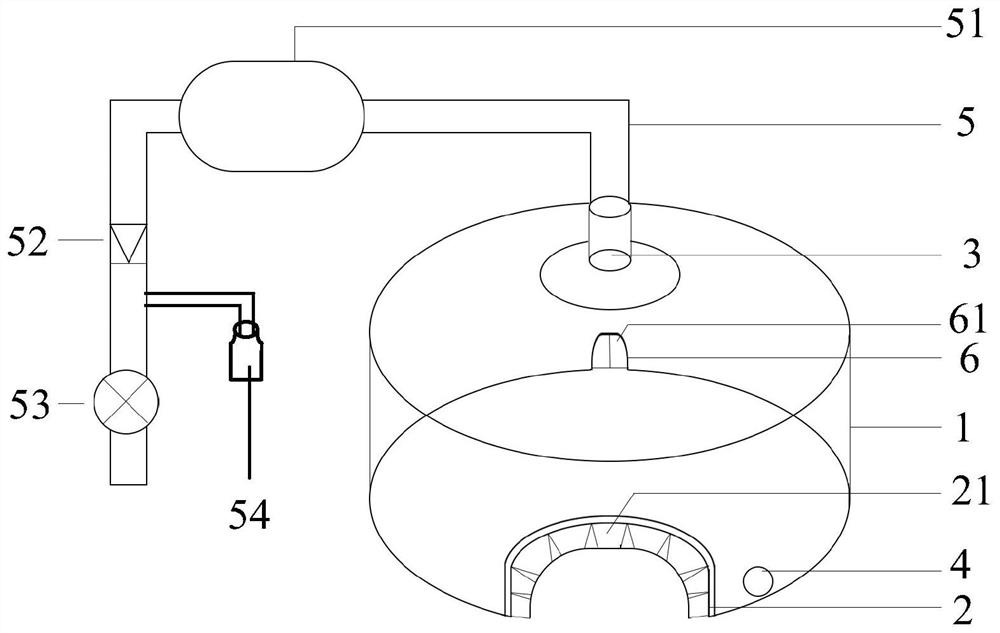

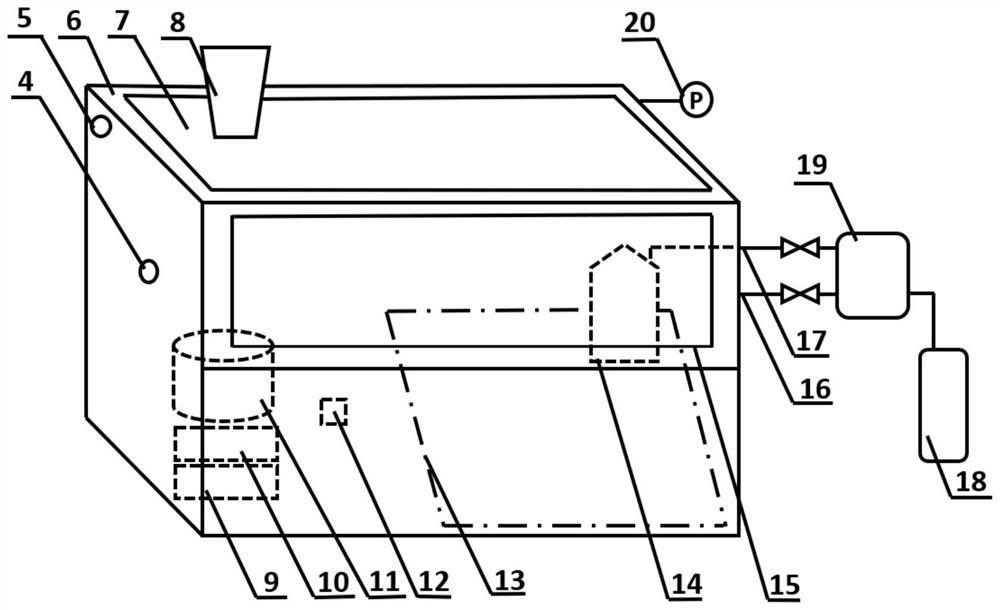

Animal model preparation system for obstructive sleep breathing disorder

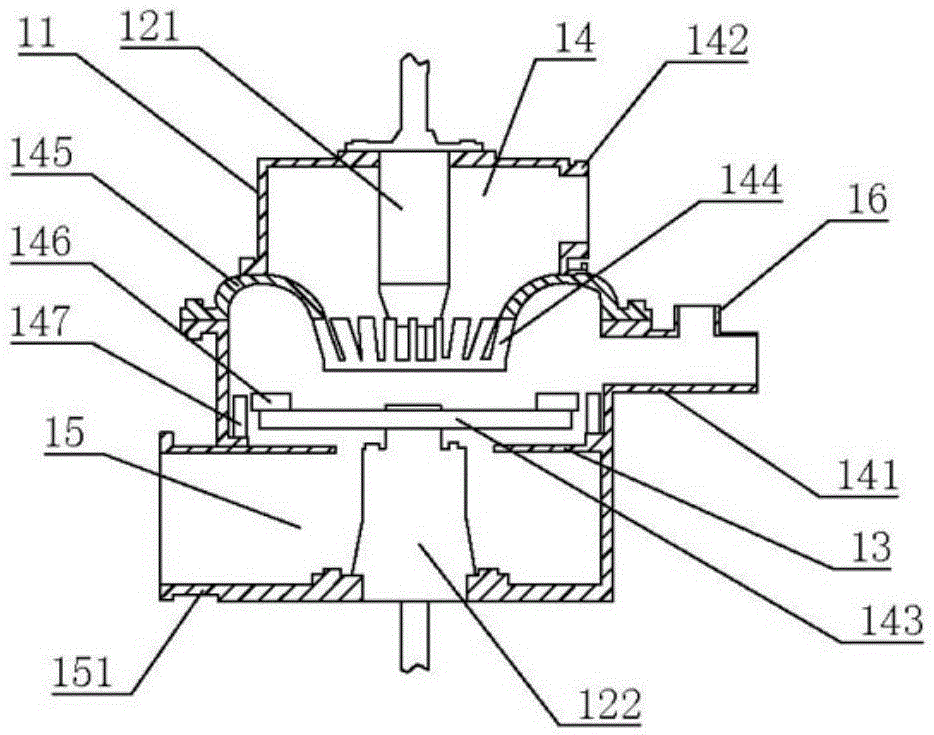

ActiveCN105726156BPressure is easy to controlControllable oxygen contentVeterinary instrumentsDiseasePressure stabilization

The invention relates to the technical field of medical experiment, in particular to an obstructive sleep respiratory disorder disease animal model preparation system. The obstructive sleep respiratory disorder disease animal model preparation system comprises a head cap and a simulation container device, wherein the first end of the simulation container device is communicated with the inside of the head cap; the corresponding second end of the simulation container device is used for connecting an air source; a first valve is arranged between the simulation container device and the air source; one end of the head cap is open; the head cap is used for externally sleeving on a target animal; the opening of the head cap can be connected with the neck part of the target animal in a sealed way; a pressure stabilization device is connected onto the simulation container device; the pressure stabilization device presets a pressure threshold value and is used for controlling the on-off state of an air path inside and outside the simulation container device. The invention aims at providing the obstructive sleep respiratory disorder disease animal model preparation system for improving the knowing and treatment on an obstructive sleep respiratory disorder disease.

Owner:于兆衍

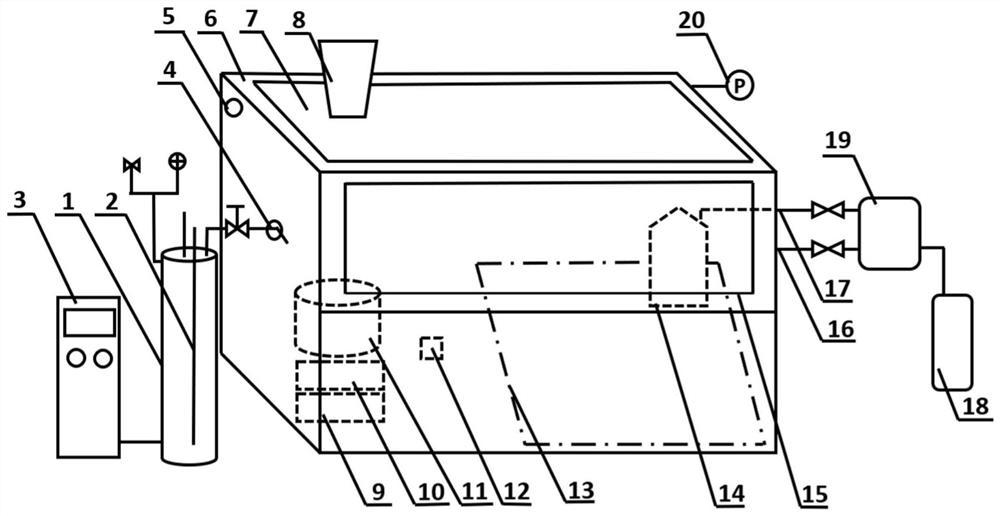

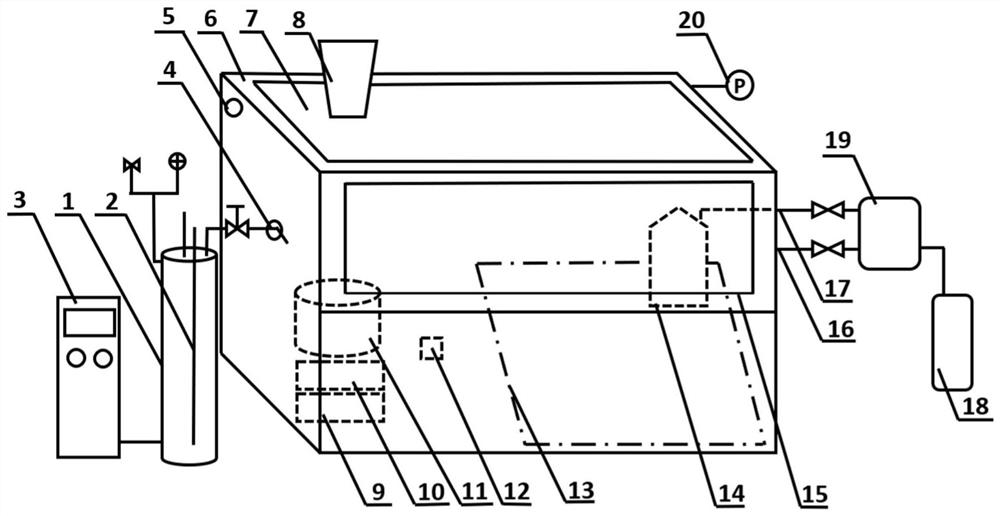

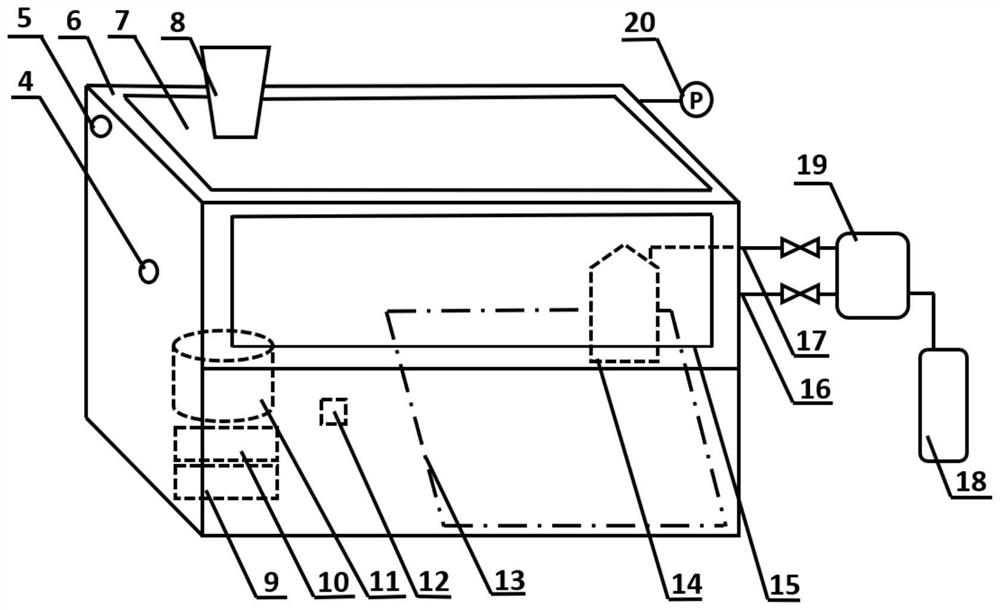

High-temperature sodium combustion reaction experimental device

ActiveCN112129881AConvenient for temperature detectionControllable oxygen contentChemical analysis using combustionPhysicsChemistry

The invention belongs to the technical field of chemical reaction devices, and relates to a high-temperature sodium combustion reaction experimental device. The experimental device comprises a sealedglove box, a gas access port, a reaction container, a sodium introduction port, a heating plate, a power supply, a balance, an aerosol storing container, an aerosol collection container, an aerosol collection pipeline, an aerosol collection port, an air pump, a gas storing pipeline, a gas collection port and a gas collection bag. The high-temperature sodium combustion reaction experimental devicecan be better used for experimental research of high-temperature sodium combustion reaction.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

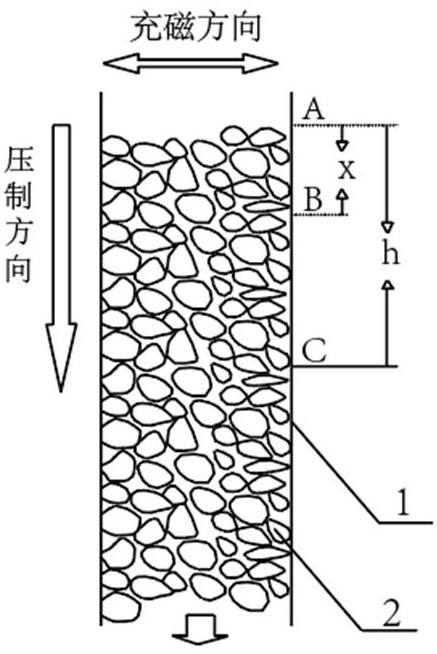

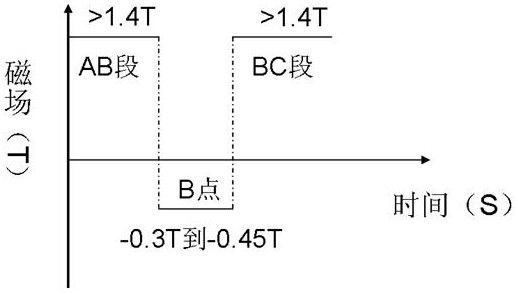

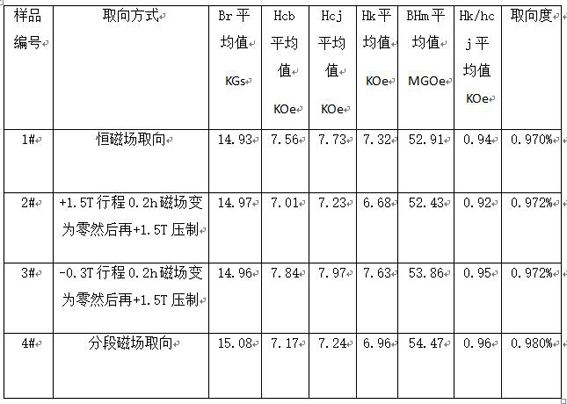

A kind of preparation method of high-performance sintered re-fe-b system

ActiveCN114242437BAvoid partialGood orientationInductances/transformers/magnets manufactureMagnetic materialsOxygen contentMetal mold

Owner:TIANJIN SANHUAN LUCKY NEW MATERIAL CO LTD +1

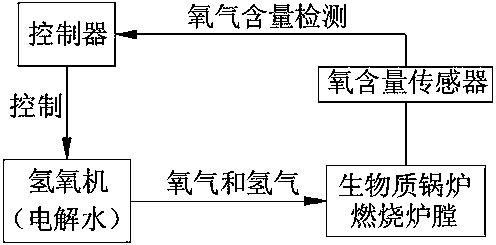

Biomass particle boiler combustion supporting control method

InactiveCN108361730ASufficient oxygenGuarantee fullyFuel supply regulationAutomotive engineeringFlue gas

The invention discloses a biomass particle boiler combustion supporting control method. An oxyhydrogen machine is used for electrolyzing water to generate oxygen and hydrogen, then mixed gas of the oxygen and the hydrogen is led into a hearth of a biomass boiler, on one hand, combustion of biomass particles can be accelerated, combustion is more sufficient, on the other hand, the mixed gas of theoxygen and the hydrogen can be burnt, a large amount of heat is generated, and more sufficient combustion of the biomass particles is facilitated; meanwhile, the combustion hearth of the biomass boiler is internally provided with an oxygen content sensor used for detecting the oxygen content, detected oxygen content signals are transmitted to a controller in real time through the oxygen content sensor, the controller can control whether the oxyhydrogen machine works or not according to the oxygen content. The biomass boiler is effectively combined with the oxyhydrogen machine, it can be guaranteed that the content of oxygen in the hearth of the biomass combustion boiler is sufficient, sufficient biomass particle combustion is guaranteed, flue gas discharge is reduced, and the using rate ofbiomass fuel is improved.

Owner:KINGKAR ECO TECH CO LTD

A high-temperature sodium combustion reaction experimental device

ActiveCN112129881BControllable oxygen contentControl oxygen contentChemical analysis using combustionChemical reactionAir pump

The invention belongs to the technical field of chemical reaction devices, and relates to a high-temperature sodium combustion reaction experimental device. The experimental device includes a sealed glove box, a gas inlet, a reaction vessel, a sodium inlet, a heating plate, a power supply, a balance, an aerosol collection container, an aerosol collection container, an aerosol collection pipeline, an aerosol collection port, Air suction pump, gas collection pipeline, gas collection port, gas collection bag. The high-temperature sodium combustion reaction experimental device of the present invention can be better used for the experimental research of high-temperature sodium combustion reaction.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Heat-resistant alloy steel powder for MIM, preparation method and equipment thereof

InactiveCN113245542AUniform compositionControllable oxygen contentChromium carbideUltimate tensile strength

The invention discloses heat-resistant alloy steel powder for MIM, a preparation method and equipment thereof. The heat-resistant alloy steel powder comprises the following components in percentage by by mass: 0.7 to 1.2 percent of Si, 24 to 27 percent of Cr, 0.2 to 1.2 percent of Mn, 1.0 to 1.5 percent of Nb, 19 to 22 percent of Ni, 0.3 to 0.7 percent of C, 0.2 to 0.6 percent of Ti and the balance Fe. The laser particle size is 7.0-9.0 [mu] m, the oxygen content is less than 0.4 percent, and the tap density is greater than or equal to 4.8 g / cm < 3 >. The powder provided by the invention is uniform in alloy component, controllable in oxygen content, low in impurity content and high in tap density, and the powder obtained through the method is similar to a sphere and is high in sintering density, high in high-temperature strength and good in corrosion resistance; the powder provided by the invention contains carbon-philic elements such as Ti and Nb, so that precipitation of chromium carbide is inhibited at high temperature, and meanwhile, the powder is resistant to acid and high in high-temperature strength; the powder prepared through water-gas combined atomization is low in oxygen content, fine and beneficial to sintering, and the product is high in density and good in appearance; and meanwhile, the powder sphericity is good, feeding is facilitated, shrinkage in the product sintering process is small, and the size precision is high.

Owner:江苏萌达新材料科技有限公司

A kind of low oxidation metal powder and its preparation method and sealed ball mill for preparation

The invention provides low oxidation metal powder, a preparation method thereof and a sealed ball mill used for preparing the low oxidation metal powder. The oxygen content of the low oxidation metal powder is smaller than 0.15%. The preparation method of the low oxidation metal powder comprises the following steps that S002, raw materials of the low oxidation metal powder are ground into powder, then the powder is subjected to dehydrogenation and deoxygenation treatment, and low oxidation metal powder agglomerates of which the oxygen content is smaller than 0.15% are obtained; and S004, the low oxidation metal powder agglomerates are ground into powder under the anaerobic condition, so that the low oxidation metal powder is obtained. The sealed ball mill used for preparing the low oxidation metal powder comprises a rack, a ball milling barrel and a motor. The rack is provided with a sealed barrel. One end of the sealed barrel is provided with an opening. The opening is provided with a sealing cover. The other end of the sealed barrel is provided with a shaft hole. The ball milling barrel is arranged in the sealed barrel. One end of the ball milling barrel is provided with a material opening. The material opening is provided with a material cover. The other end of the ball milling barrel is provided with a rotating shaft. The rotating shaft penetrates through the shaft hole and extends out to the outer side of the sealed barrel. A main shaft of the motor is in drive connection with the rotating shaft of the ball milling barrel through a transmission mechanism.

Owner:宝鸡泰力松新材料有限公司

Obstructive sleep respiratory disorder disease animal model preparation system

ActiveCN105726156APressure is easy to controlControllable oxygen contentVeterinary instrumentsDiseasePressure stabilization

The invention relates to the technical field of medical experiment, in particular to an obstructive sleep respiratory disorder disease animal model preparation system. The obstructive sleep respiratory disorder disease animal model preparation system comprises a head cap and a simulation container device, wherein the first end of the simulation container device is communicated with the inside of the head cap; the corresponding second end of the simulation container device is used for connecting an air source; a first valve is arranged between the simulation container device and the air source; one end of the head cap is open; the head cap is used for externally sleeving on a target animal; the opening of the head cap can be connected with the neck part of the target animal in a sealed way; a pressure stabilization device is connected onto the simulation container device; the pressure stabilization device presets a pressure threshold value and is used for controlling the on-off state of an air path inside and outside the simulation container device. The invention aims at providing the obstructive sleep respiratory disorder disease animal model preparation system for improving the knowing and treatment on an obstructive sleep respiratory disorder disease.

Owner:于兆衍

Continuous casting and rolling production process of oxygen-free copper rod

ActiveCN107214194BControllable oxygen contentImprove qualityMetal rolling arrangementsElectrolysisOxidation resistant

The invention discloses a continuous casting and rolling production process of an oxygen-free copper rod. The continuous casting and rolling production process comprises the following steps of putting electrolytic copper raw materials in a sealed mixing melting furnace for smelting, introducing reduction gas, then discharging from a copper outlet of the sealed mixing melting furnace, flowing into a molten copper casting ladle through a molten copper diversion trench, opening a casting gate of the molten copper casting ladle, continuously and uniformly pouring molten copper to a continuous casting crystallizer through a stainless steel pouring nozzle of the molten copper casting ladle so as to form a continuous casting copper ingot, quickly and uniformly applying oxidation resistant lubricating oil to the surface of the continuous casting copper ingot, sending to a rolling mill so as to be rolled into the oxygen-free copper rod, cooling the oxygen-free copper rod until the temperature of the oxygen-free copper rod is reduced below 80 DEG C, then wiping to remove the oxidation resistant oil from the surface of the oxygen-free copper rod, and then wiping the surface of the oxygen-free copper rod with a small amount of industrial alcohol so as to package and store. By adopting the continuous casting and rolling production process, the quality of the oxygen-free copper rod prepared by adopting the continuous casting and rolling process can be increased.

Owner:NANTONG MINGGUANG ELECTRIC WIRE

A method for smelting stainless steel by blowing hydrogen in an aod furnace

ActiveCN113373277BInhibits oxidation of chromiumImprove the effectProcess efficiency improvementSlagDecarburization

The invention discloses a method for smelting stainless steel by blowing hydrogen in an AOD furnace, belonging to the field of iron and steel metallurgy. When using AOD to smelt stainless steel, the method of top lance oxygen blowing + side lance hydrogen blowing or top lance hydrogen blowing + side lance oxygen blowing is used to deliver heat to the molten iron in the furnace during the decarburization period, so that the temperature of the molten iron in the furnace can quickly reach the preset temperature , to reduce the oxidation of chromium; at the same time, hydrogen can reduce the slag during the decarburization period, reducing the cost of reducing the alloy; during the reduction period, hydrogen is used instead of argon to reduce the cost of argon blowing; and hydrogen can reduce the slag, reducing the cost of reducing the alloy; while improving the end point Tapping temperature. The invention uses hydrogen blowing to smelt stainless steel, which can reduce the cost of smelting alloys, and at the same time, the hydrogen reaction product is water, which has a positive effect on alleviating the greenhouse effect.

Owner:UNIV OF SCI & TECH BEIJING

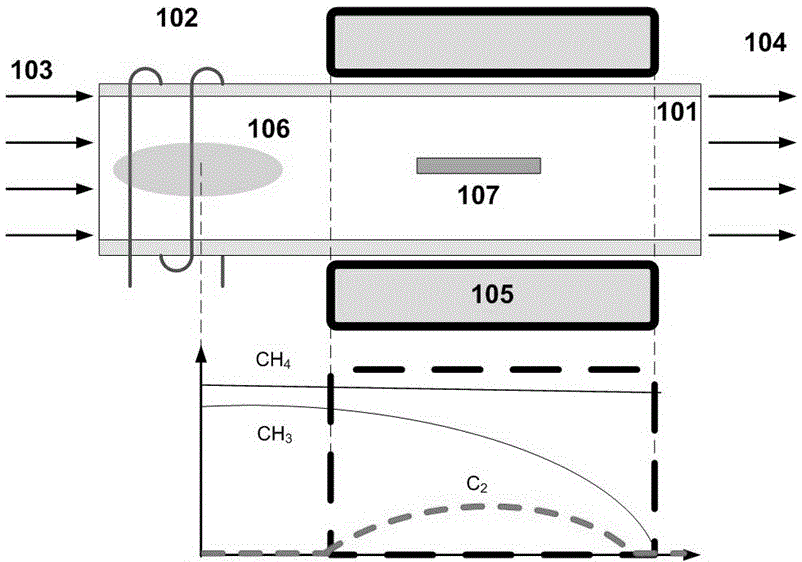

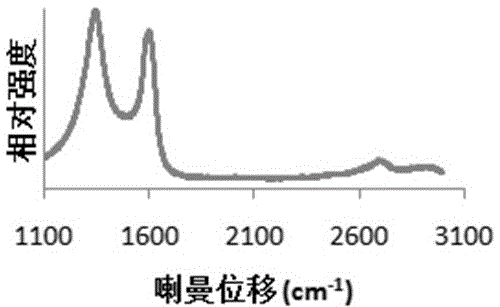

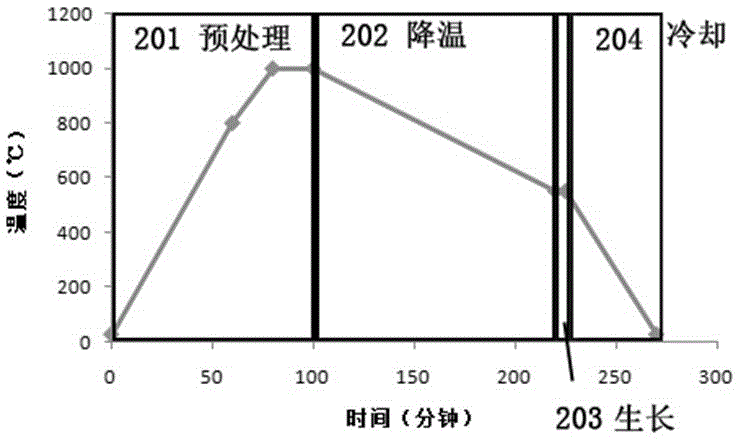

Direct synthesis of large-area graphene oxide based on plasma chemically enhanced vapor deposition

The invention belongs to the technical field of material science, and particularly relates to a method of directly synthesizing large-area graphene oxide based on plasma-enhanced chemical vapor deposition. The method comprises the following specific steps of pretreating a substrate; growing graphene oxide on the substrate by using a plasma-enhanced chemical vapor deposition system; after the growth is ended, taking out the graphene oxide, wherein the key point of synthesis is introduction and control of oxide atoms. The method disclosed by the invention is short in reaction time and low in reaction temperature; in addition, oxygen content of the graphene oxide is controllable. Compared with existing graphene oxide synthesized by a chemical method, the graphene oxide synthesized by the method disclosed by the invention has the characteristics of large size and good uniformity in size, and can be applied to the fields of gas detection, photoelectric devices and the like.

Owner:FUDAN UNIV

Double-air supply airflow mill

The invention relates to a double-air supply airflow mill which is used for powder making of magnetic materials. The double-air supply airflow mill comprises a main machine, a separator, a filter anda compressor which are sequentially distributed and connected, the air outlet of the filter is connected with the air inlet of the compressor through an air return pipe, the air outlet of the compressor is connected with the air inlet of a spraying nozzle in the main machine through a high pressure air supply pipe. The double-air supply airflow mill is characterized by further comprising a draughtfan, the main machine is provided with at least one low pressure air inlet, the low pressure air inlet of the main machine is connected with the air exhaust of the draught fan through a low pressureair supply pipe, and the air inlet of the draught fan is connected with the air return pipe; and a bypass pipe is connected between the low pressure air supply pipe and the air return pipe and is provided with an adjusting valve. The double-air supply airflow mill is high in powder milling quality, and the made powder size distribution is concentrated.

Owner:吉林市凯尔维特机电设备有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com